Laser light path precollimator

A pre-alignment and optical path technology, applied in the field of laser applications, can solve problems such as reduced work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

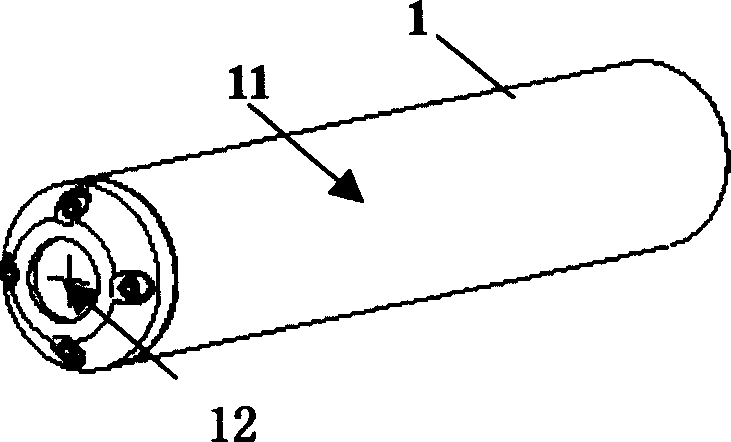

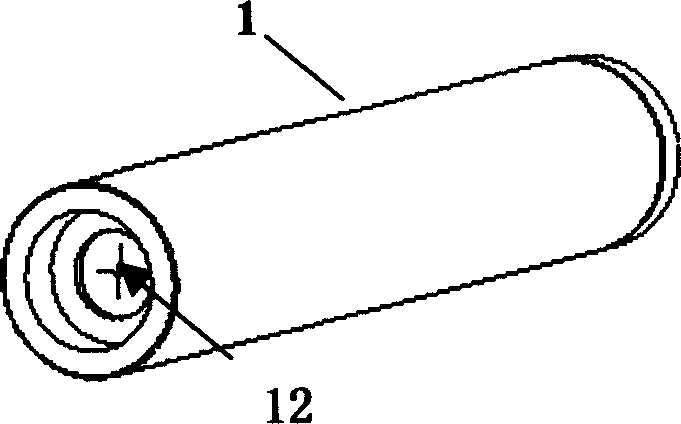

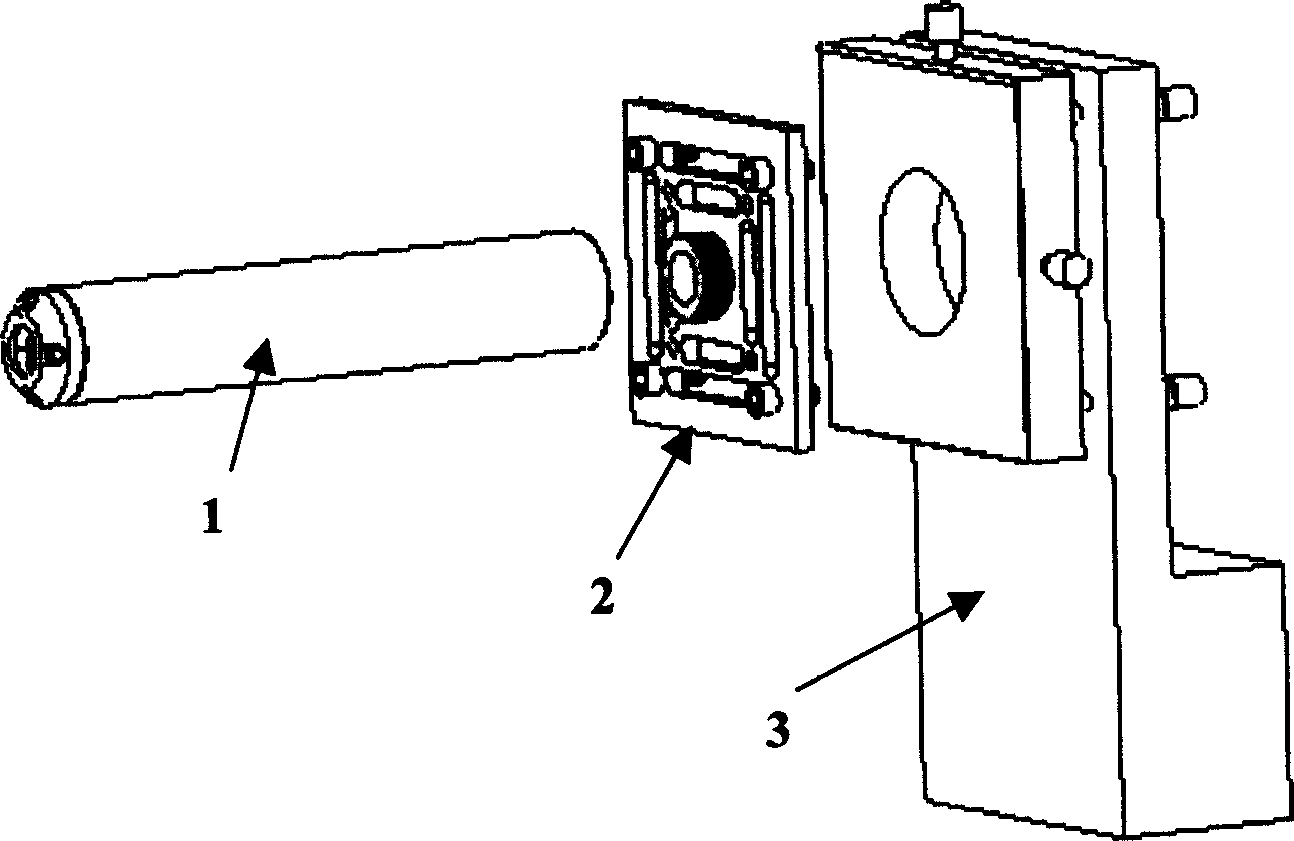

[0023] Embodiment one: crosshair type laser beam pre-aligner (such as figure 1 , 2 );

[0024] Such as figure 1 , 2 As shown: a cross wire 12 is respectively arranged at both ends of a section of hollow straight pipe 11 with a certain length. The line connecting the centers of the two cross wires is coincident (or parallel) with the axis of the straight pipe. When using, refer to image 3 : Fix the laser beam pre-aligner 1 on the alignment device 3 via the connection adapter device 2 . Adjust the alignment device so that the beam enters from one end (the center of the beam is located at the intersection of the cross wires as much as possible), and at the other end of the device, observe the degree of overlap of the two cross wires. According to the linear propagation characteristics of light and the principle that two points determine a line, adjust the dimensions of the alignment device. When the two cross wires coincide, the axis of the pre-aligner is basically paralle...

Embodiment 2

[0025] Embodiment two: iris type laser beam pre-aligner (such as Figure 4 );

[0026] Such as Figure 4 As shown: a diaphragm 42 is installed at both ends of a hollow straight tube 41 with a certain length (the adjustment range of the aperture of the diaphragm: 0.8-10mm), and the line connecting the centers of the two diaphragms coincides with the axis of the straight tube (or parallel). When using, refer to Figure 5 : Fix the laser beam pre-aligner 4 on the alignment device 6 via the connection adapter device 5 . The alignment device is adjusted so that the beam passes through one of the apertures, and at the other end of the device a power detector is used to detect the output energy. According to the linear propagation characteristics of light and the principle that two points determine a line, adjust the dimensions of the alignment device. When the detected power is maximum, the axis of the pre-aligner basically coincides with the central optical axis of the laser be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com