Controllable guided air supply system for drying houses

A technology of air supply system and drying room, which is applied in the direction of drying gas arrangement, drying, drying machine, etc. It can solve the problems of prolonging the drying cycle, increasing the pressure head of the fan, and increasing the power consumption, so as to improve the drying efficiency and improve the drying efficiency. The effect of air supply flow rate and reduction of air supply resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

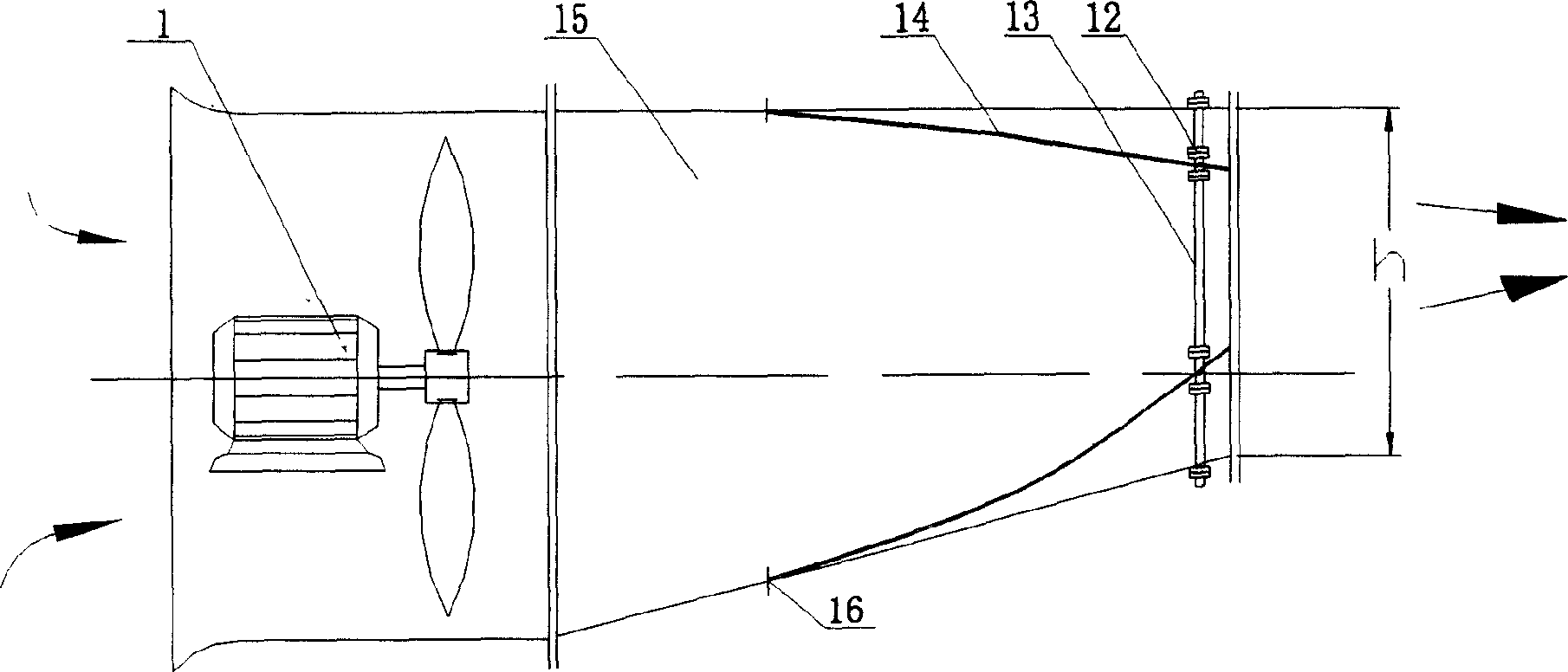

[0013] Depend on Figure 2-Figure 4 As shown, a controllable guided air supply system for a hot air drying room, which includes a fan, is characterized in that a guided air supply device 10 is placed at the air outlet of the fan 1, and the guided air supply device has a round-to-rectangular shape The variable-diameter housing 15 is equipped with 1 or 2 adjustable guide tongues 14, and a guide bend 11 is disposed at the corner of the side wall on the top of the drying room, which cooperates with the guide air blower 10 to form a smooth and controllable flow. Attach airflow. The guide air blower is installed at the air outlet of the high-efficiency environmental protection fan, and is connected with the fan casing by bolts. The shell of the guide air blower is a round-to-rectangular special-shaped variable-diameter shell. The connection between it and the fan is circular, and the air outlet is rectangle.

[0014] Depend on image 3 , Figure 4 As shown, the adjustable deflec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com