Components of artificial marble and process for making same

A technology for artificial marble and components, applied in the field of artificial marble components and manufacturing processes, can solve the problems of filler limitation and high cost, and achieve the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

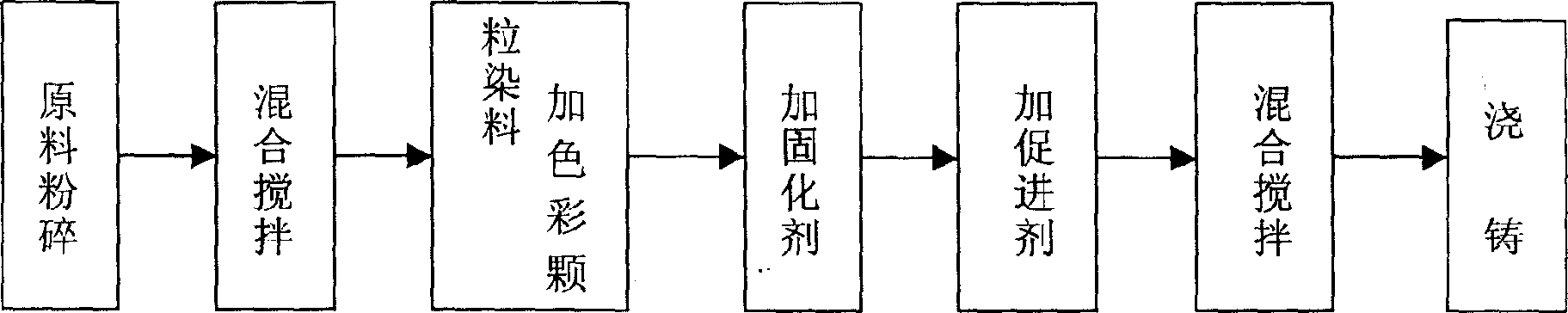

Image

Examples

Embodiment Construction

[0018] The composition of artificial marble is composed of filler and binder. The filler of artificial marble is waste glass, and the binder of artificial marble is unsaturated polyester. Its composition is waste glass of filler and unsaturated polyester binder. The weight ratio is 3~5:1;

[0019] The particles of waste glass are 20-60 mesh, and the amount of filler waste glass is determined by the size of the particles. When the particle size of waste glass is 20 mesh, its composition is the weight of filler waste glass and binder unsaturated polyester. The ratio is 3:1, the hardness of marble is low, but the toughness is good, and the curing time is long. When the particle of waste glass is 60 mesh, its composition is filler. The weight ratio of waste glass to binder unsaturated polyester is 5:1 , its marble has high hardness, but poor toughness and short curing time.

[0020] Please refer to Figure 1 artificial marble manufacturing process, the artificial marble manufactur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com