Device and method for removing dust for mining train loading station

A technology of dust removal device and loading station, which is applied in separation methods, chemical instruments and methods, and the use of liquid separation agents, etc. It can solve the problems of occupying a large working space, unsatisfactory dust removal effect, and harsh use conditions, and achieves simple installation, Dust removal implementation time is short and the effect of high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

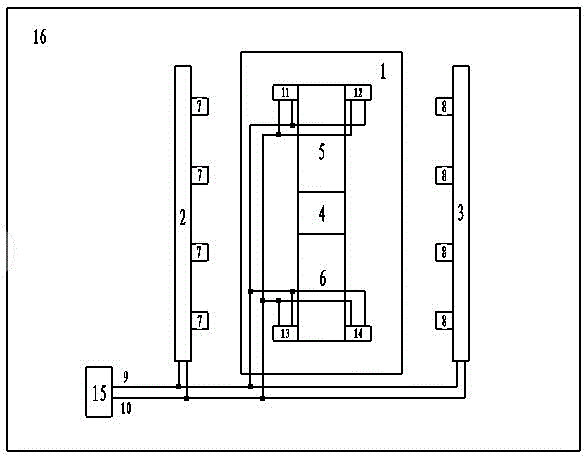

[0032] The device consists of an open train compartment 1, a spray dust removal device and an air-water distribution device on the left side 2, a spray dust removal device and an air-water distribution device 3 on the right side, a chute for materials to be loaded 4, a swingable feeding device 5 before the materials, and a Rear swingable feeding device 6, left water vapor atomization nozzle group 7, right water vapor atomization nozzle group 8, pressure water main pipe 9, pressure gas main pipe 10, material front swingable feeding device left water vapor atomization nozzle 11. Water vapor atomization nozzle on the right side of the swingable feeding device before the material 12. Water vapor atomization nozzle on the left side of the swingable feeding device after the material 13. Water vapor atomization nozzle on the right side of the swingable feeding device after the material 14. Intelligent spray control The device 15 is composed of a loading structure 16. The open-ended tr...

Embodiment approach 2

[0037] The left water vapor atomization nozzle group 7 constitutes 5 nozzles, the right water vapor atomization nozzle group 8 constitutes 5 nozzles, and the pressure water is 3.5kgf / cm 2 , the working pressure range of compressed air is 4kgf / cm 2 , the water-gas volume ratio is 100:2, and the water-gas atomizing nozzle group 8 on the right side acts together on the upper part of the train open compartment 1 to form a 200 mm higher than the open compartment, and the others are the same as in Embodiment 1.

Embodiment approach 3

[0039] The left water vapor atomization nozzle group 7 consists of 6 nozzles, the right water vapor atomization nozzle group 8 consists of 6 nozzles, and the pressure water is 2.5kgf / cm 2 , the working pressure range of compressed air is 3.5kgf / cm 2 , the water-gas volume ratio is 100:3, and the water-gas atomizing nozzle group 8 on the right side acts together on the upper part of the train open compartment 1 to form a 10 mm higher than the open compartment, and the others are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com