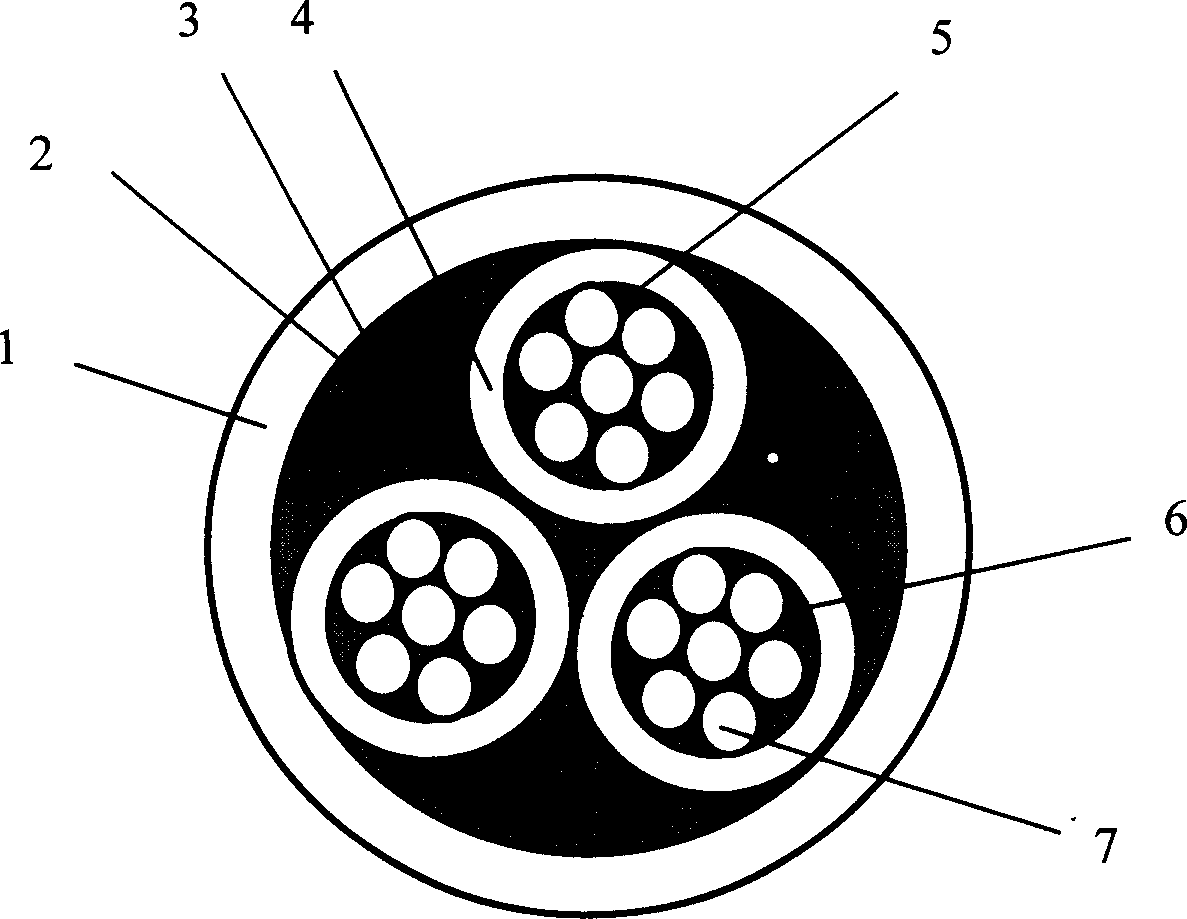

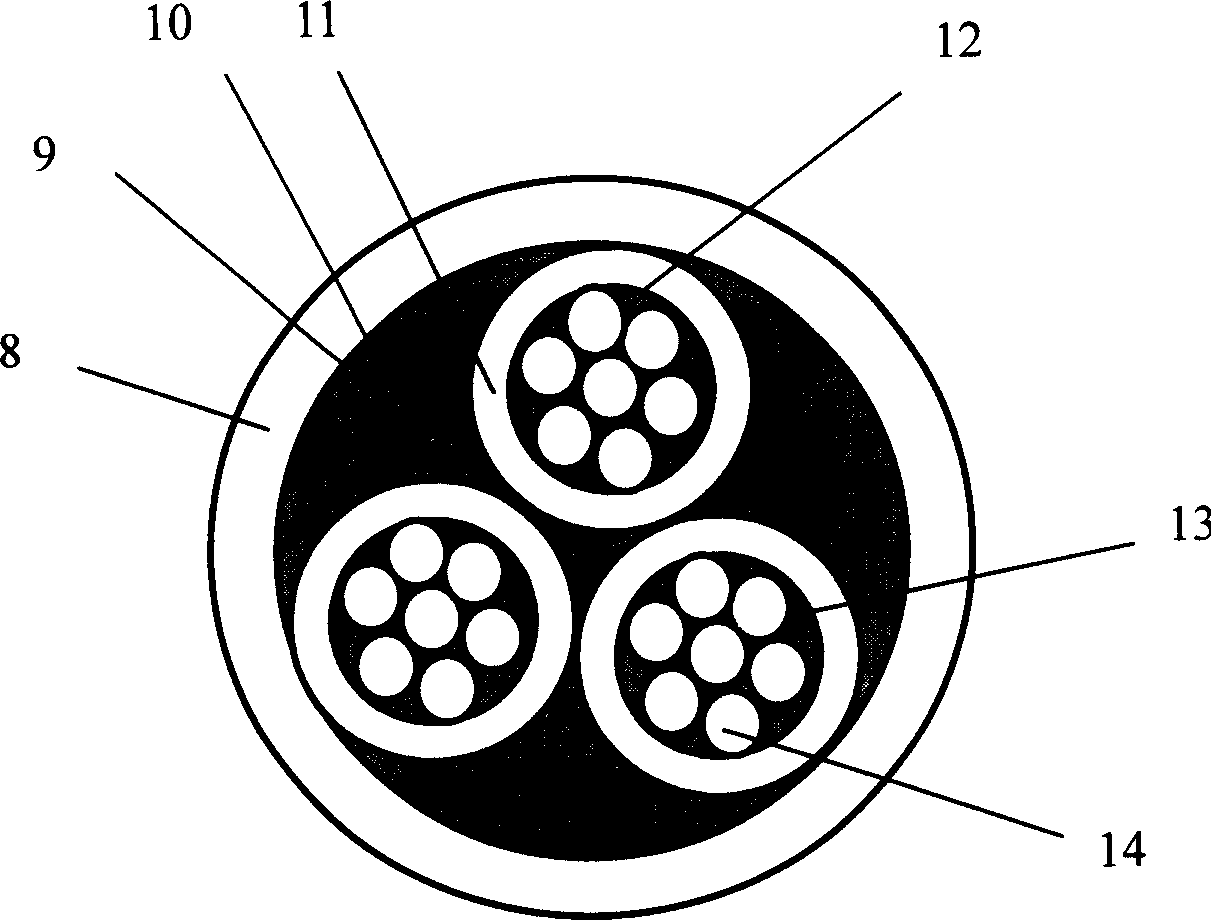

Longitudinal watertightness cable/wire

A water-sealing and cable technology, which is applied to insulated cables, cables, circuits, etc., can solve the problems of low-smoke, halogen-free and longitudinal water-sealing of cables at the same time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0025] First prepare the sealant, select one of them as the main rubber preparation material according to the formulas 1 to 4 in Table 2, and then put the raw material on the two-roller machine, after masticating, after wrapping and rolling, add other components in batches except the vulcanizing agent Divide, mix evenly, remove and pack, and store at room temperature for 48 hours; then put it on a two-roller machine for mixing, after 5 times of thinning, add vulcanizing agent evenly, and cut the material for later use.

[0026] Preface

No

match

party

1

match

party

2

match

party

3

match

party

4

match

party

5

1

Main glue

heat vulcanized silicone rubber

100

100

2

Polyacrylate

100

3

100

4

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com