Skirt guided globe valve

A valve plug and valve stem technology, applied in the field of skirt-guided spherical valves, can solve problems such as hydrodynamic resistance and maximum flow drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Skirt guided ball valves have been used in the process control industry for decades. While skirt pilot valves have many advantages, they also have serious drawbacks. One drawback is the reduced flow compared to other types of valves because in skirt pilot valves a portion of the plug can never be fully retracted off the seat. The two-way skirt-guided ball valve disclosed herein has increased flow as a result of surface topography and mixing edges in the valve to achieve a streamlined, laminar flow while maintaining the same Pilot valves are usually associated with efficiency and reliability.

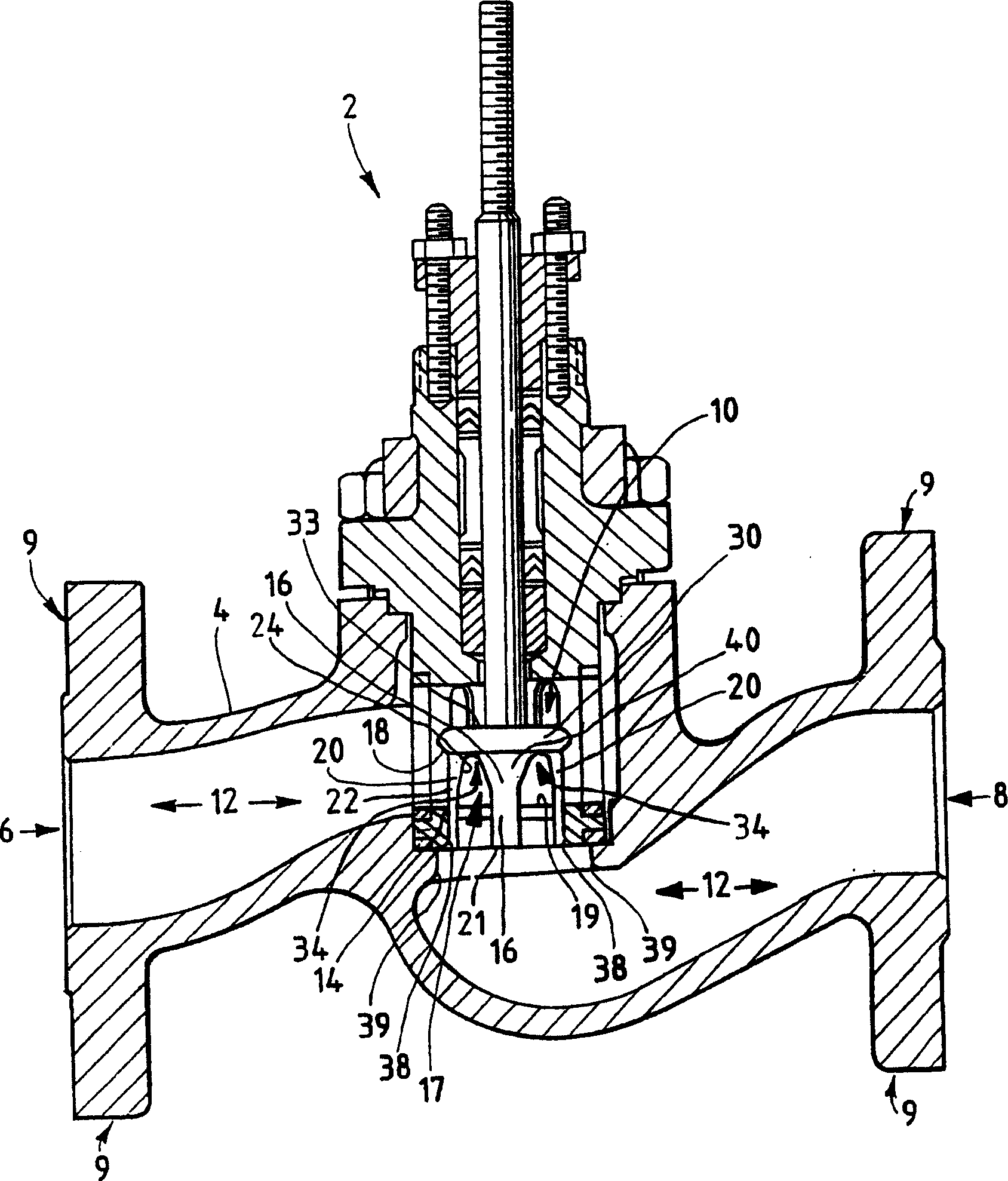

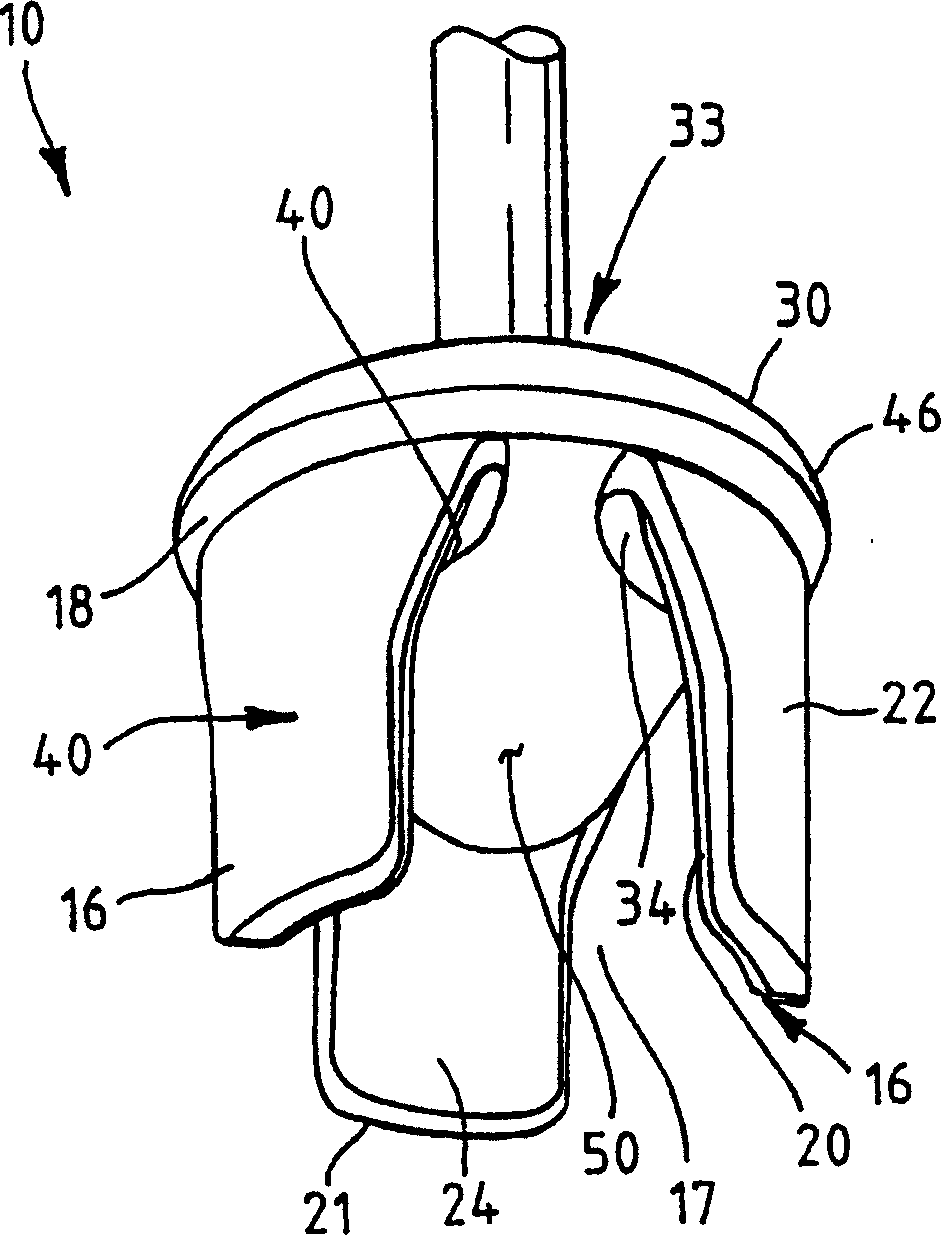

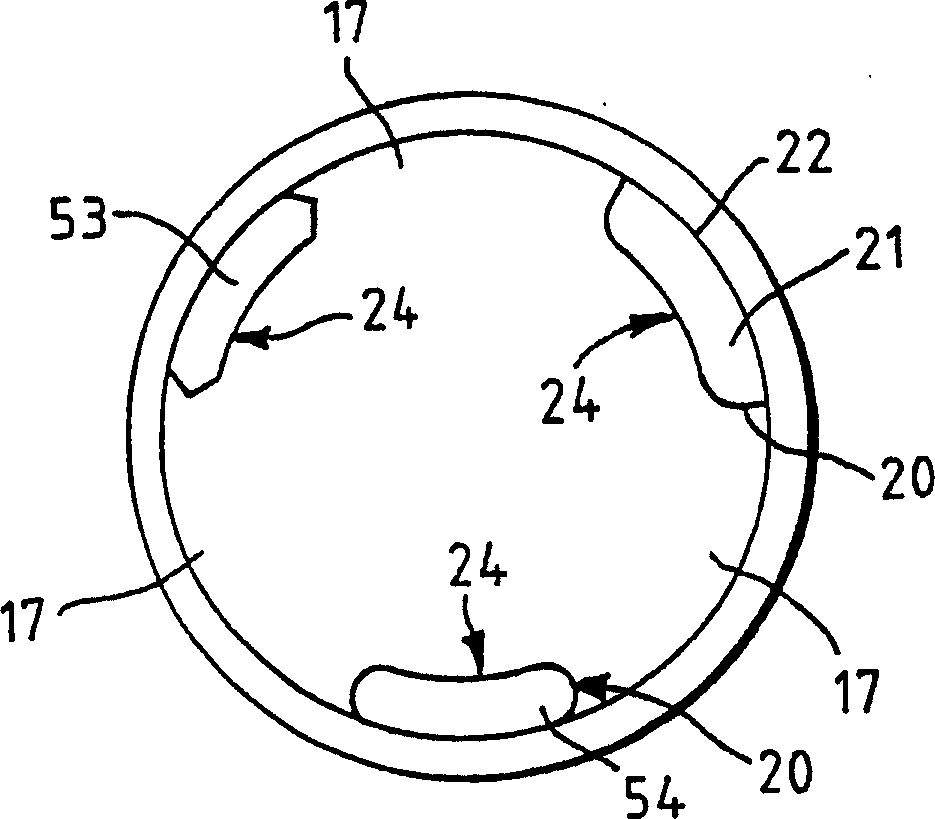

[0017] figure 1 A skirt piloted ball valve 2 is shown having a valve body 4, an outlet 6, an inlet 8 (when used in an up-flow configuration) and a skirt plug 10 (in figure 2 in more detail). The outlet 6 and the inlet 8 generally have a mounting mechanism such as a flange 9 to install the ball valve 2 into the process system. The outlet 6 and the inlet 8 are connected by a f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com