Method of seaming a knitted fabric piece

A technology of piece head and knitted fabric, which is applied in the field of trimming of knitted piece head

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

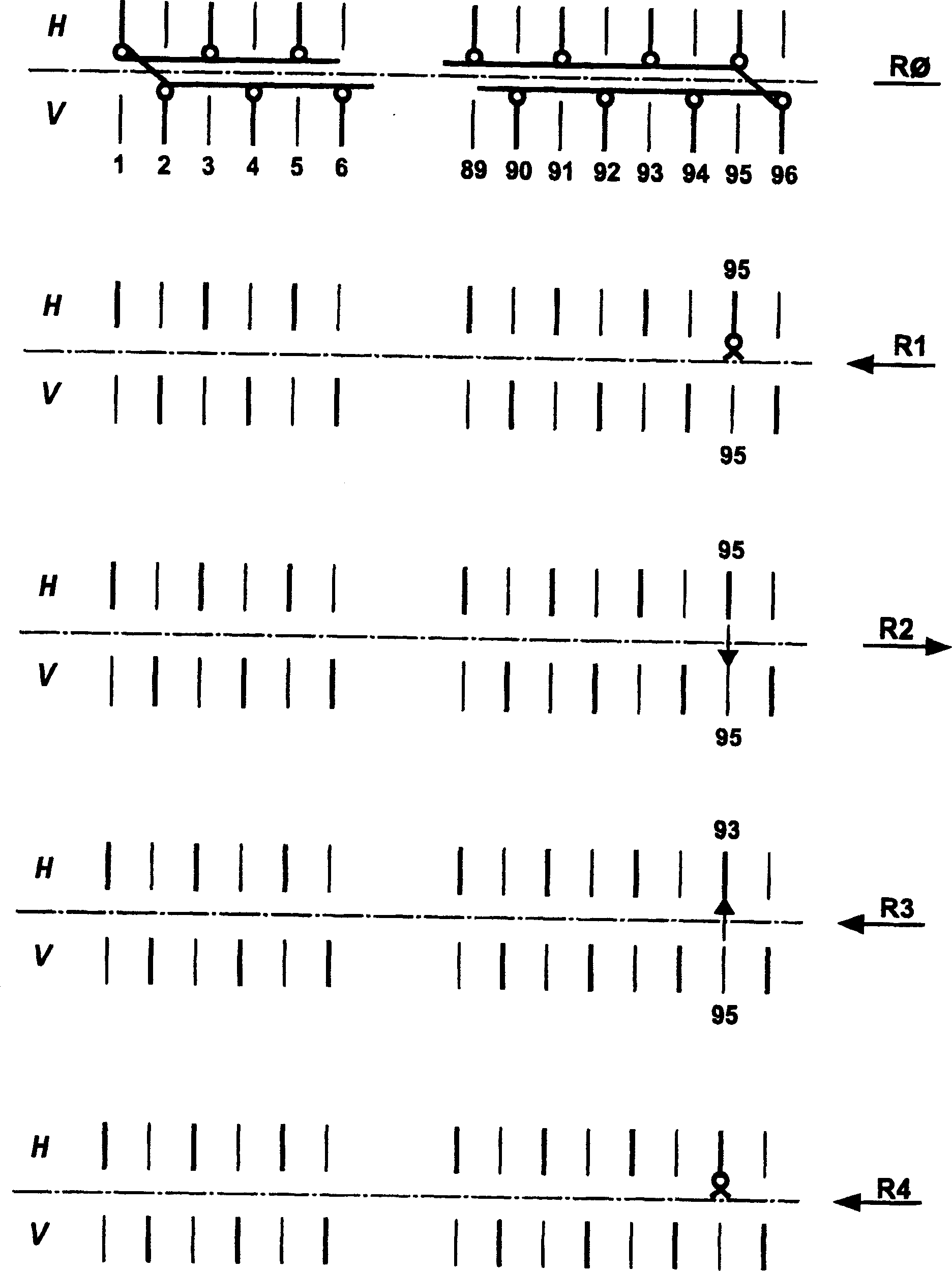

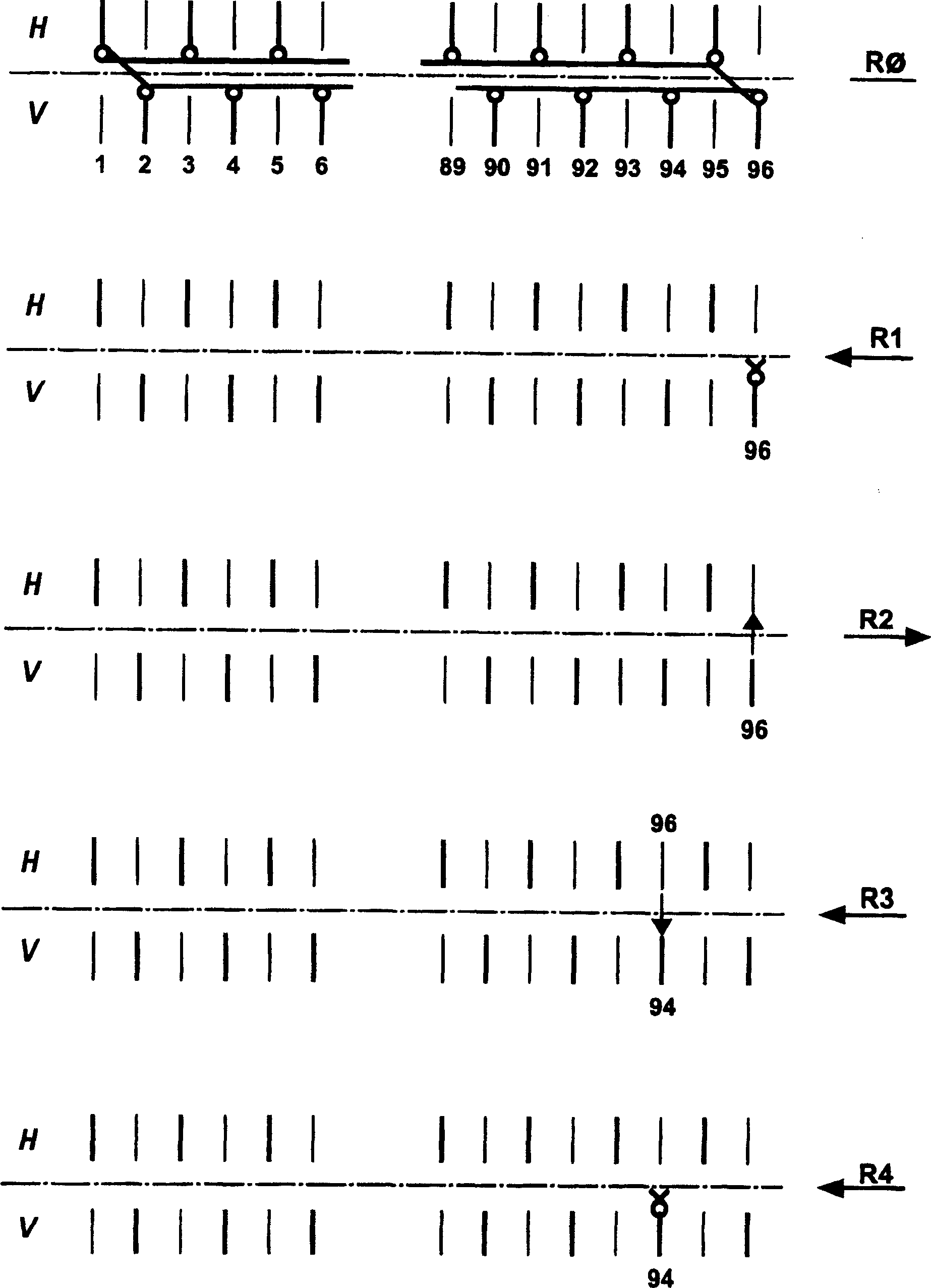

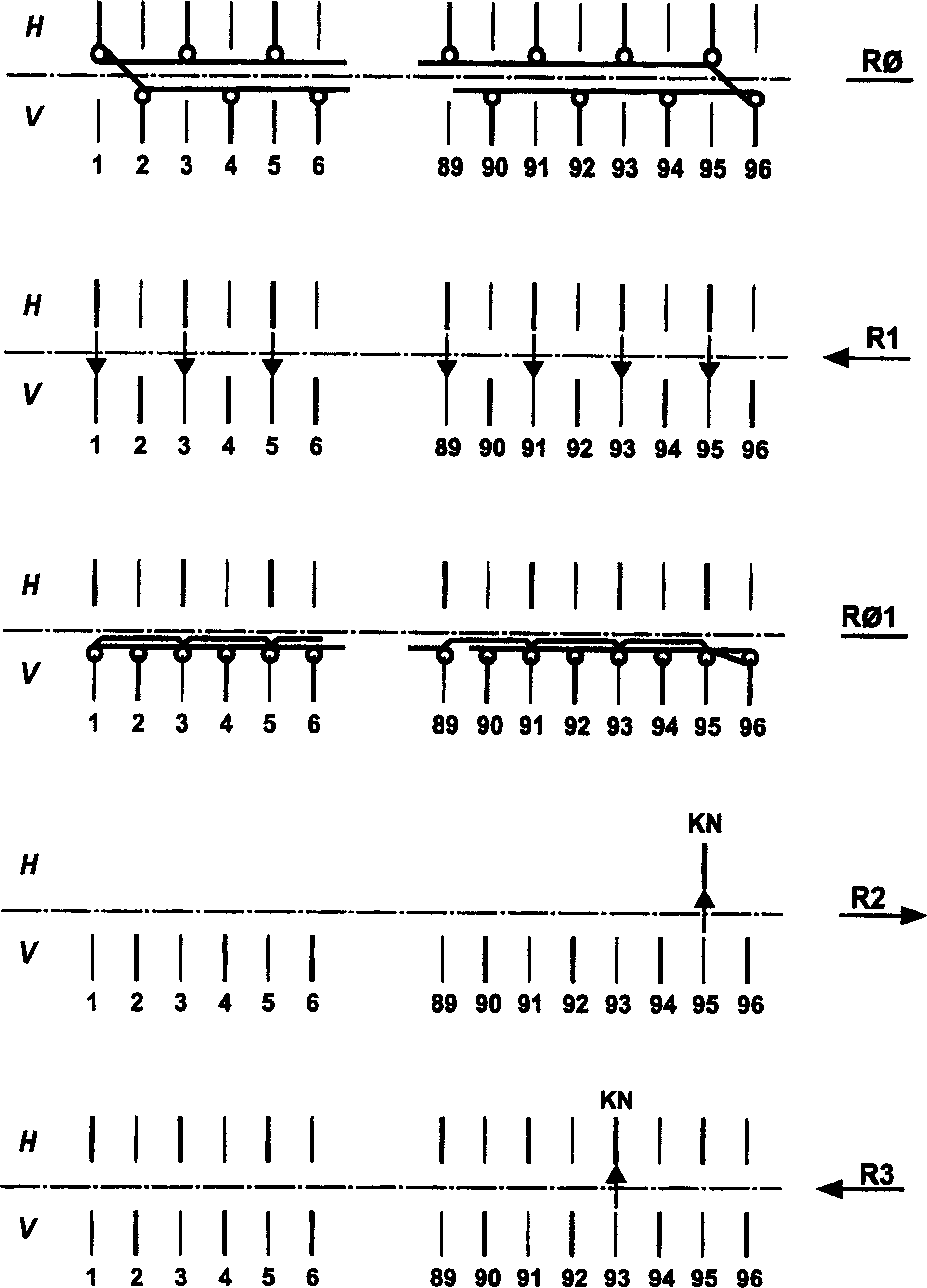

[0018] Figure 1.1 with Figure 1.2 Using the example of a tubular knitted fabric, the edge technology according to the prior art for forming a firm knit finish, which is required, for example, at a neckline or cuff, is illustrated. This second needle bed, here the rear needle bed H, can perform a traversing movement. The front needle bed V is then non-traversable in the example described. Of course, the roles of needle bed V and H can also be exchanged. Furthermore, it is also possible in principle to arrange the two needle beds so that they can be offset.

[0019] exist Figure 1.1 In the R0 course of , the last knitting course of the tubular-circular-finished knitted fabric is indicated. The fabric is constructed on the front and rear needle beds V, H. Each of the needles with a loop is aligned with an empty needle of the other needle bed. In the course R1, the back side of the knitted fabric on the rear needle bed H is trimmed. For this purpose, the outermost needles...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com