Drive unit for hand tool machine

A hand-held machine tool and turbine technology, which is applied in the direction of manufacturing tools, metal processing machinery parts, portable mobile devices, etc., can solve the problems of low efficiency and insufficient vacuum cleaner suction power to meet the requirements, and achieve high power and high grinding The effect of quantity and good overall coordination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

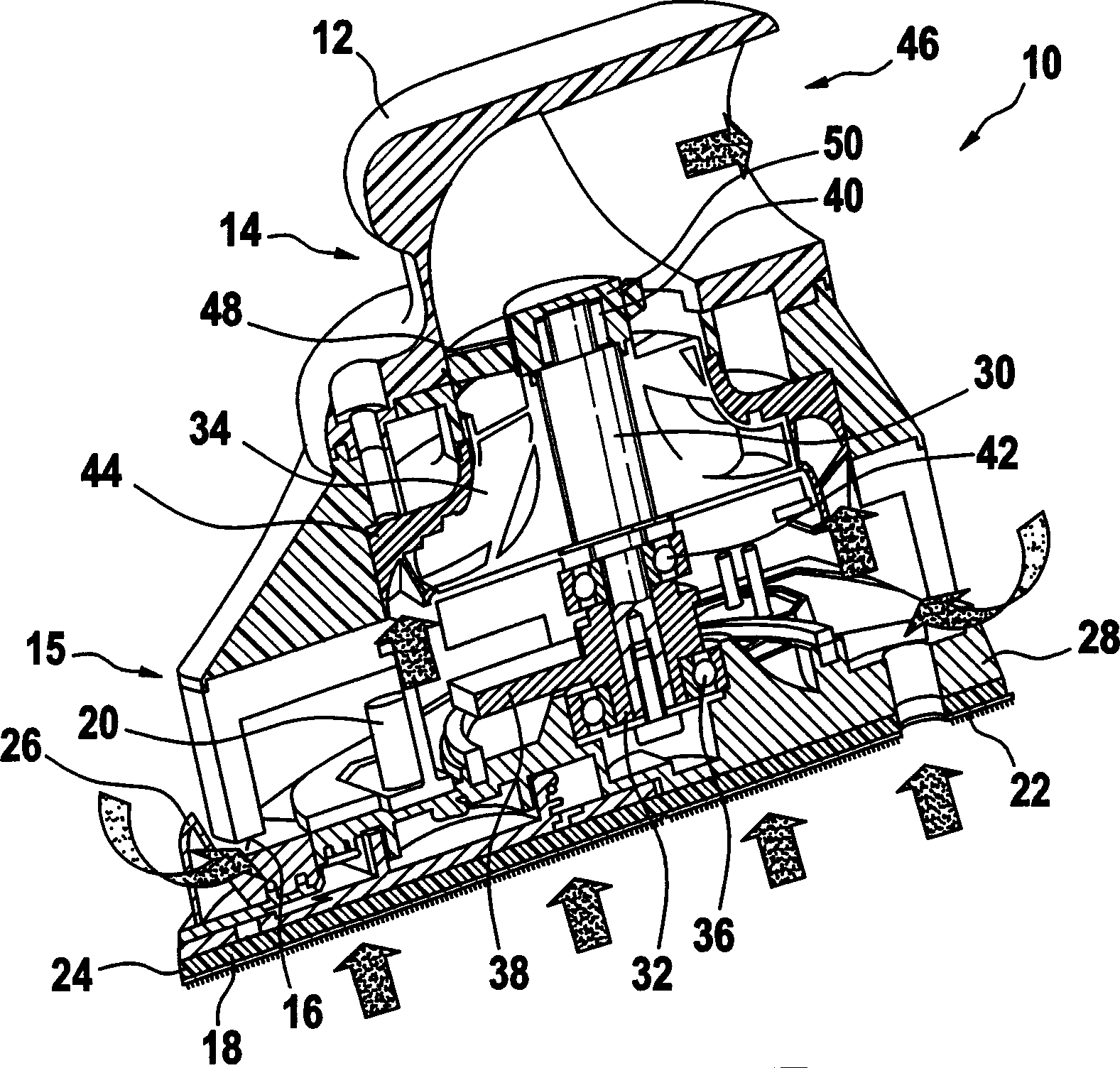

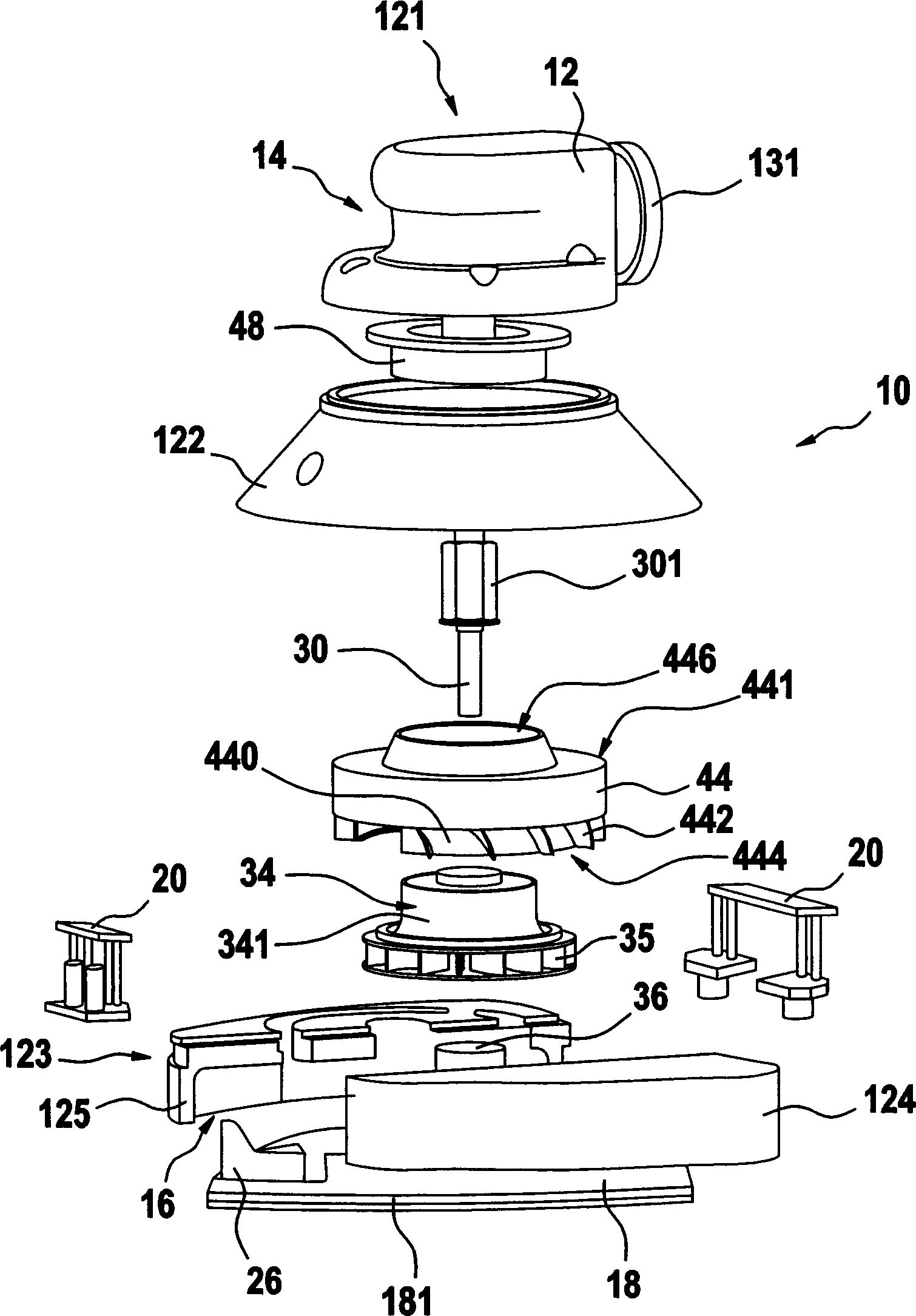

[0040] figure 1 A hand-held power tool 10 is shown, which is designed as a superfinishing machine. It comprises a housing 12 , configured in its upper region as a handle, which continues downwards into a waist-like constriction 14 which is easy to grip and then widens into a bell-shaped region 15 .

[0041] The housing 12 ends at the bottom with a rectilinear lower edge 16 which, in its downward vertical projection, is triangular with outwardly curved sides. Arranged parallel to the lower edge 16 is a grinding disk 18 which is elastically connected to the housing 12 via an elastic vibration element 20 . The grinding disk 18 protrudes with its iron-shaped base in the radial direction out of the vertically downward triangular projection of the lower edge 16 and has clamping means for receiving the sanding disc 22 on its base.

[0042] The grinding disk 18 carries a button 26 on the front central tip 24 , after actuating it, the grinding disk 18 can be removed from the housing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com