Method for controlling and/or regulating slipping motion of roller relative to strip, controller and/or regulator, machine-readable program code, storage medium and industrial plant

An adjustment device and program coding technology, which is applied in the direction of braking/tensioning device, transportation and packaging, tension/pressure control, etc., can solve the problems of production waste, damaged surface, affecting quality, etc., so as to improve reliability and yield , reduce the effect of slipping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

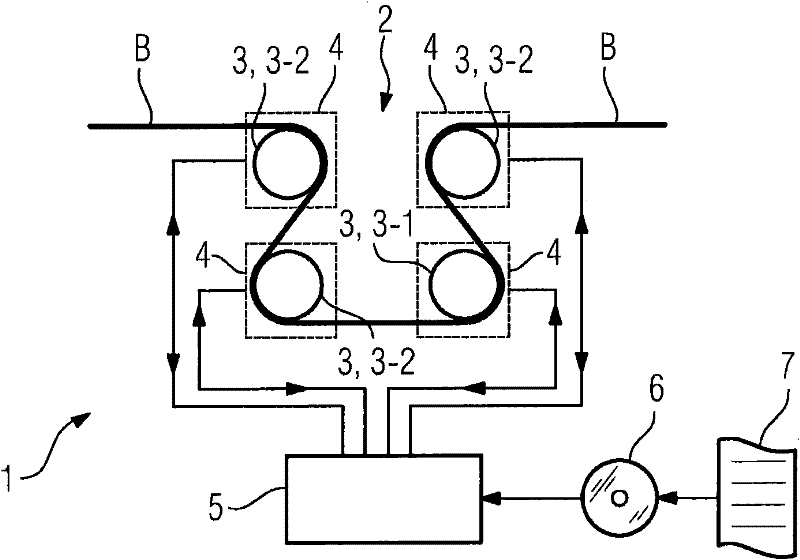

[0039] figure 1 The industrial plant shown is designed as a processing line 1 for processing metal strip B (in particular cold-rolled strip). This processing line 1 may comprise several areas for processing the metal strip B, such as a rolling area, an area for coating the metal strip, an area for cleaning the metal strip, an area for thermal conditioning of the cold-rolled strip and other areas. they are figure 1 not shown in .

[0040] This processing line 1 has in particular at least one roller set 2 . In the exemplary embodiment, this roll set 2 has four rolls 3 which guide the cold strip. This roller set 2 is used to adjust the strip tension of the metal strip B in the treatment pass 1 . Roller sets 2 are arranged in particular between the areas of the processing line 1 in which different strip tensions are set for processing the metal strip B.

[0041] It is also possible to use roll packs with more or less than four rolls in the industrial plant 1 , especially for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com