Construction machine

A technology for construction machinery and working machines, which is applied in sewing equipment, sewing machine components, earthmoving machines/shovels, etc., can solve the problems of design, manufacturing work burden, difficult flow of molding materials, and large number of parts, and achieves a reduction in the number of parts. Improved weight, load-resisting strength, and improved mechanical reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

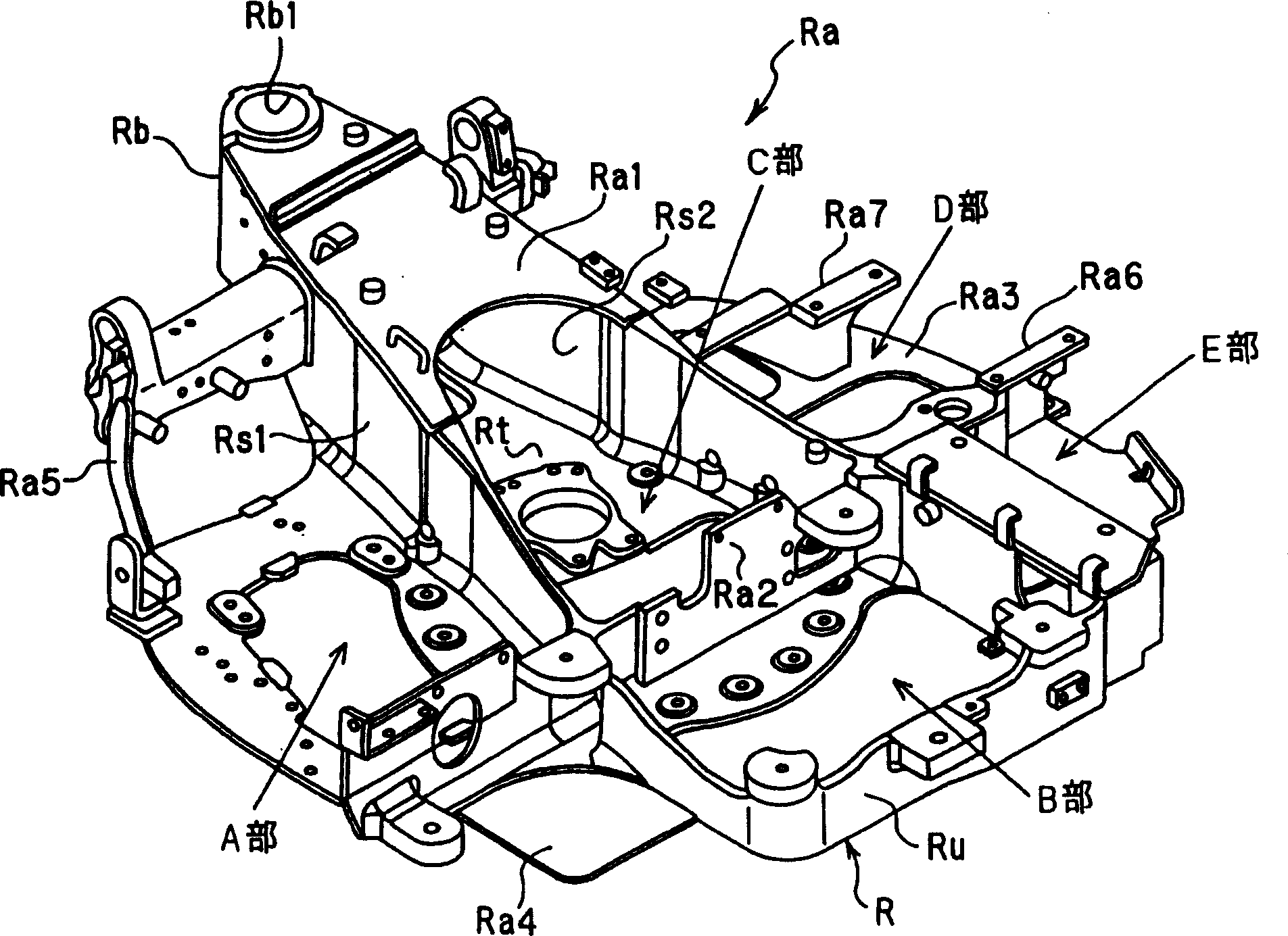

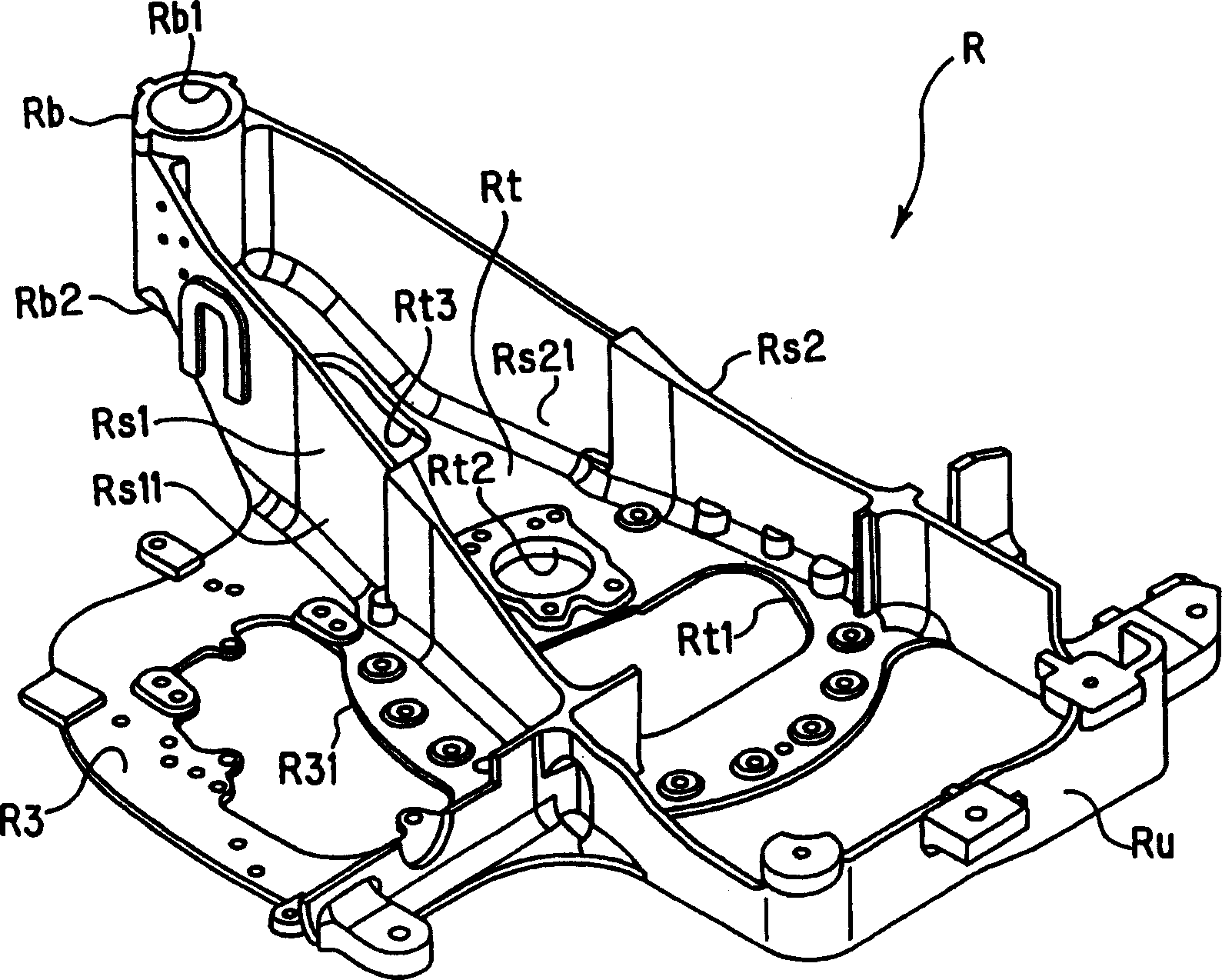

[0030] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

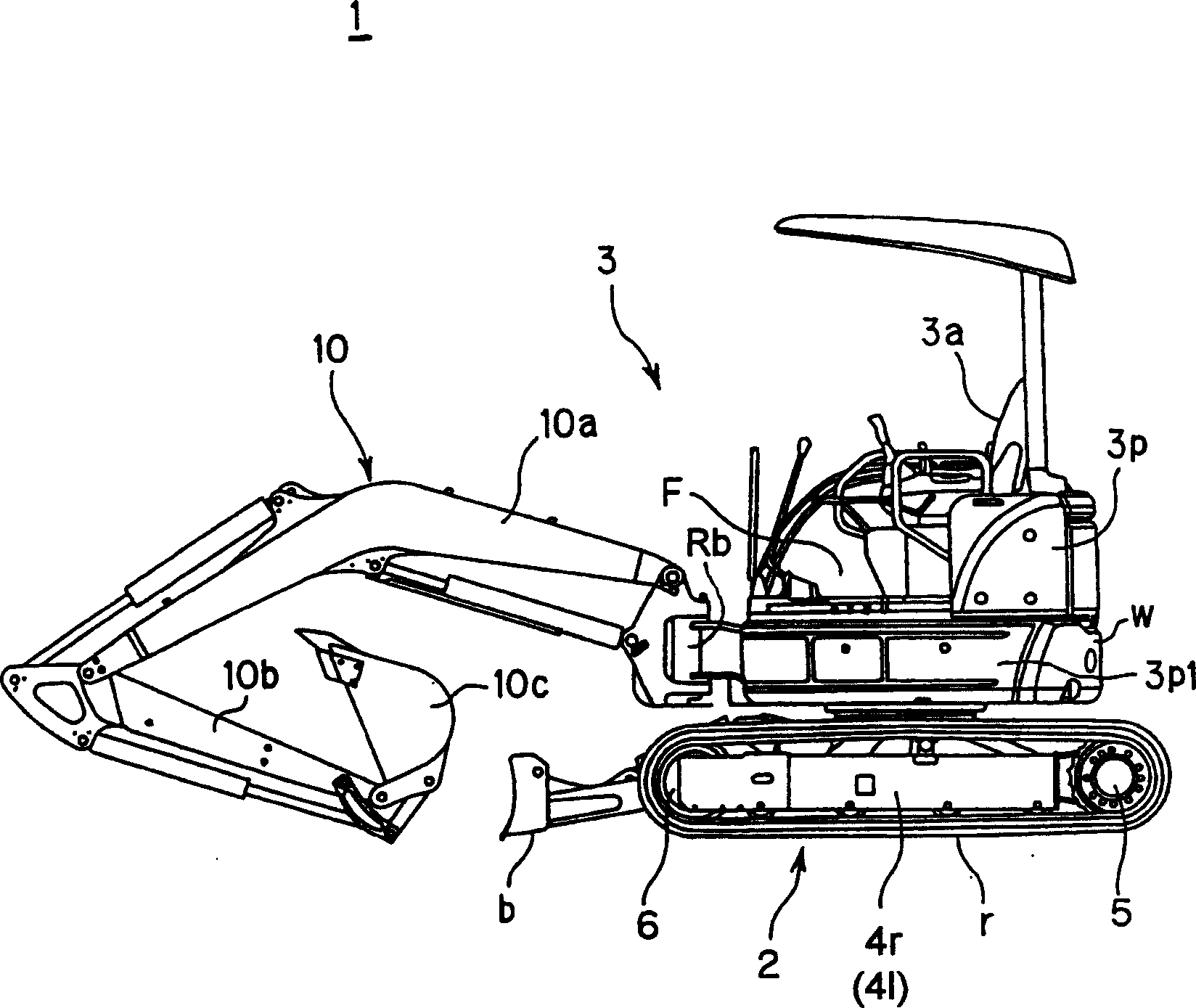

[0031] The hydraulic excavator (engineering machine) 1 of the embodiment of the present invention, as by side view figure 1 As shown in FIG. 1 , it includes an undercarriage 2 provided with crawler belts r for movement, and a revolving upper body 3 rotatably mounted on the upper part thereof for an operator to sit on and perform work.

[0032] The undercarriage 2 has drive wheels 5 and floating wheels 6 attached to both ends of the track frames 4 r and 41 , respectively, and the crawler belt r is wound between the driving wheels 5 and the floating wheels 6 .

[0033] Further, a dozer blade b used for backfilling soil excavated by the bucket 10c is swingably disposed on the front portion of the undercarriage 2 so as to perform a predetermined operation as a dozer blade.

[0034] A driver's seat 3a on which an operator sits and performs work is arranged on the upper par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com