Ceramic resonator welding machine

A ceramic resonator and plug-in technology, which is applied in the field of automatic welding equipment, can solve the problems of time-consuming and eye-catching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

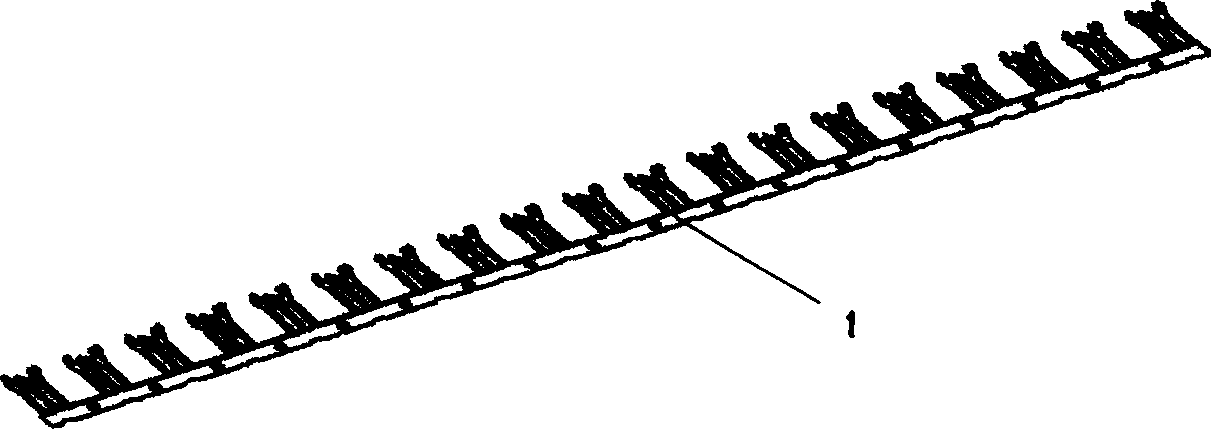

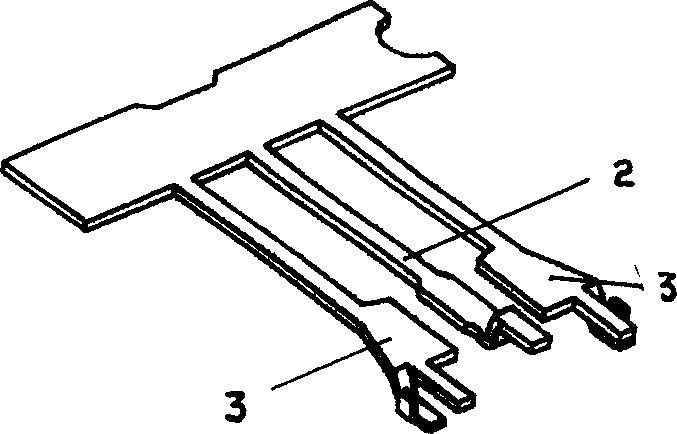

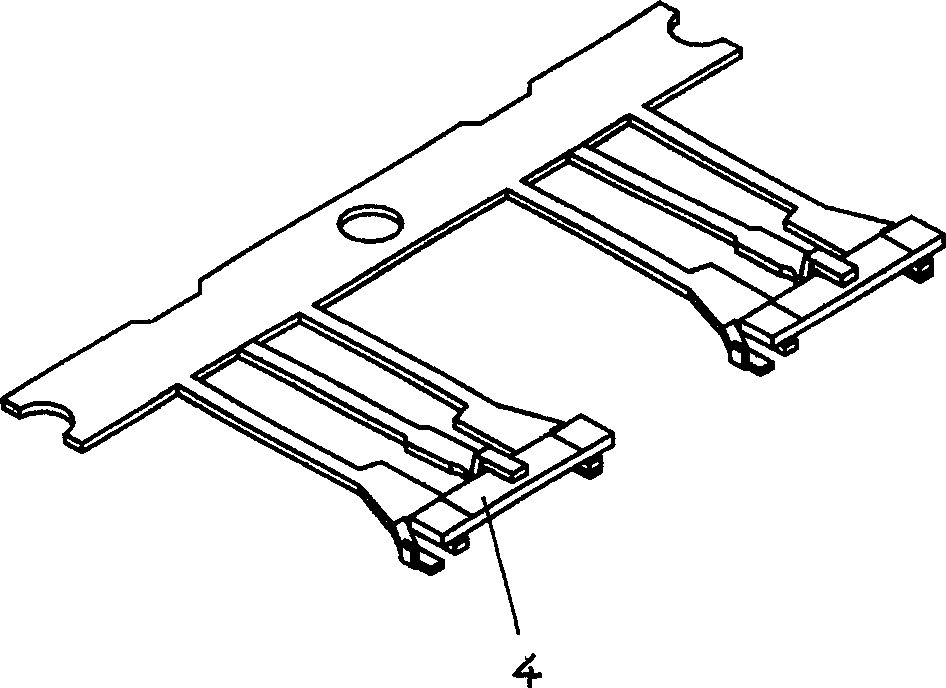

[0027] Such as figure 1 and figure 2 As shown, there are multiple sets of lead wires 1 on the lead wire of the ceramic resonator, and each set of lead wires has three wires, including two side pins 3 and one center pin 2 . Such as image 3 As shown, the task of the ceramic resonator welding machine of the present invention is to insert the ceramic resonator chip 4 into the three leads, and then weld solder on the contact between the center pin and the electrode of the chip.

[0028] The ceramic resonator welding machine includes a chip conveying device, a chip inserting mechanism, a welding device and a lead wire dynamic positioning device. Such as Figure 4 and Figure 5 As shown (for the convenience of expression, in Figure 4 and other several accompanying drawings provide a X-Y-Z three-dimensional coordinates as a frame of reference), the chip conveying device includes a spiral vibrating feeder 5, a linear vibrating feeder 6, a sheet-adding rod 7 and a rotary disc-ty...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com