Vacuum solar transduction heat pipe structured in all glass body case and manufacturing method

A production method and all-glass technology, applied in the field of solar energy applications, can solve the problems of low yield, low efficiency, and easy breakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

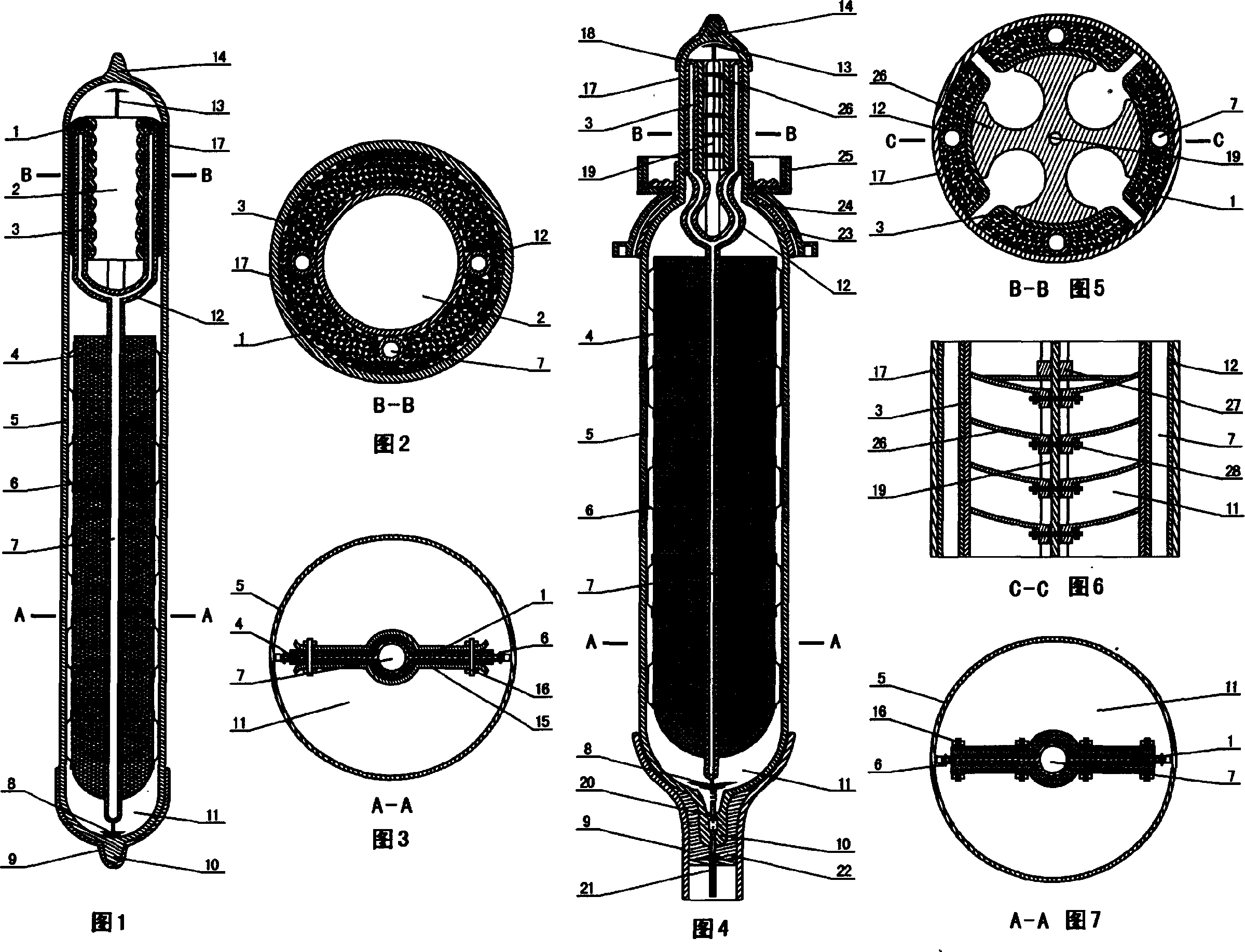

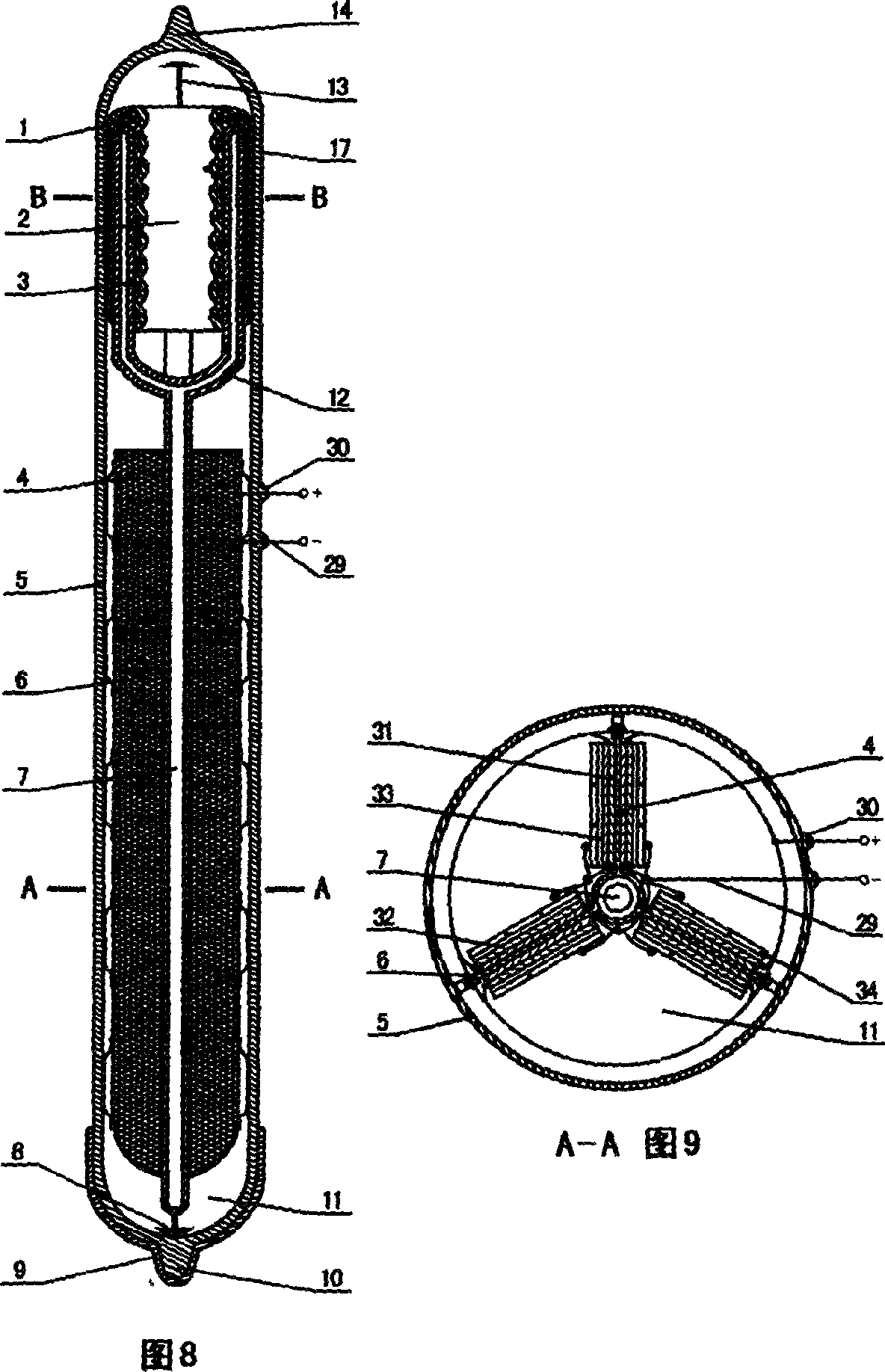

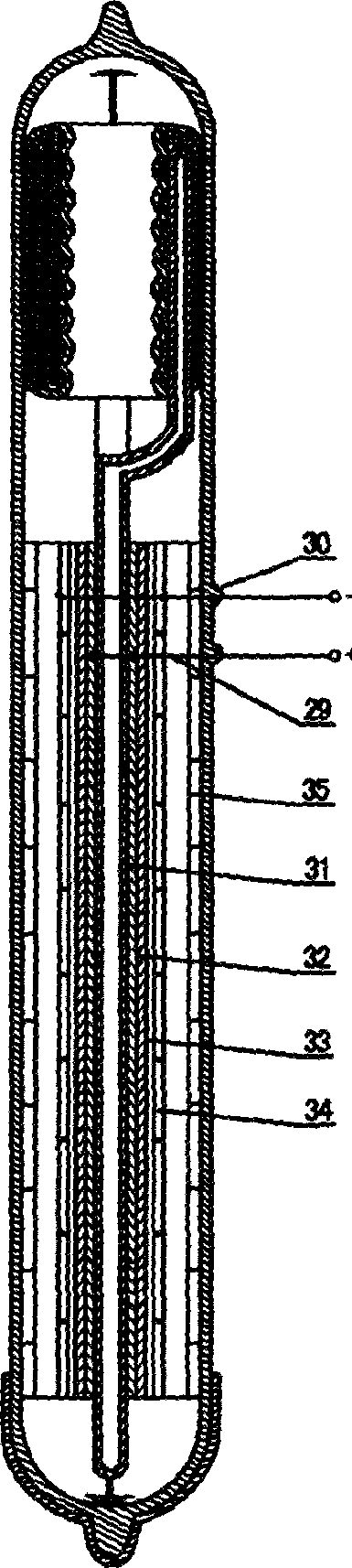

[0111] Fig. 1, Fig. 2, Fig. 3 make up the first embodiment: the shell all-glass vacuum solar heat exchange heat pipe mainly includes two parts, one part is an all-glass closed container shell, and the other part is composed of heat pipes and the like. The all-glass tube used in the embodiment is an all-glass shell formed by welding the glass shell 5 of the heat-absorbing section of the glass heat-collecting tube and the glass tube 17 of the heat-emitting section of the glass heat-collecting tube. Heat conduction particle 1, heat release section of heat pipe 2, heat conduction particle heat pipe metal container 3, heat pipe heat absorption plate 4, glass shell of glass heat collection pipe heat absorption section 5, heat pipe support bullet 6, heat pipe cavity 7, heat pipe end protection Cover 8, glass heat collecting tube heat-absorbing section protective cap 9, glass heat collecting tube protective cap bonding sealant 10, heat pipe throat pipe wall 12, getter 13 are combined w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com