Polyestercarbonates and methods of manufacture

一种聚酯碳酸酯、碳酸二酯的技术,应用在聚酯碳酸酯领域,能够解决数据不准确、扭曲、可靠性降低等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

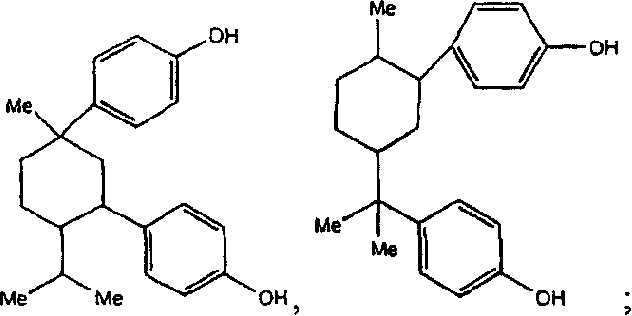

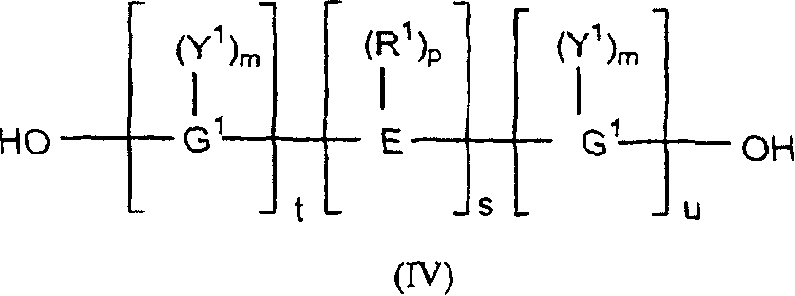

[0084] In the preparation of polyester carbonates, the above-mentioned aromatic dihydroxy compound comonomers may be used alone, or as a mixture of two or more different aromatic dihydroxy compound comonomers. In a particular embodiment, a suitable aromatic dihydroxy compound comonomer for the preparation of polyester carbonates is 2,2-bis(4-hydroxyphenyl)propane (commonly known as bisphenol A or "BPA") ), resorcinol, 4,4′-(1-(1-decylene)-diphenol (hereinafter sometimes referred to as “bispded”) and 2,2-bis(3-sec-butyl-4 -Hydroxyphenyl)propane (hereinafter sometimes also referred to as "s-BPA"), or a mixture containing at least one of the aforementioned aromatic dihydroxy compounds.

[0085] In certain embodiments, polyester carbonates are prepared from dicarboxylic acid diesters selected from the following formula (X),

[0086]

[0087] where Y is the formula (CH 2 ) n wherein n has a value in the range of about 4 to about 18, and R' is phenyl. In a specific embodiment...

Embodiment 1-2

[0125] Embodiment 1-2, comparative example 1-3

[0126] Polyester carbonates were prepared using the general polymerization method described above. For each polyester carbonate prepared, glass transition temperature, molecular weight and swelling data were measured using the general method described above. The results are shown in Table 1 below. All reactions were performed using a molar ratio of 1.08 of diphenyl carbonate to a mixture of X, aromatic dihydroxy compound comonomer, and dicarboxylic acid diester. The catalyst used was a mixture of sodium hydroxide and tetramethylammonium hydroxide each in a molar ratio of 1:100. In each case, 2.5 x 10 -4 moles of tetramethylammonium hydroxide. Comparative Example 1 refers to BPA homopolycarbonate prepared by the general method described above using BPA and diphenyl carbonate. Comparative Example 2 refers to monomer 1,1-bis(4-hydroxyphenyl)-3,3,5-trimethylcyclohexane and 4,4'-(m-phenylene) in a molar ratio of 45:55 A polycar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com