Substrate applying device

A technology for laminating devices and substrates, which is applied in the directions of contacts, optics, instruments, etc., can solve problems such as substrate pollution, and achieve the effects of avoiding pollution and eliminating static electricity accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

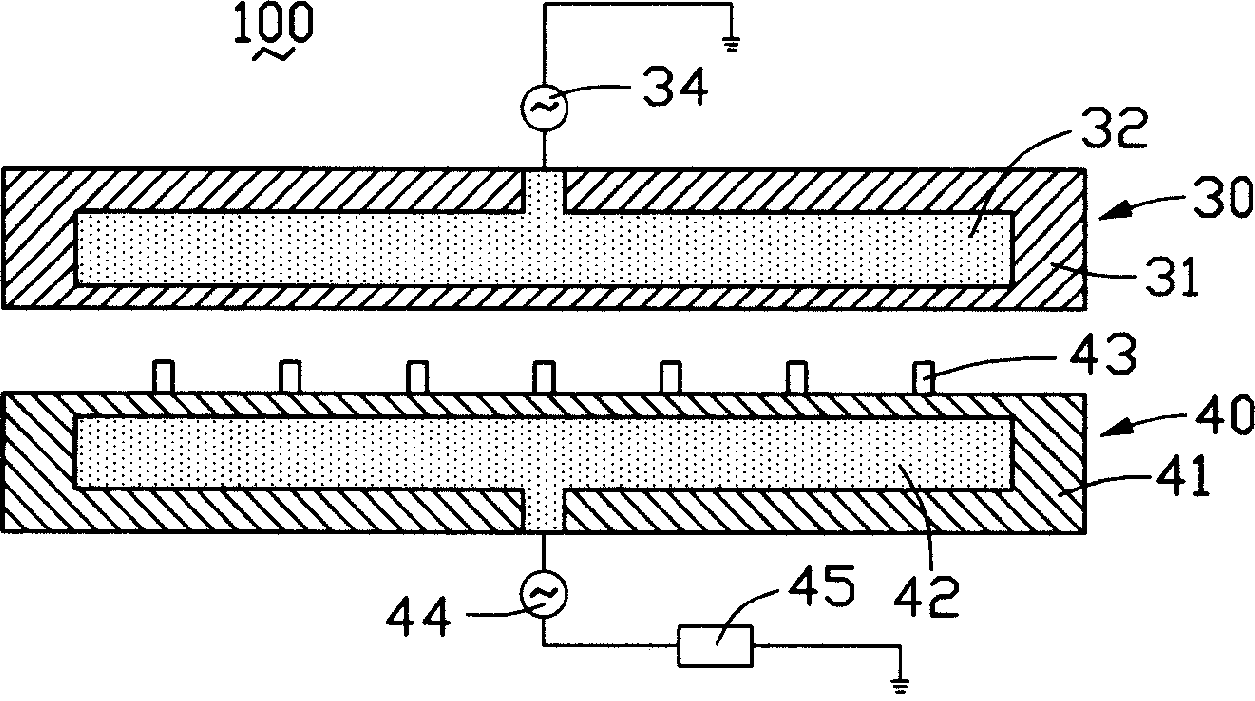

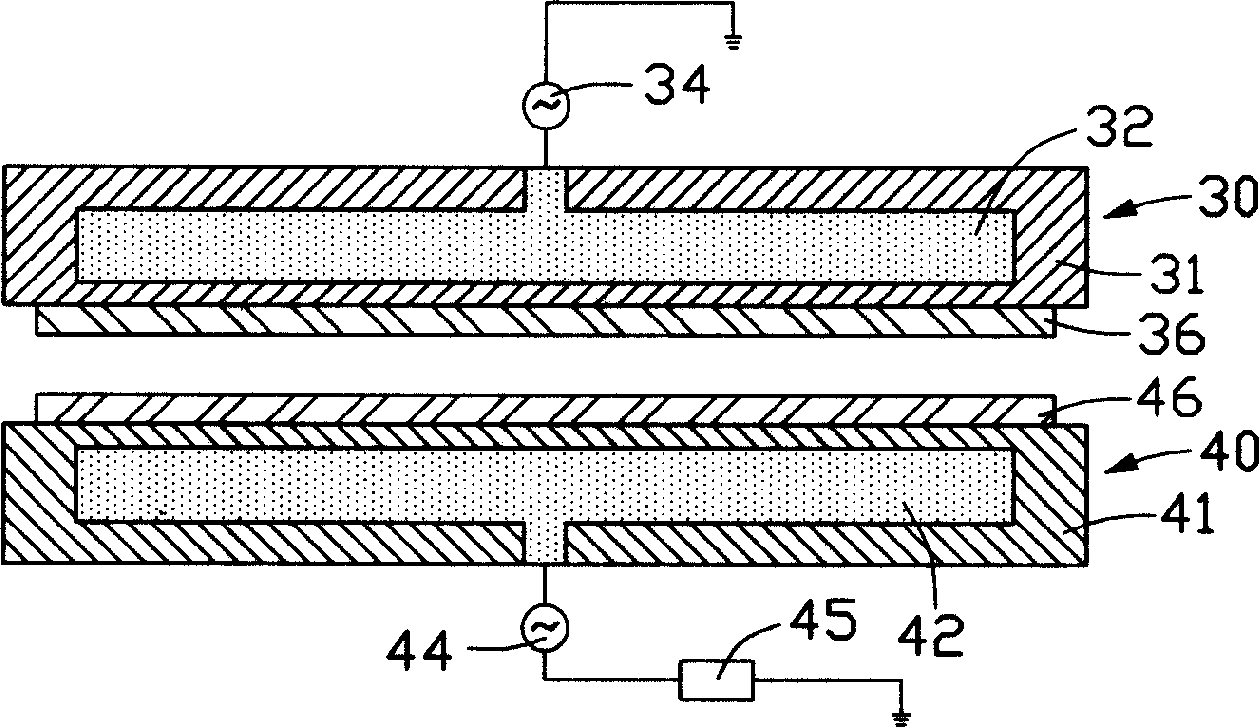

[0012] Such as figure 2 Shown is a cross-sectional view of the substrate laminating device of the present invention. The substrate bonding apparatus 100 includes a first electrostatic chuck 30 , a second electrostatic chuck 40 and a controller 45 .

[0013] The first electrostatic chuck 30 includes a first chuck body 31 , a first electrode 32 disposed in the first chuck body 31 , and a first power source 34 connected to the first electrode 32 . The second electrostatic chuck 40 is disposed on the lower side of the first electrostatic chuck 30 , and includes a second chuck body 41 , a second electrode 42 disposed in the second chuck body 41 and a second power supply connected to the second electrode 42 44 , the second suction cup main body 41 is provided with a plurality of support columns 43 , and the support columns 43 can move up and down relative to the second suction cup main body 41 . The controller 45 is connected to the second power source 44 of the second electrosta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com