Sand setting and collecting apparatus

A technology for collecting equipment and sand settling, which is applied to the feeding/discharging device of the settling tank, etc., can solve the problems of high operation cost, high maintenance cost, uneven sand settling, etc., and achieves simple and reliable operation, low maintenance cost, The effect of simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

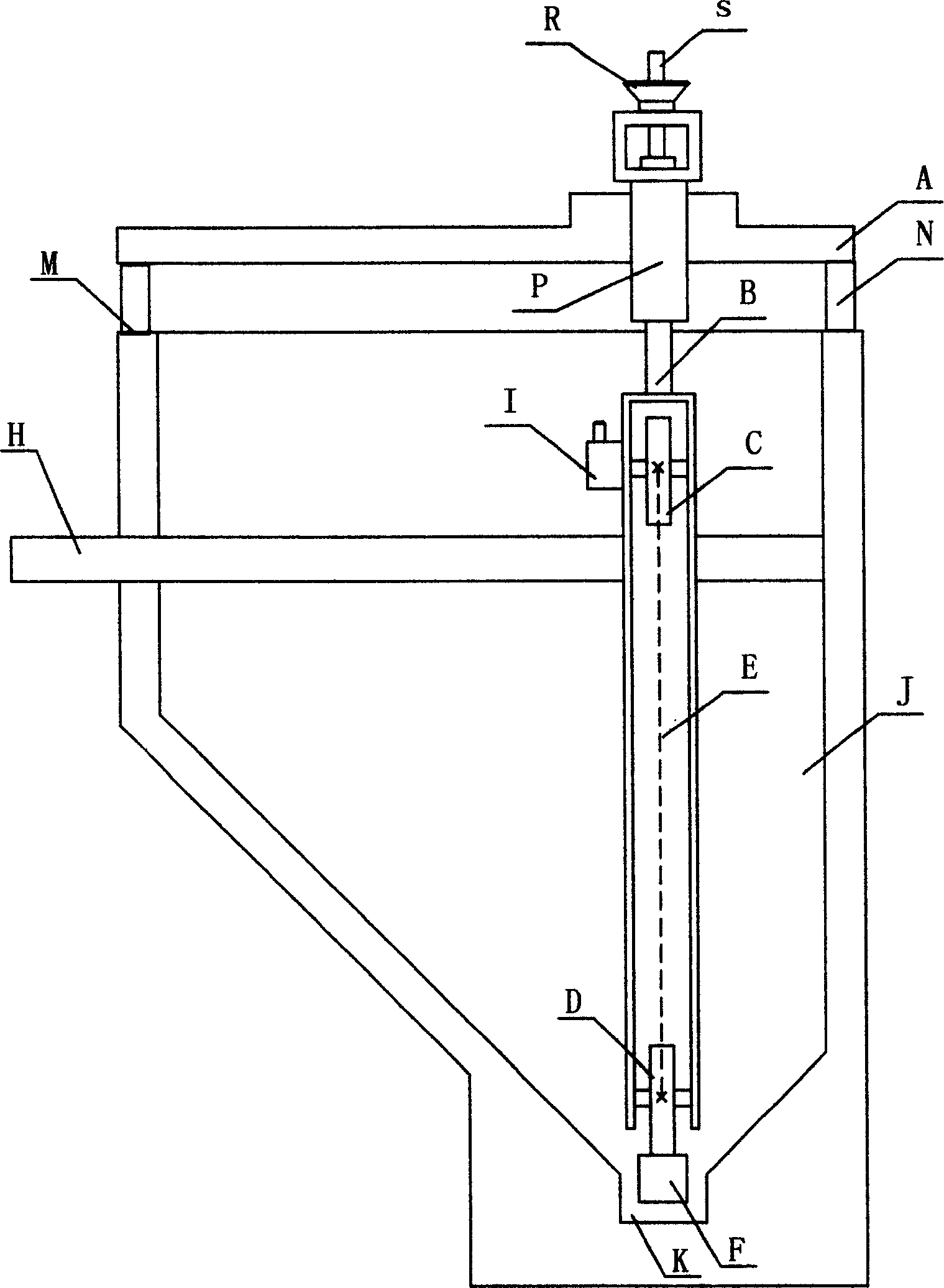

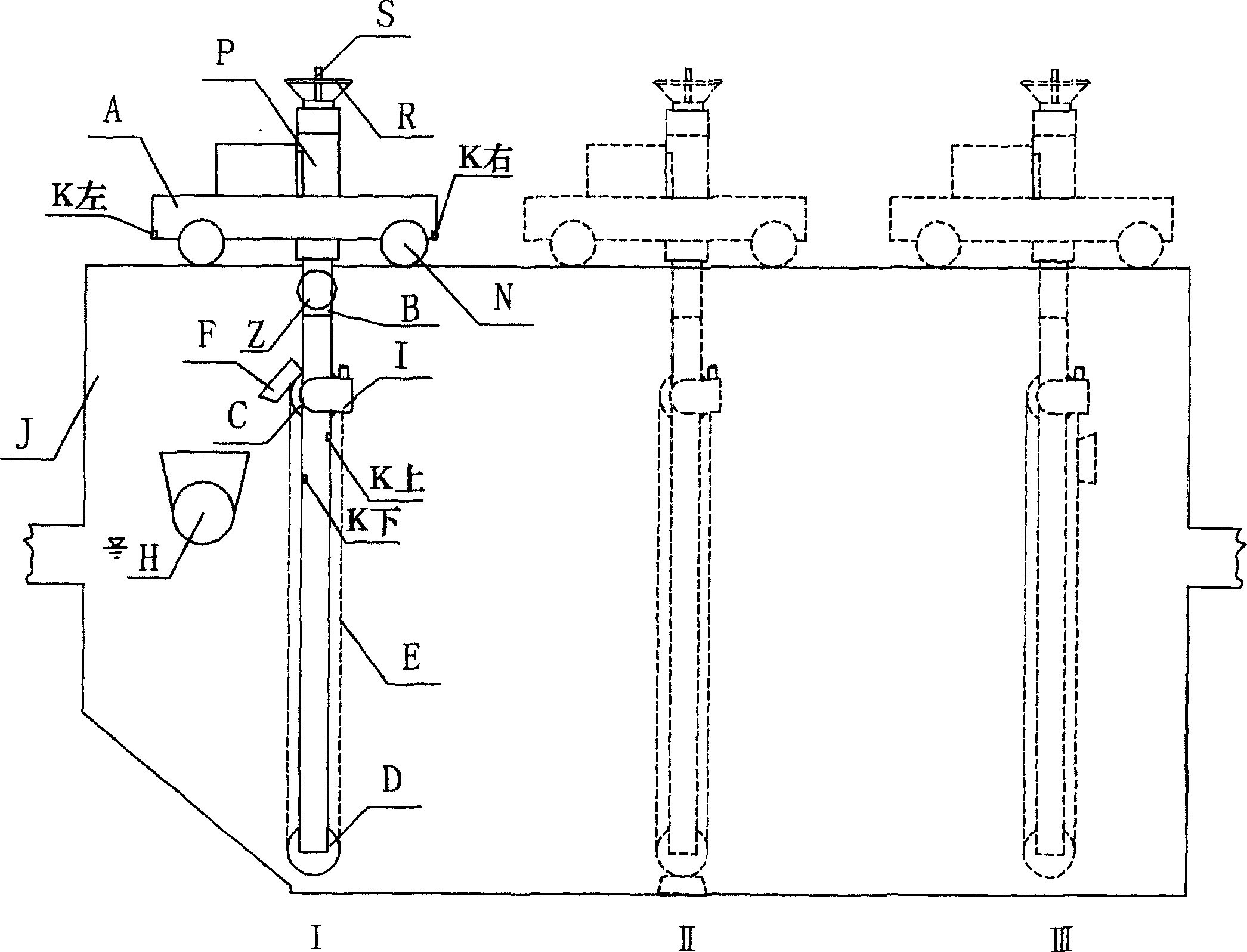

[0012] The structure of the present invention is as figure 1 , 2 As shown, it includes a truss car A with wheels N on the bottom of the truss car A, which can straddle the banks of the aerated grit chamber J, and the wheels n can move along the guide rails M laid on both banks; The scum equipment can scrape the scum in the pool J into the scum tank when the girder truck A is walking along the pool. Scum scraping is an existing mature technology, and will not be repeated here.

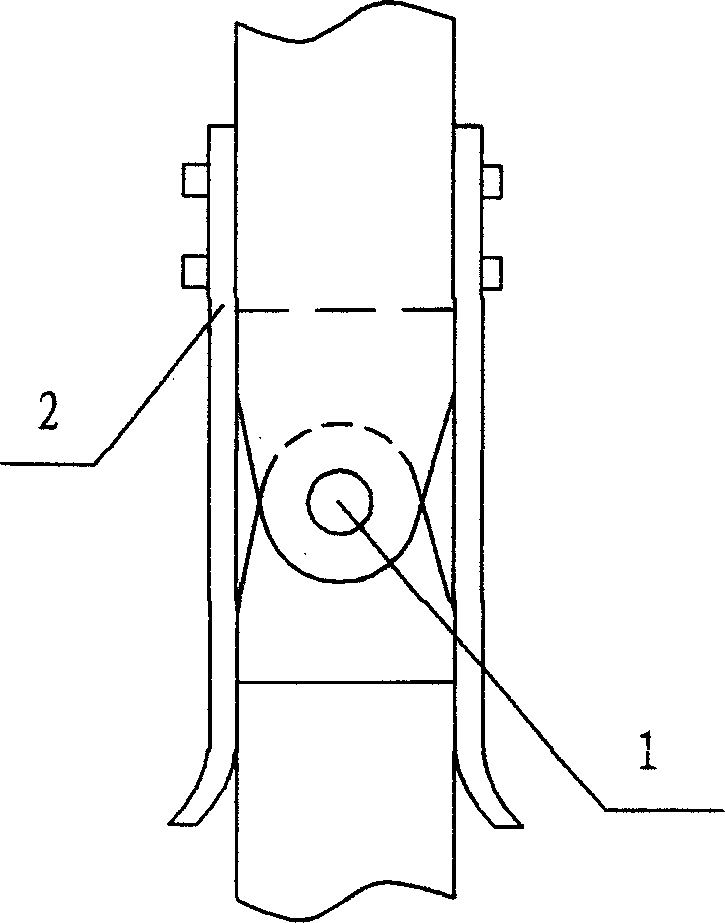

[0013] A bracket P is installed on the truss truck A, and a connecting rod B is installed under the bracket P. The upper part of the connecting rod B has a thread S, which matches the nut handwheel R on the bracket P to form a screw mechanism. The top of the connecting rod B has a Nut handwheel R, rotating nut handwheel R and connecting rod B will go up and down. The upper part of the connecting rod B is installed with the motor I and the upper sprocket C, and the lower end is installed with the lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com