Compensating method for control loop oscillation due to viscosity property of valve

A technology of control loop and viscous characteristics, applied in the direction of adaptive control, general control system, control/regulation system, etc., can solve the problems of negative process negative influence and large amplitude, so as to reduce negative effects, improve production process efficiency, The effect of shortening the implementation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

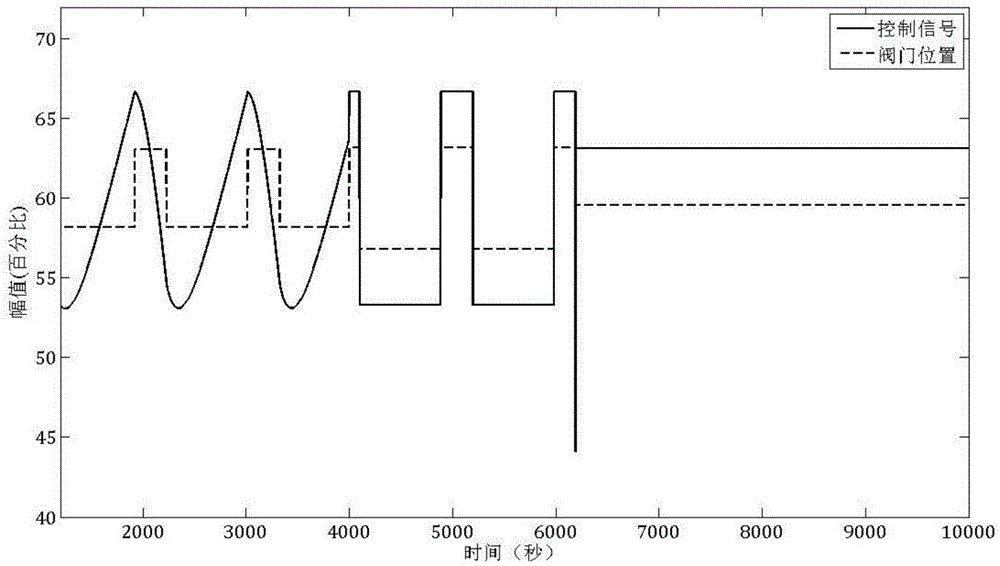

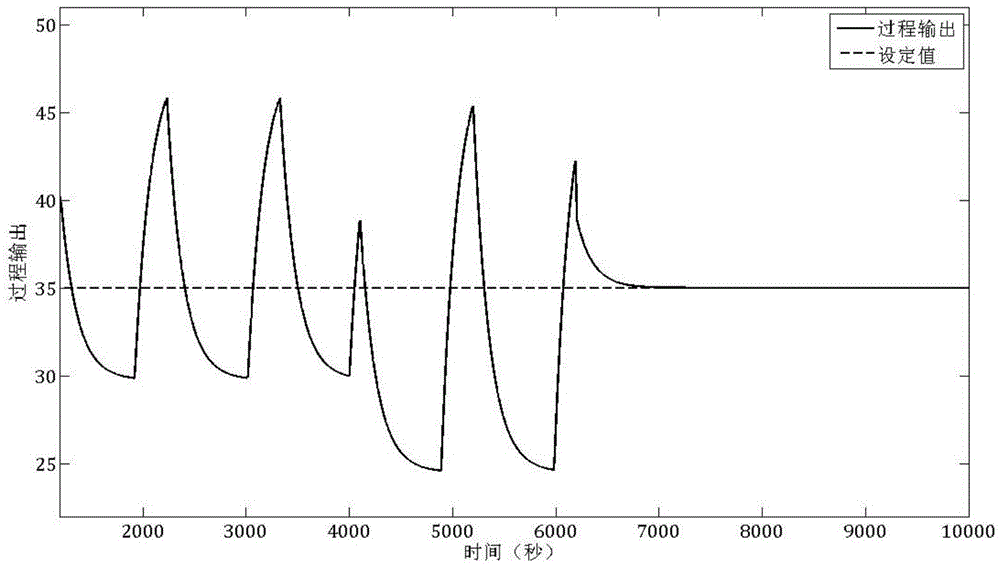

[0076] Taking the viscous compensation of the regulating valve of the cooling water circuit in a large domestic power plant as an example, the compensation method of the present invention for controlling the oscillation caused by the viscous characteristic of the regulating valve will be described in detail below.

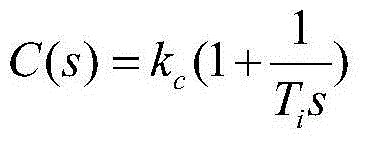

[0077] The loop process uses a first-order pure lag model The controller adopts PI control Setpoint of the process output signal r ss 35m 3 / h (cubic meter / hour), the static offset constant c=-192.3411 of the process output, regardless of the external disturbance. The cooling water flow regulating valve has viscous characteristics, and the valve viscous model adopts the He model, and the viscous parameters are f s =8.4, f d = 3.5243.

[0078] This embodiment includes the following steps:

[0079] Step 1. After detecting the oscillation phenomenon in the process loop, switch the control to the open-loop mode and output a set of control signals m(t).

[0080...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com