Wiping device, droplet discharge device, electro-optical device, method for manufacturing an electro-optical device, and electronic equipment

An electro-optical device and droplet nozzle technology, which is applied in the direction of instruments, identification devices, and devices for coating liquid on the surface, etc., can solve the problems of adverse effects of devices, waste of cleaning liquid, etc., and achieve high reliability and high quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

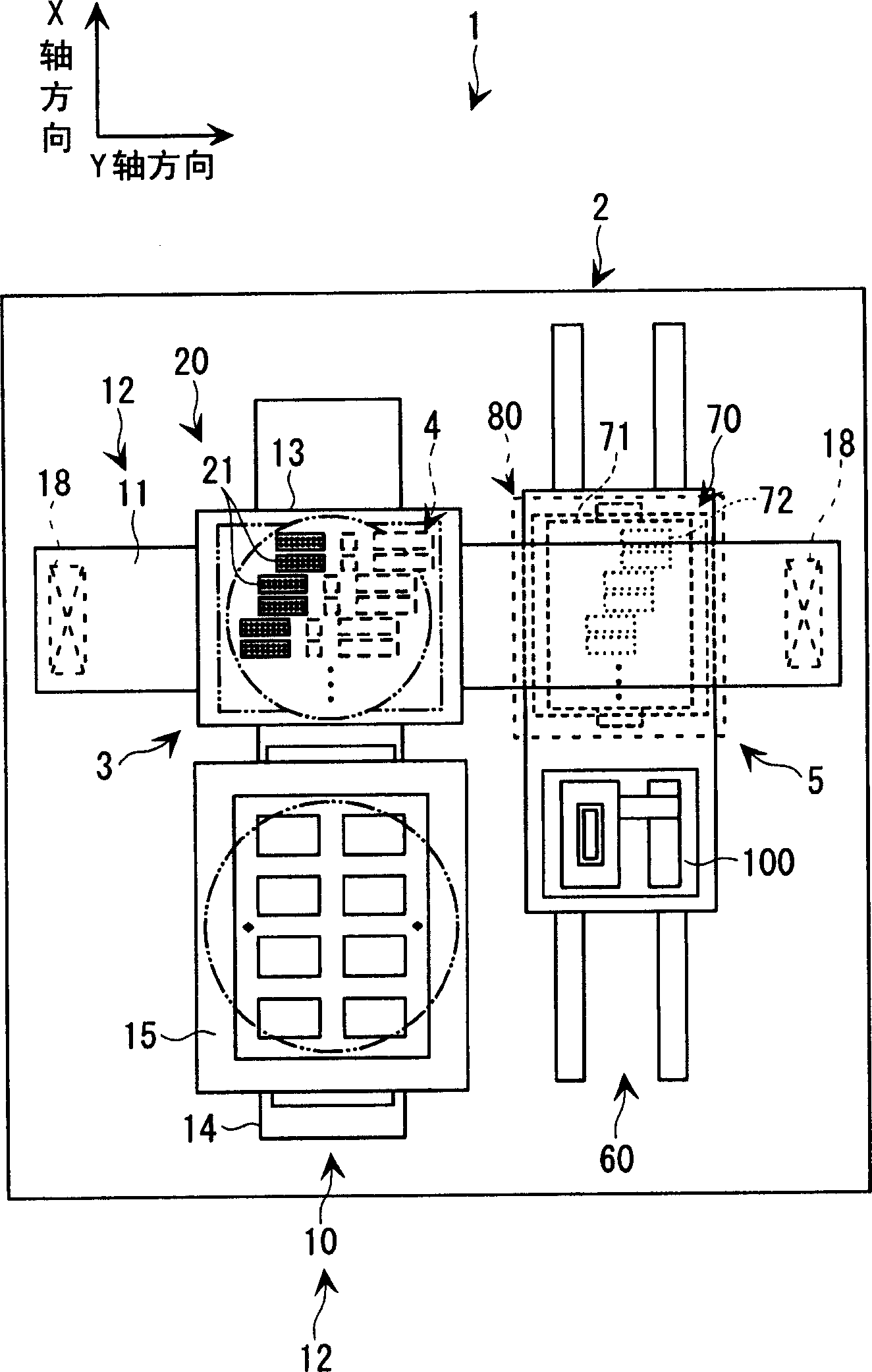

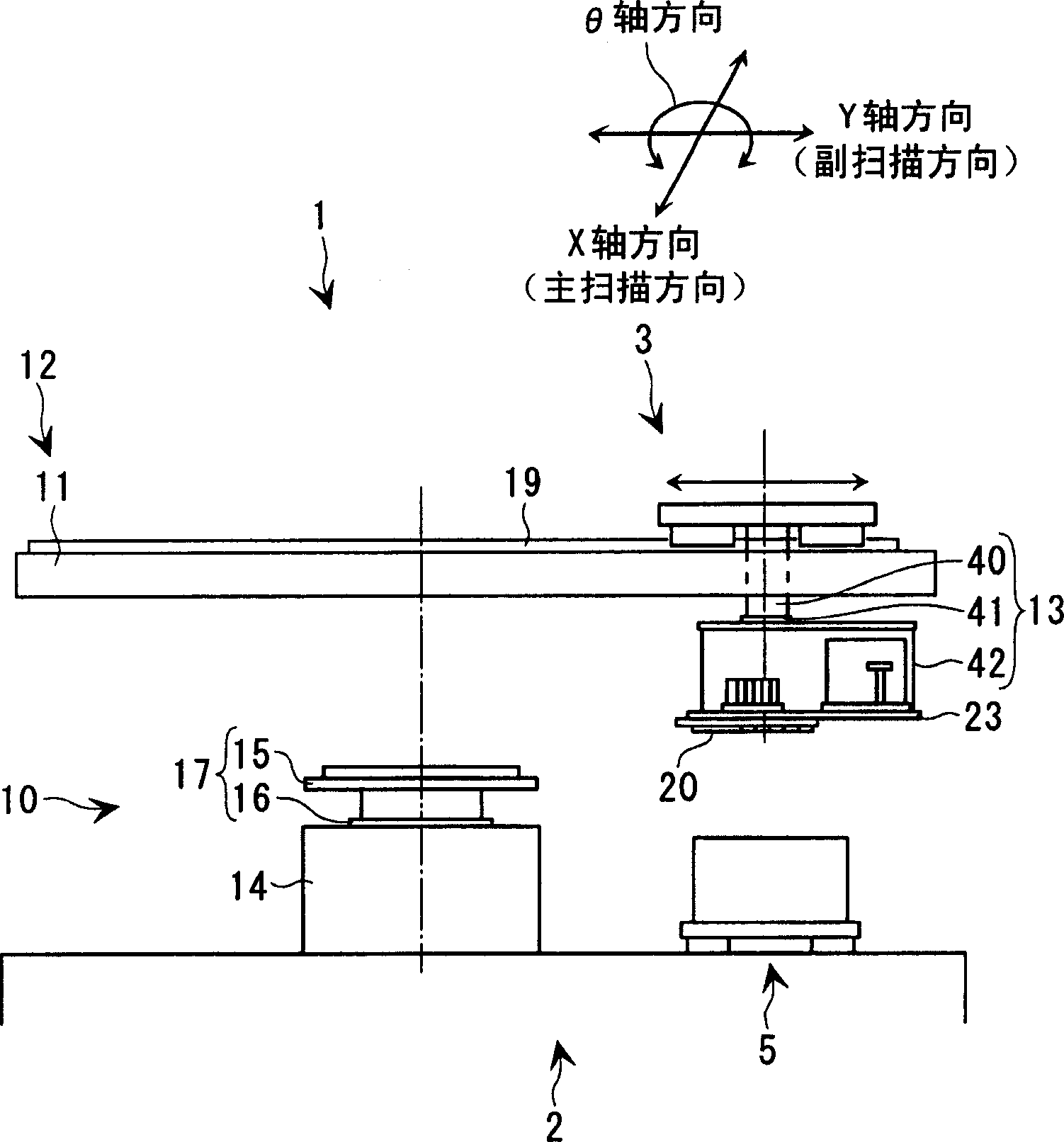

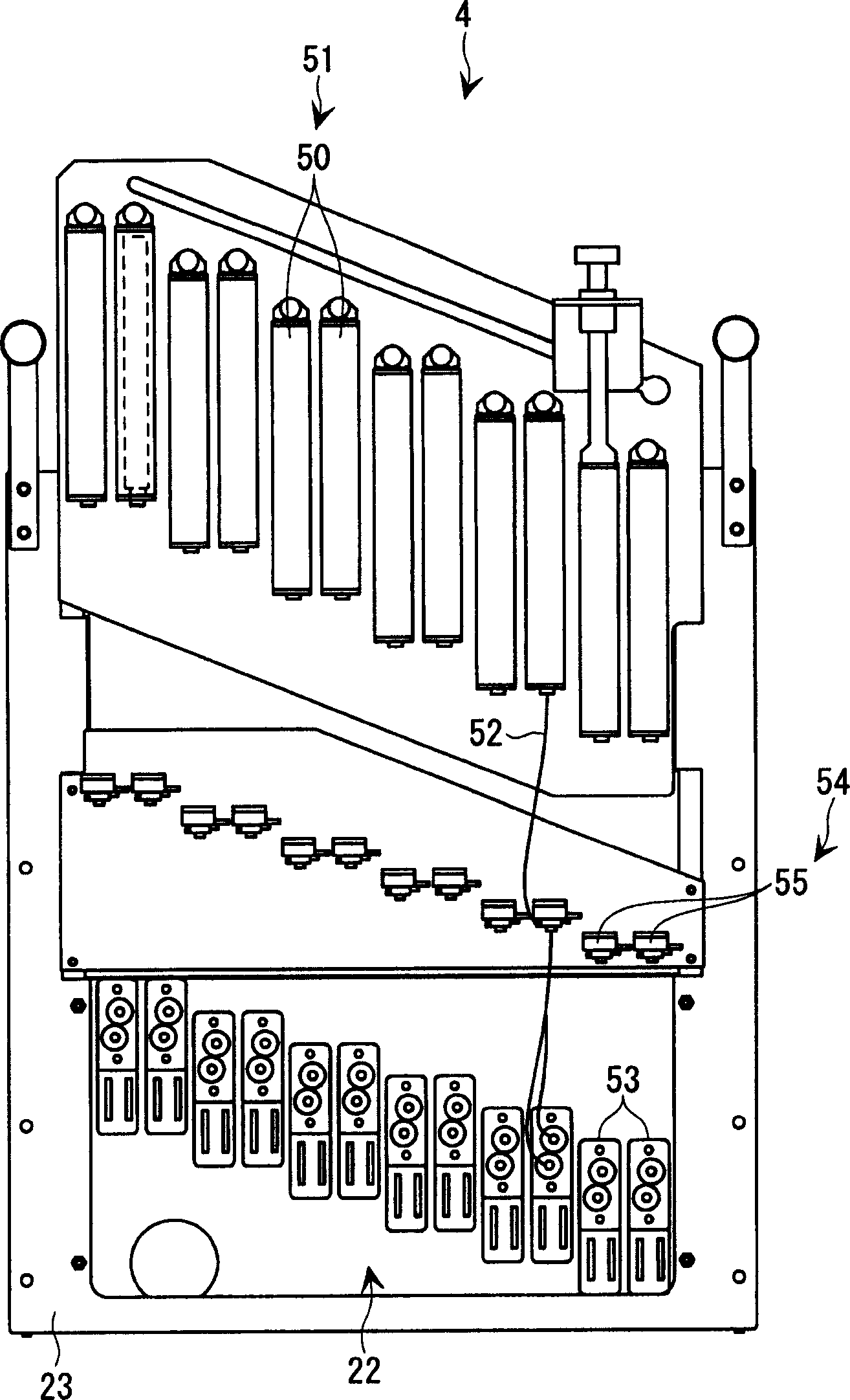

[0062] Such as figure 1 and figure 2 As shown, the drawing device 1 has a machine platform 2; a functional liquid drop ejection head 21, a droplet ejection device 3 widely placed in the entire area of the machine platform 2; a functional liquid supply connected to the droplet ejection device 3 The device 4 ; the head maintenance device 5 installed on the machine platform 2 , so as to be arranged in the droplet ejection device 3 . In addition, in the drawing device 1, the liquid droplet ejection device 3 receives the supply of the functional liquid from the functional liquid supply device 4 under the control of the control device provided outside the figure, and the liquid droplet ejection device 3 executes the process of spraying the workpiece W. drawing operation, and the head maintenance device 5 properly performs the maintenance operation (maintenance) on the functional liquid drop discharge head 21.

[0063] The droplet ejection device 3 has: a moving mechanism 12 com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com