Power inverter

A power conversion device and electric conversion technology, applied in the direction of output power conversion devices, circuits, electrical components, etc., can solve the problems of large components, increased number of parts, and increased costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

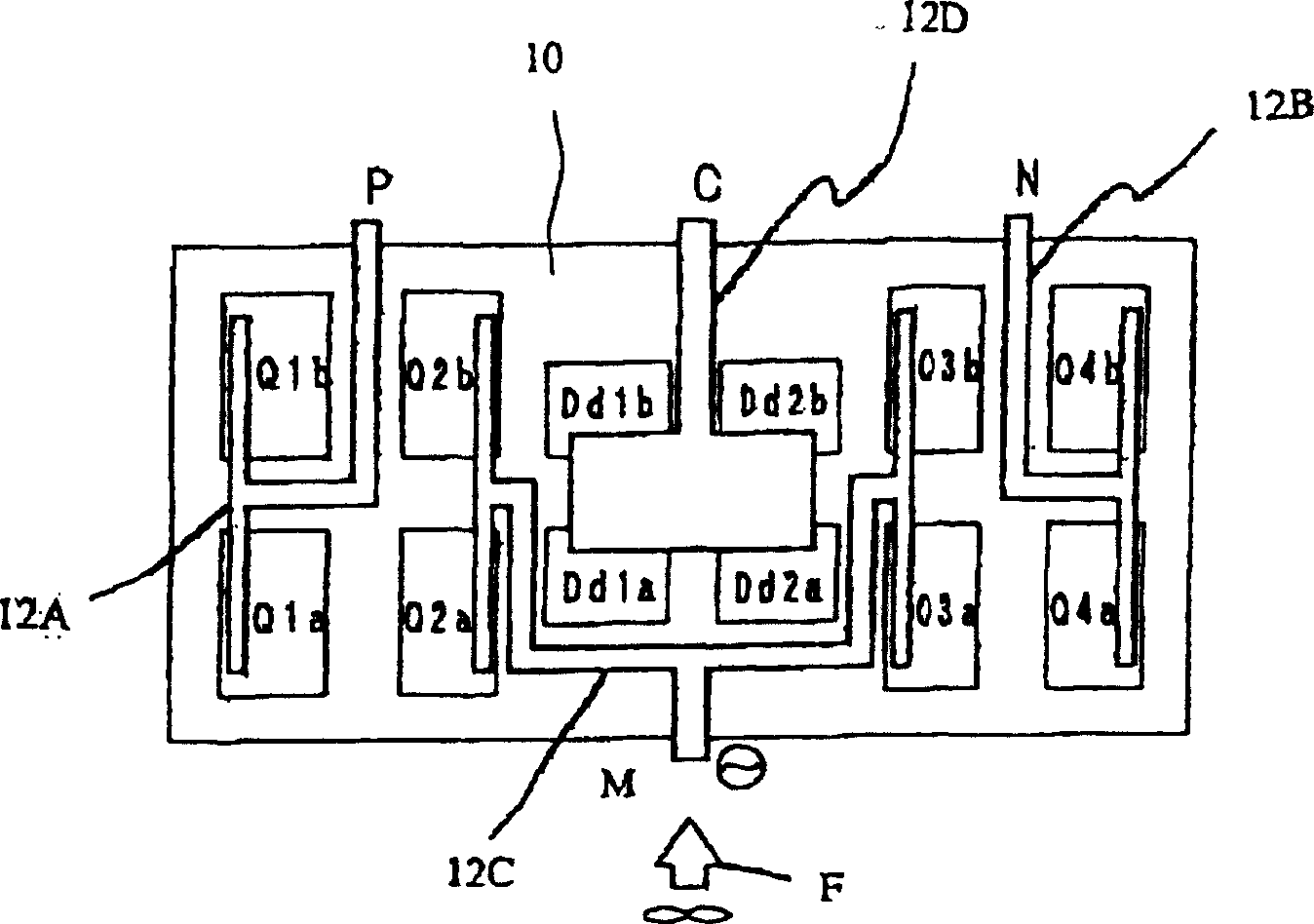

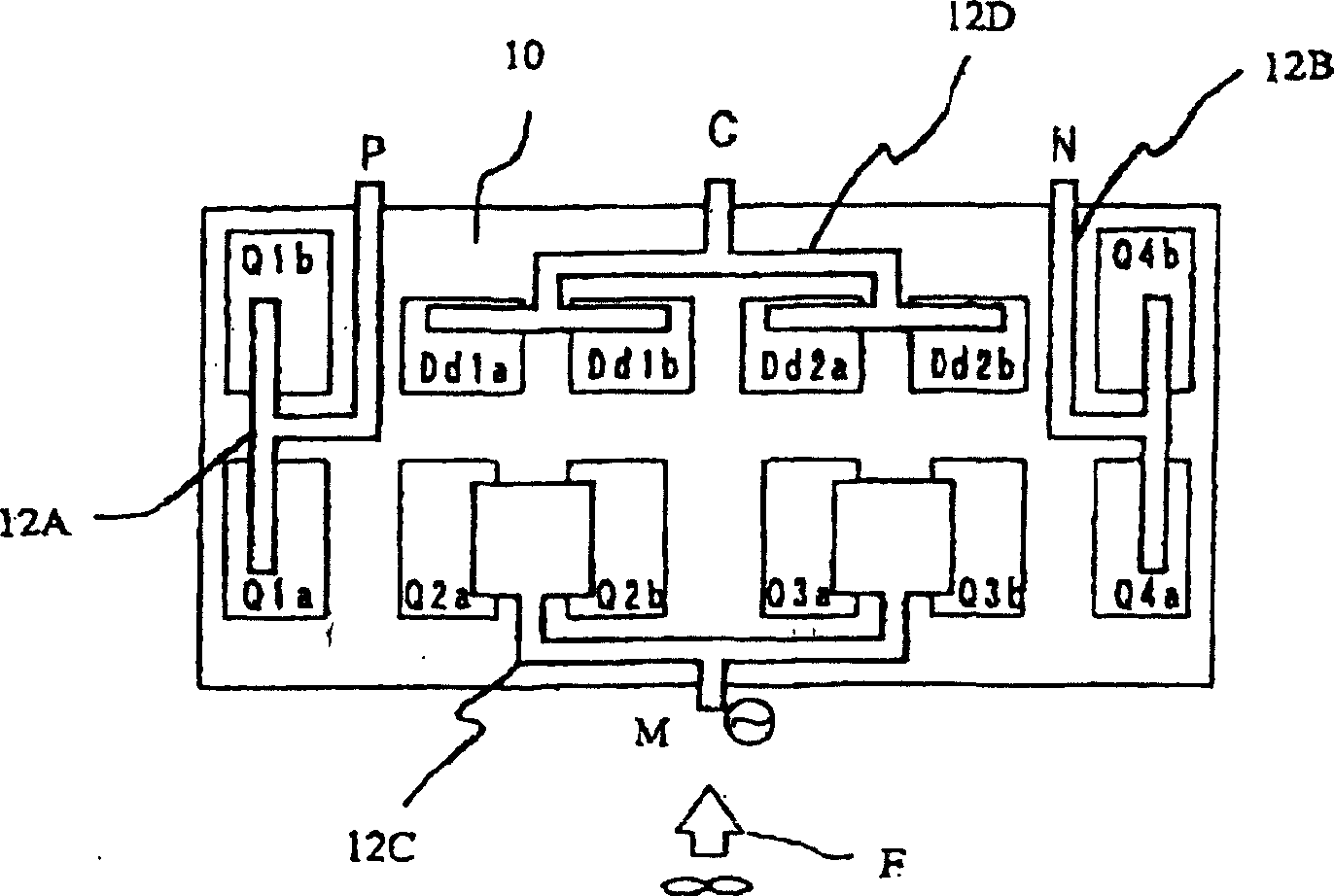

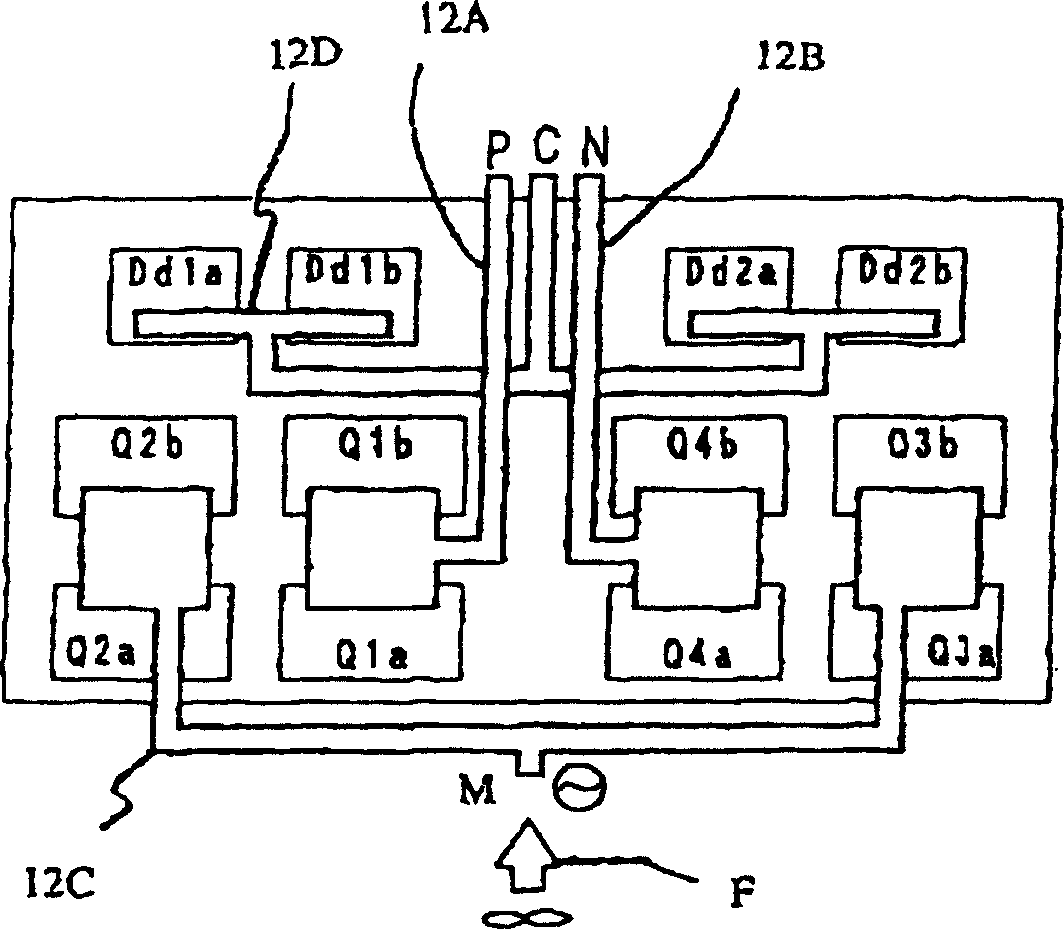

[0044] Embodiments of the present invention are described below. figure 1 It is an arrangement diagram of the semiconductor element Q and the diode Dd on one cooler in the power conversion device according to the first embodiment of the present invention. exist figure 1 In , a circuit of a single-phase part in a forward conversion circuit having a system a and a system b in a 2-column structure is shown.

[0045] Such as figure 1 As shown, each semiconductor element Q is mounted in such a direction that both of its short sides face the wind flow F. As shown in FIG. The first diode Dd1 and the second diode Dd2 with small heat loss are arranged in the central part of the heat receiving part 10, and the system a side is arranged upstream of the wind along the direction of the wind flow F, and the system b is arranged downstream of the wind. That is, the first diode Dd1a of system a is installed on the upstream side of the wind, the first diode Dd1b of system b is installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com