A heat exchanger plate, a plate heat exchanger and a method for manufacturing a heat exchanger plate

A technology of plate heat exchanger and heat exchanger, applied in the field of manufacturing heat exchanger plates and plate heat exchangers, can solve problems such as having to be disassembled and replaced.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

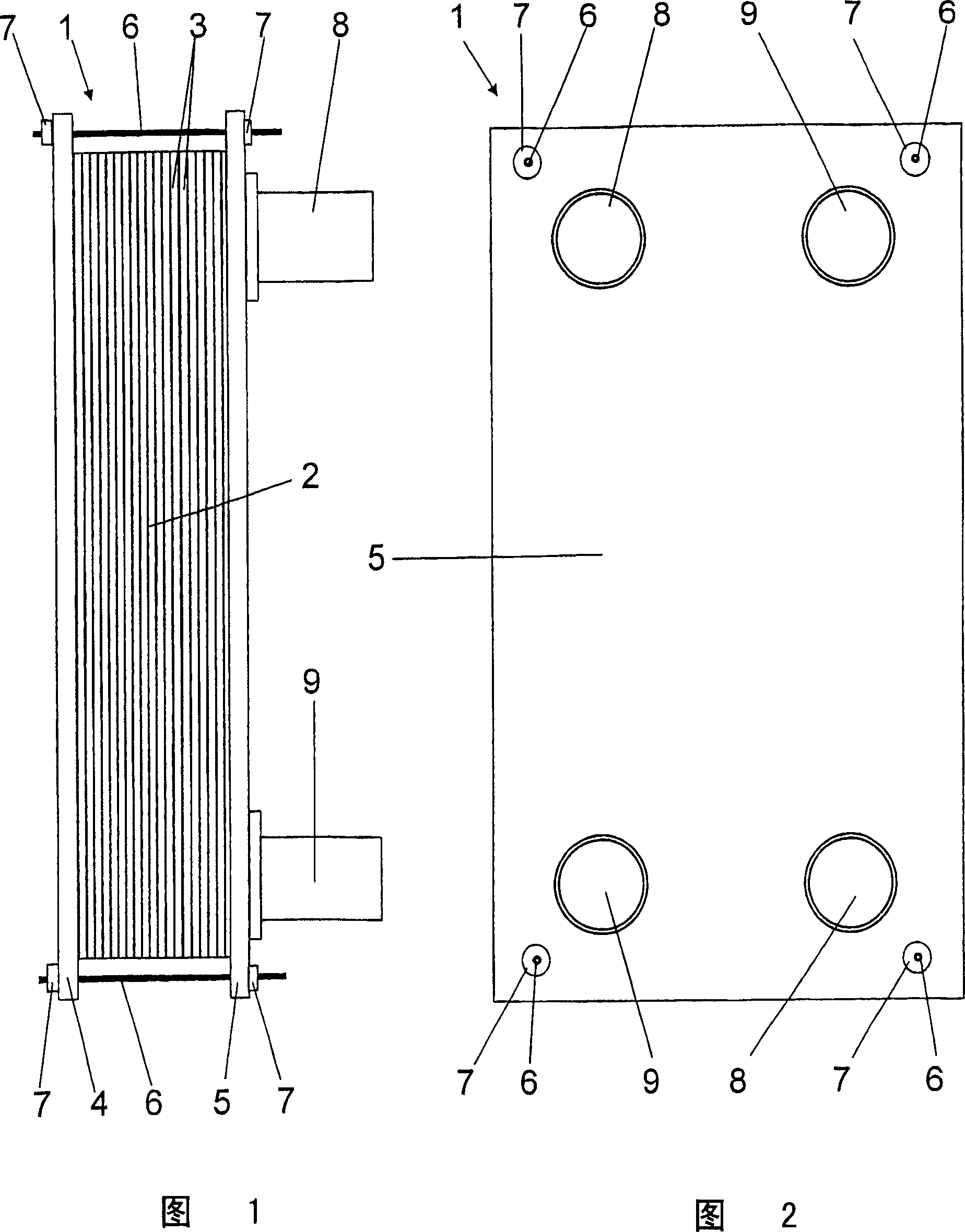

[0027] Figures 1 and 2 show a plate heat exchanger 1 comprising a plate assembly 2 with heat exchanger plates 3 arranged adjacent to each other. This plate assembly is arranged between two end plates 4 and 5 . The end plates 4 and 5 are pressed against the plate assembly 2 and against each other by means of tension bolts 6 which extend through the end plates 4 and 5 . The tension bolt 6 comprises a thread, and thus the plate assembly 2 can be compressed by screwing a nut 7 onto the tension bolt 6 in a manner known in the art. In the illustrated embodiment, four tension bolts 6 are shown. It should be noted that the number of tension bolts may vary and may be different in different applications.

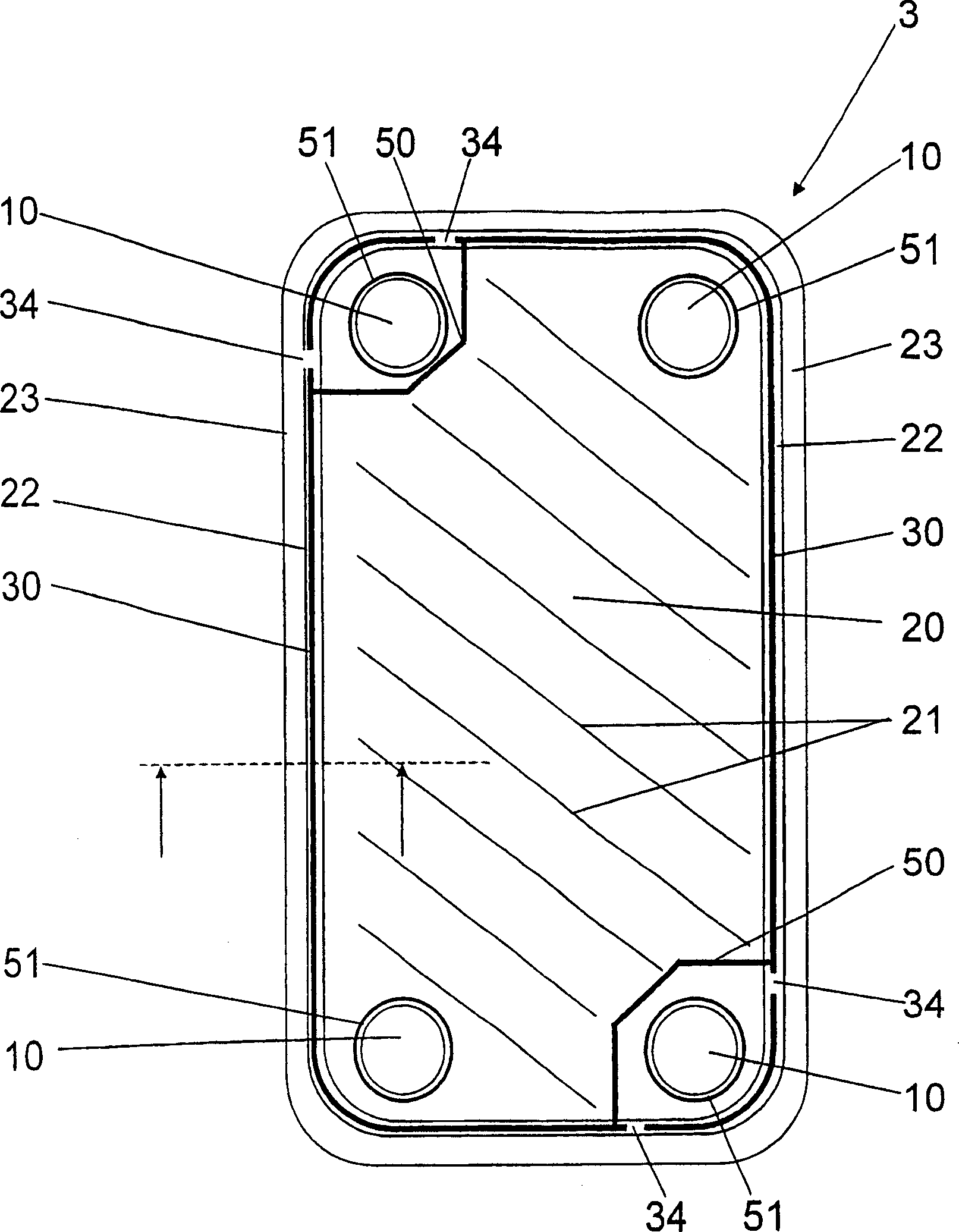

[0028] The plate heat exchanger 1 also comprises two inlet pieces 8 and two outlet pieces 9 . The inlet piece 8 and the outlet piece 9 extend through one of the end plates 5 and the plate assembly 3 . Plate 3 is provided with openings 10 in a manner known in the art, see image 3 ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap