Pneumatic flexible finger prosthesis

An artificial and finger technology, applied in the field of artificial fingers, can solve the problems of less freedom, narrow working range, and can only complete simple movements, etc., and achieve the effect of strong adaptability and high flexibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

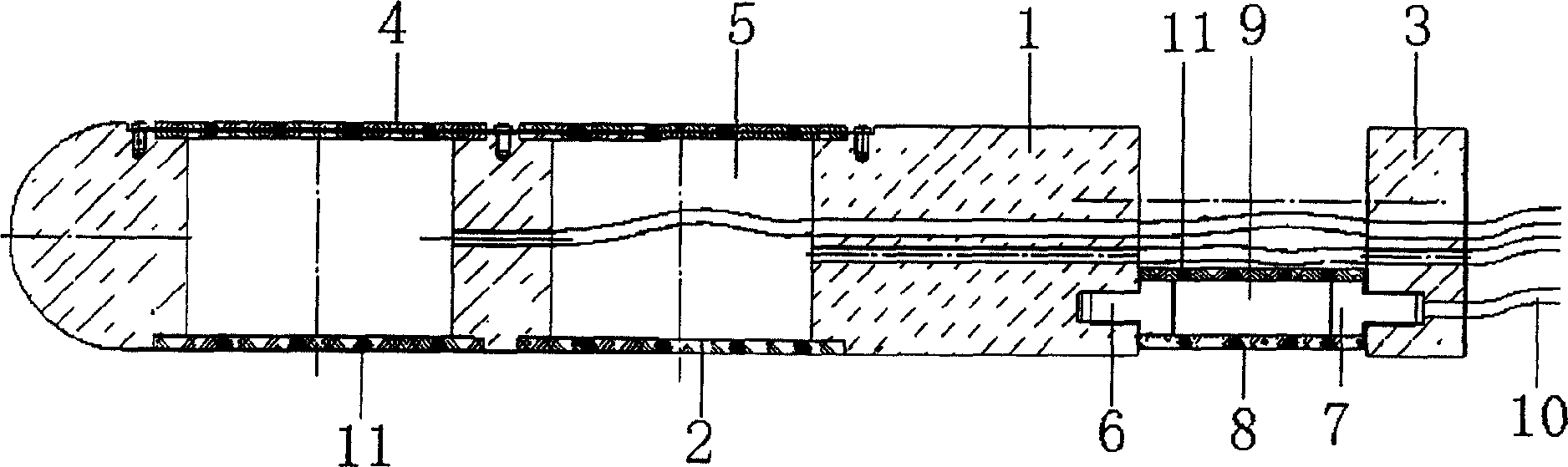

[0014] refer to figure 1 , this embodiment is a five-degree-of-freedom pneumatic flexible artificial finger, which has three rigid bodies 1, two thick rubber tubes 2 and an end cap 3, the thick rubber tubes 2 and rigid bodies 1 are arranged alternately in sequence, and the two ends of the thick rubber tubes 2 pass through The superglue is tightly connected with the rigid body 1. A side wall of the thick rubber tube 2 is provided with a restraint steel wire 4, and the restraint steel wire 4 in each thick rubber tube 2 is located on the same side, and the restraint steel wire 4 can be fixed on the rigid body 1 by screws. The sealed space formed by each thick rubber tube 2 and the rigid body 1 forms a working chamber 5 . The end face of the rigid body at the end is evenly equipped with three first joints 6 (only one is drawn in the figure), and the end face of the end cover 3 is evenly equipped with three second joints 7 (only one is drawn in the figure). The two ends of the pi...

Embodiment 2

[0018] refer to figure 1 A helical wire 11 is nested in the wall of the thick rubber tube 2 , and the restraining steel wire 4 is wound with each turn of the helical wire 11 . A helical wire is embedded in the wall of the thin rubber tube. When the compressed gas is fed into the working chamber 5, the spiral wire 11 can limit the radial expansion of the thick rubber tube wall and avoid the radial deformation of the fingers. The tube wall of the thin rubber tube 8 is also nested with a helical wire 11, so that the thin rubber tube 8 has a certain rigidity, and avoids difficulty in controlling the thin rubber tube 8 because it is too soft.

Embodiment 3

[0020] This embodiment is a four-degree-of-freedom pneumatic flexible artificial finger, which has two rigid bodies, a thick rubber tube and an end cap. The thick rubber tube and the rigid body are arranged alternately in sequence, and the two ends of the thick rubber tube are sealed and connected to the rigid body by superglue. One side of the thick rubber tube is provided with restraining steel wires, and the restraining steel wires in each thick rubber tube are located on the same side, and the restraining steel wires can be fixed on the rigid body by screws. The sealed space formed by each thick rubber tube and the rigid body constitutes a working chamber. The rigid body at one end has three first joints evenly installed on its end surface, and three second joints are evenly installed on the end surface of the end cover. The two ends of the three thin rubber tubes are respectively sealed with the respective first and second joints by superglue connect. The sealed space fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com