Electronic parts installation device

A technology for electronic component installation and electronic components, applied in the direction of electrical components, electrical components, etc., can solve problems such as insufficient efficiency of installation operations, and achieve the effect of further increasing efficiency and saving space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] --Overall structure of the embodiment--

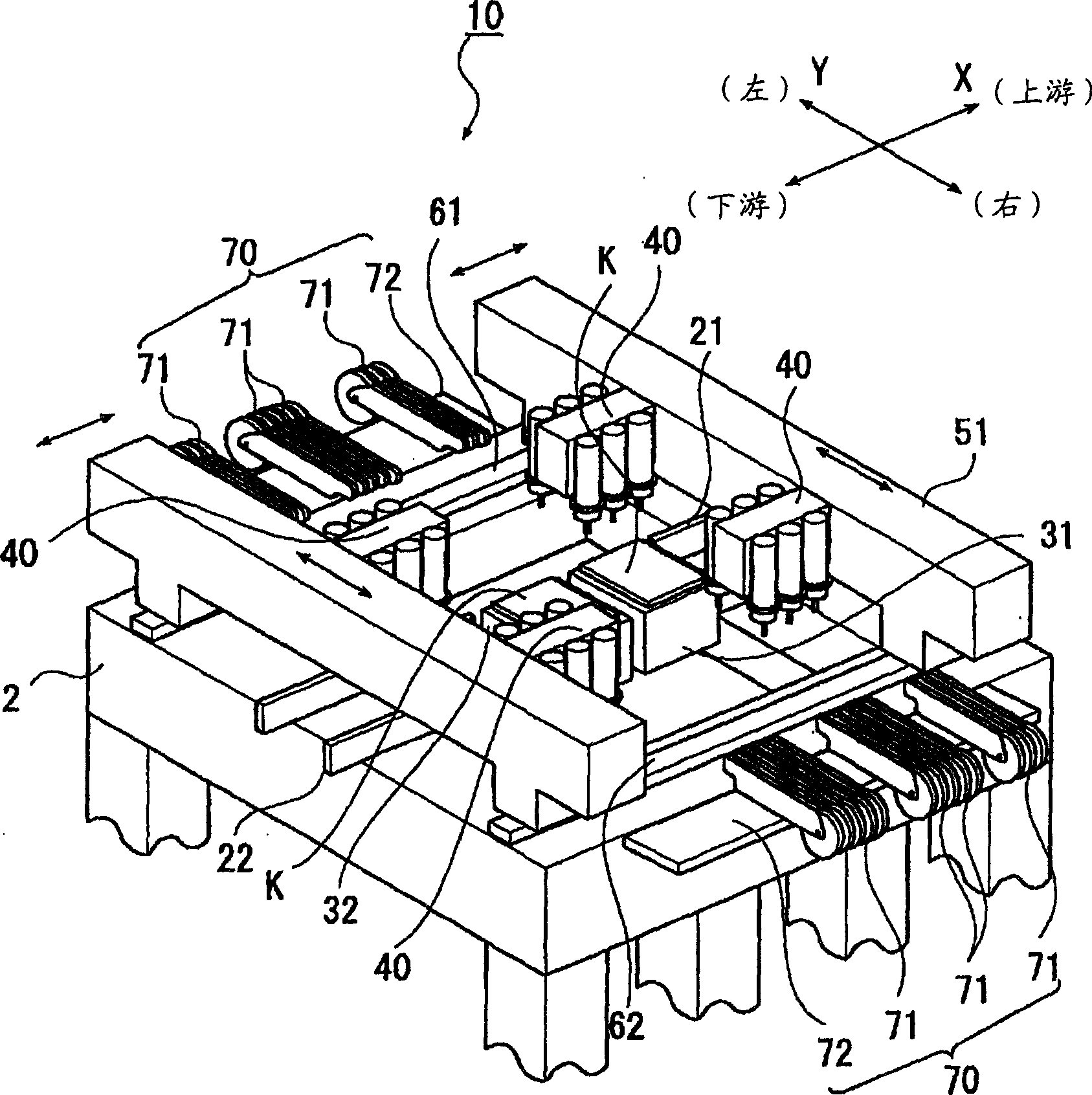

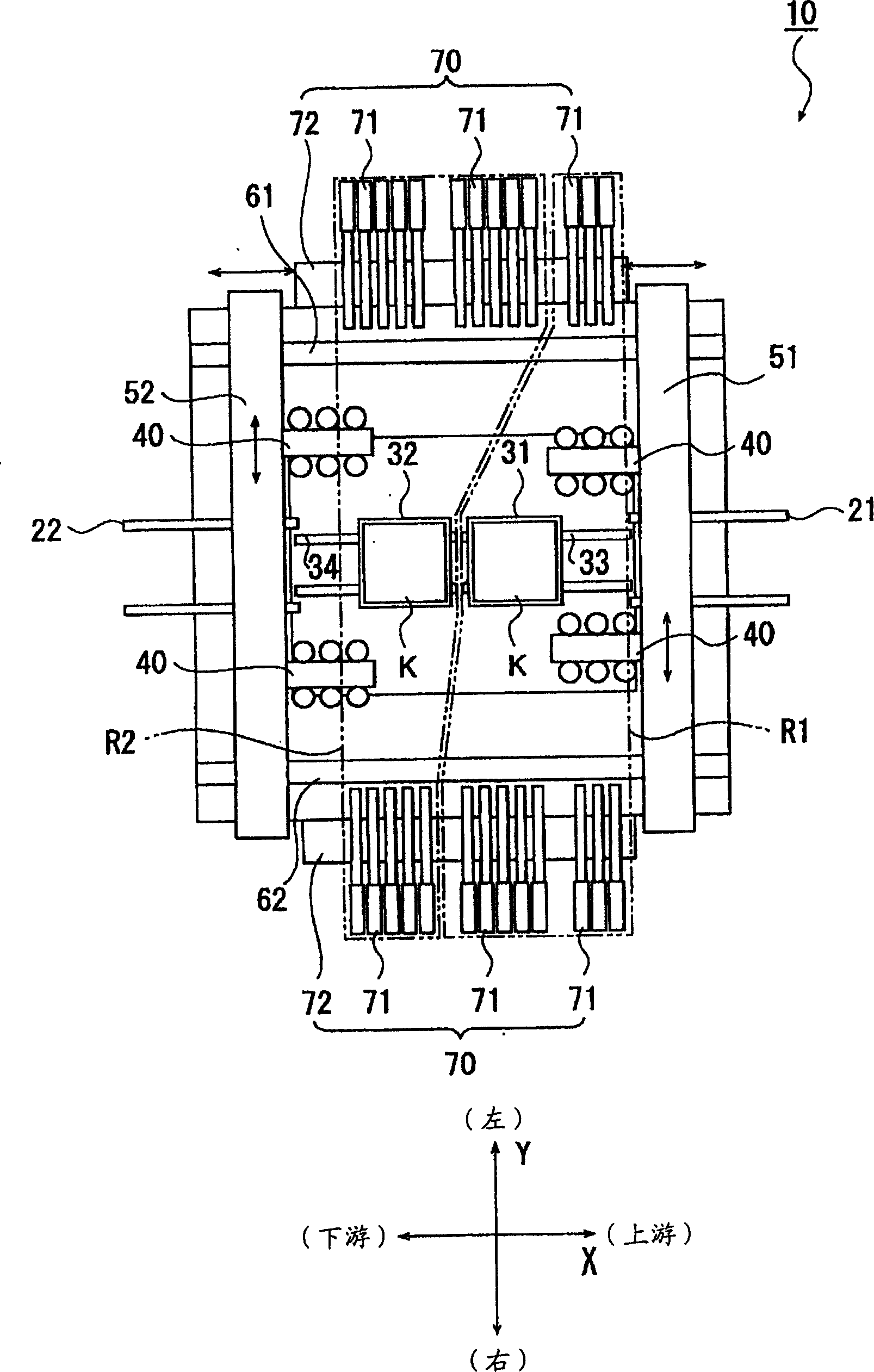

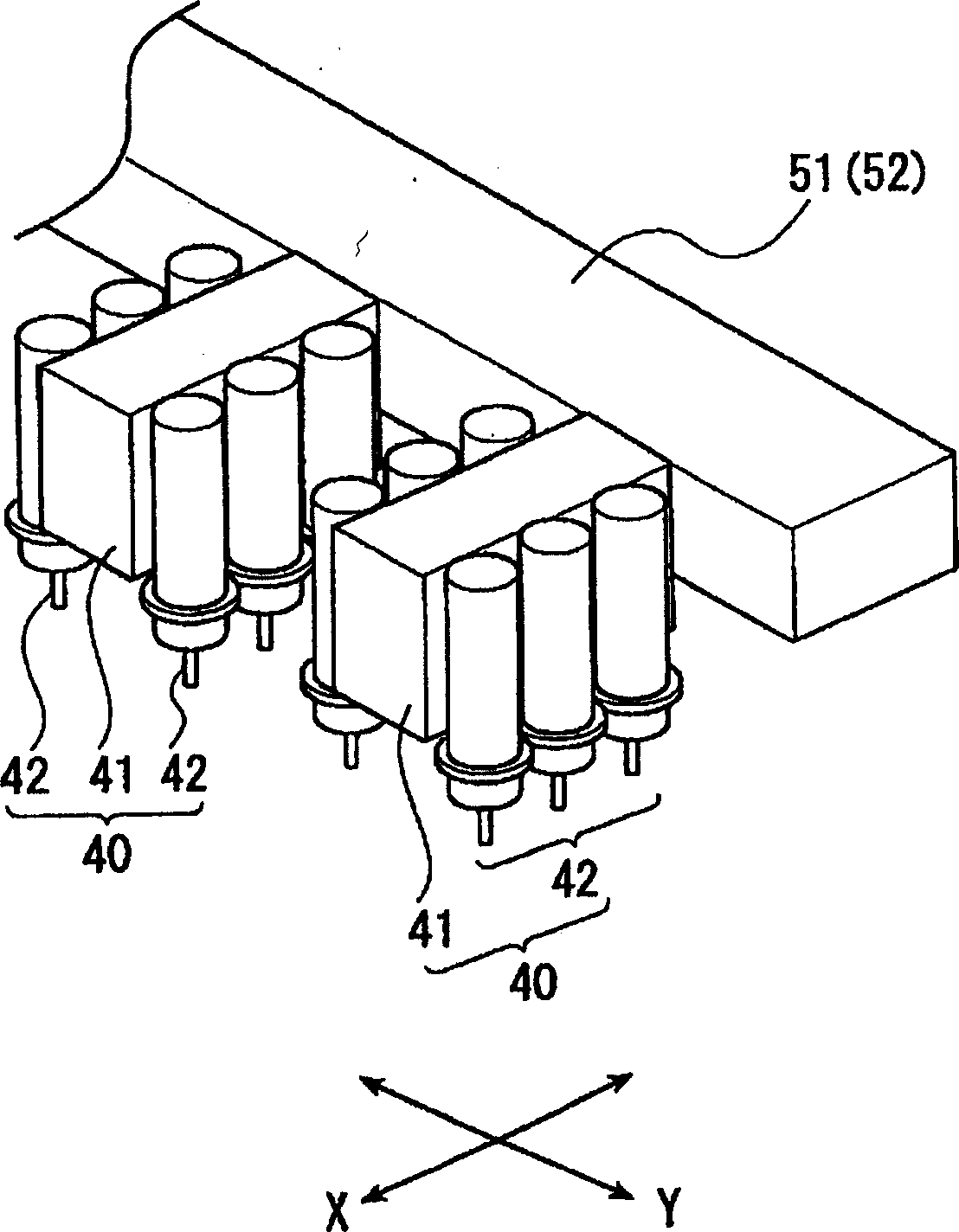

[0037] Below, according to Figure 1 to Figure 5 The electronic component mounting apparatus 10 according to the embodiment of the present invention will be described. figure 1 is a perspective view of the electronic component mounting apparatus 10, figure 2 Indicates a top view.

[0038] In addition, the electronic component mounting apparatus 10 is an apparatus that transports the board K in the transport direction, fixes it at a predetermined position on the board transport path, and mounts electronic components on the board K.

[0039] In the following description, the conveying direction of the substrate K is defined as the X-axis direction, and the direction approximately perpendicular to the conveying direction of the substrate K is defined as the Y-axis direction (see Figure 1 to Figure 5 ).

[0040] Electronic component mounting device 10 such as figure 1 and figure 2 As shown, it has: a rectangular frame-shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com