Electrostatic capacity type liquid sensor

一种液体传感器、静电电容的技术,应用在仪器、测绘与导航、测量装置等方向,能够解决很难长期确保传感器稳定性和可靠性等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

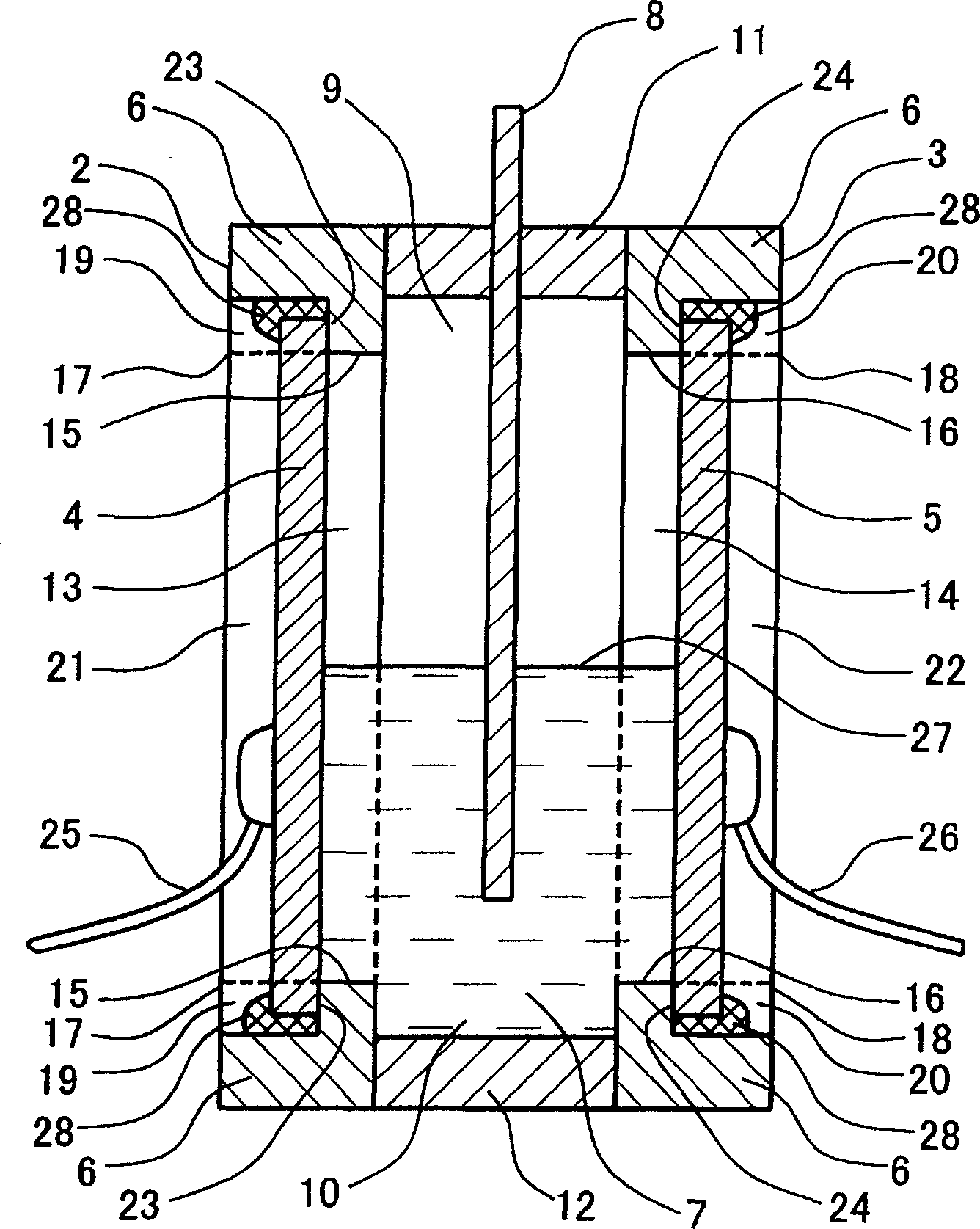

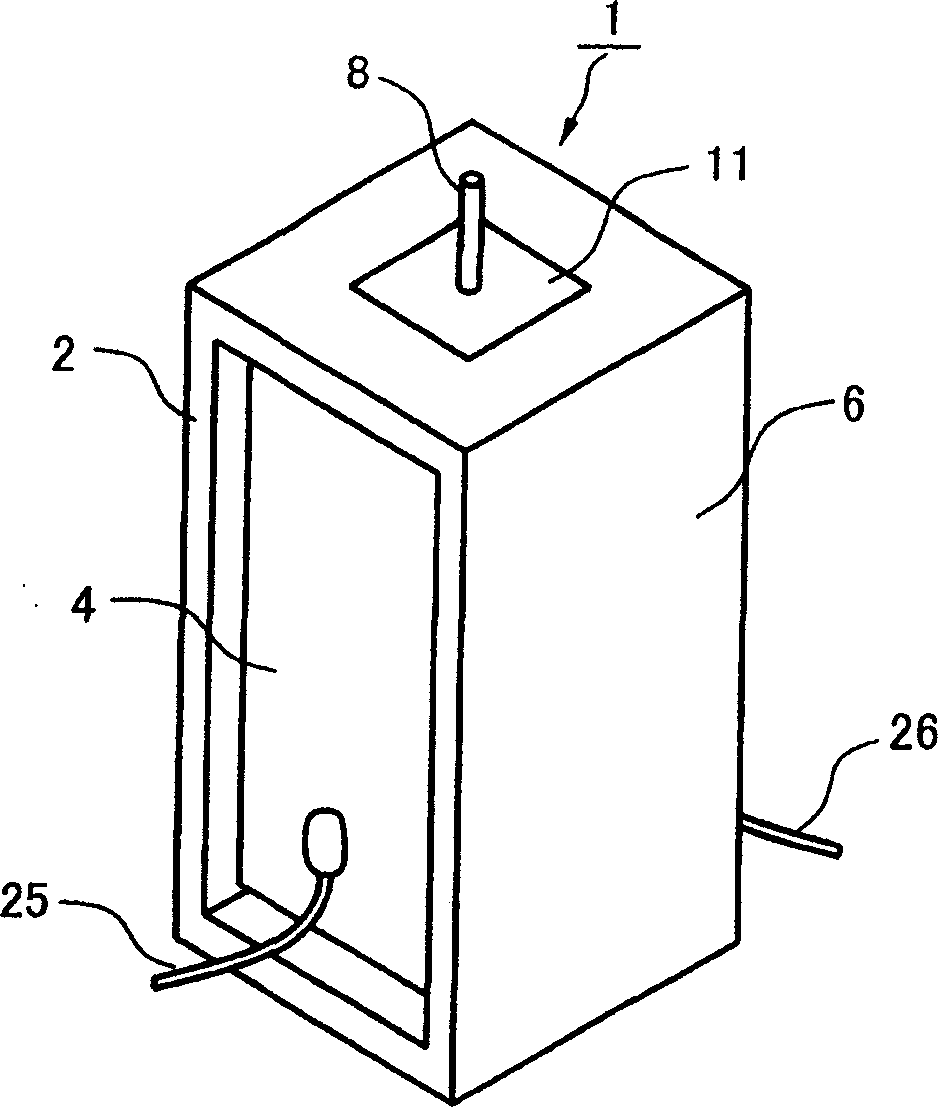

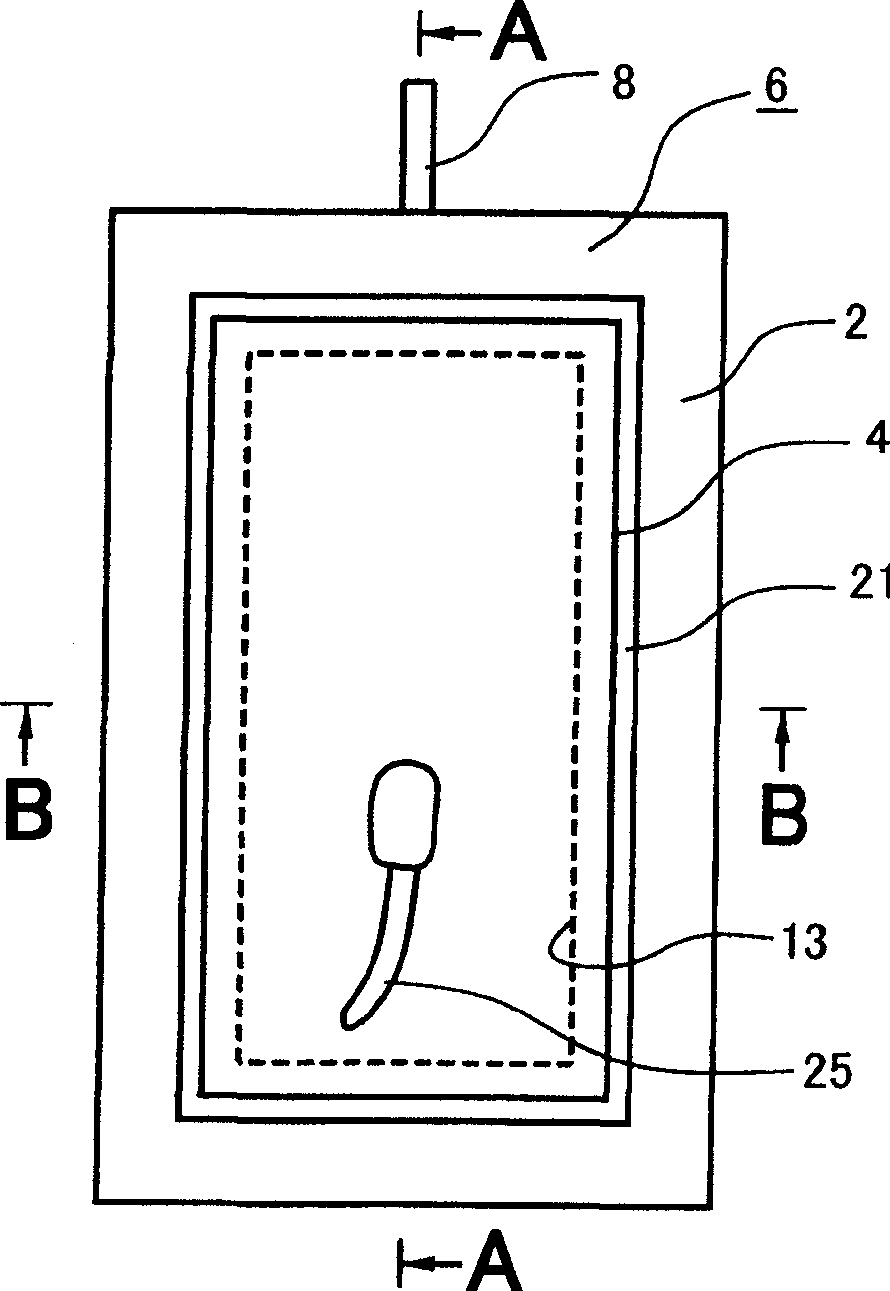

[0039] A first embodiment of the present invention will be described with reference to the drawings. figure 2 A perspective view showing the appearance of the liquid sensor of this embodiment, image 3 is shown in front view, figure 1 Shown in its longitudinal section (A-A section), Figure 4 Its cross-sectional view (B-B section) is shown in .

[0040] The structure of the liquid sensor 1 of this embodiment is that openings 13, 14 are provided on the two parallel sides 2, 3 of the cylindrical container 6 closed at both ends, and the embedded surface in the openings 13, 14 is covered with a silicon oxide coating. The plate-shaped main electrodes 4 and 5 of the film are sealed, and an appropriate amount of conductive liquid 7 is sealed inside, and the metal sub-electrode rod 8 is inserted into the conductive liquid 7 from the upper cover 11 .

[0041] The cylindrical container 6 is a cylindrical container having two parallel sides 2 , 3 . The cross section does not have to ...

no. 2 example

[0064] Since the liquid sensor in the first embodiment has a pair of main electrodes, it can only measure an inclination angle or acceleration along a line perpendicular to the surface of the main electrodes. Regarding this point, the liquid sensor of the second embodiment is a liquid sensor configured to be able to measure inclination angles or accelerations in two directions perpendicular to the horizontal plane. Figure 8 A perspective view showing the appearance of the liquid sensor 1a of this embodiment, Figure 9 shows its cross-section. Since the liquid sensor 1a has many structural parts that are the same as the liquid sensor 1 of the first embodiment, the parts that are the same as or correspond to the liquid sensor 1 are assigned the same symbols.

[0065] In the liquid sensor 1a of this embodiment, the cylindrical container 6 is formed in a square cylindrical shape. In addition, it is structured such that four plate-shaped main electrodes 4, 5, 4a, 5a having a sil...

no. 3 example

[0073] Next, a third embodiment of the liquid sensor of the present invention will be described with reference to the drawings. Figure 11 12 is a longitudinal sectional view of the liquid sensor of this embodiment, and FIG. 12 is a perspective view showing the arrangement of electrodes inside the sensor.

[0074] The liquid sensor 40 of this embodiment is a liquid sensor with a pair of main electrodes, consisting of a container 41, a conductive liquid 42, a disc 43, first and second lead terminals 44, 45, and first and second main electrodes 46, 47 poses.

[0075] The container 41 is a substantially cylindrical container with one end sealed, and is formed of a conductive material. As the conductive material, a metal with strong corrosion resistance, such as stainless steel, can be used. The opening of the cylindrical container 41 is closed with a disc 43 to form a sealed structure as a whole. The circular plate 43 is also formed of a conductive material.

[0076] In the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com