Titanium carbide nanosheet/carbon nanotube electromagnetic shielding film and preparation method thereof

An electromagnetic shielding and carbon nanotube technology, which is applied in the fields of magnetic field/electric field shielding, electrolytic coatings, electrical components, etc., can solve problems such as difficulty in ensuring dispersion, difficulty in achieving ideal electrical properties and shielding properties, and easy agglomeration of carbon nanomaterials. Achieve the effects of good mechanical properties, excellent electromagnetic shielding efficiency, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

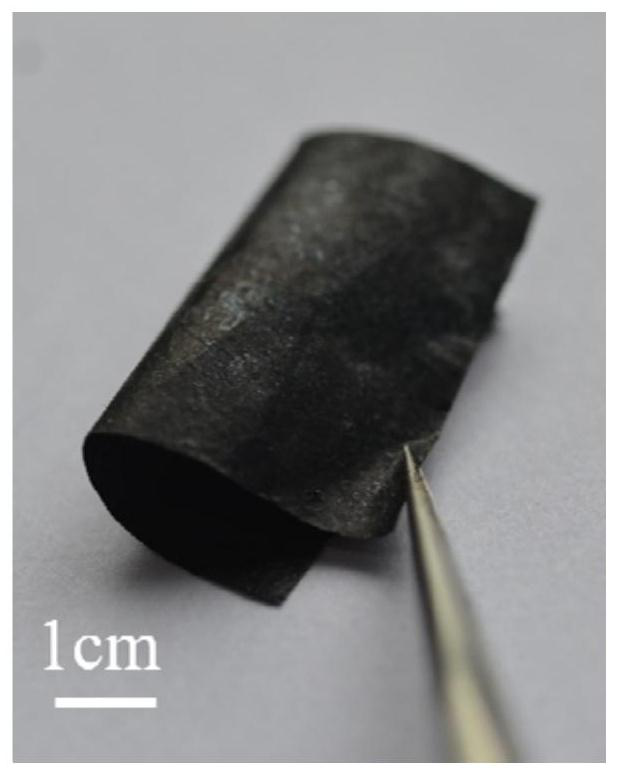

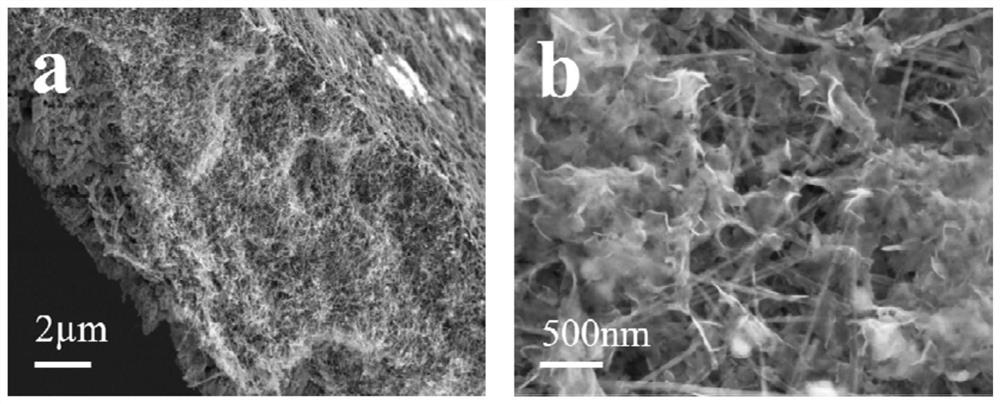

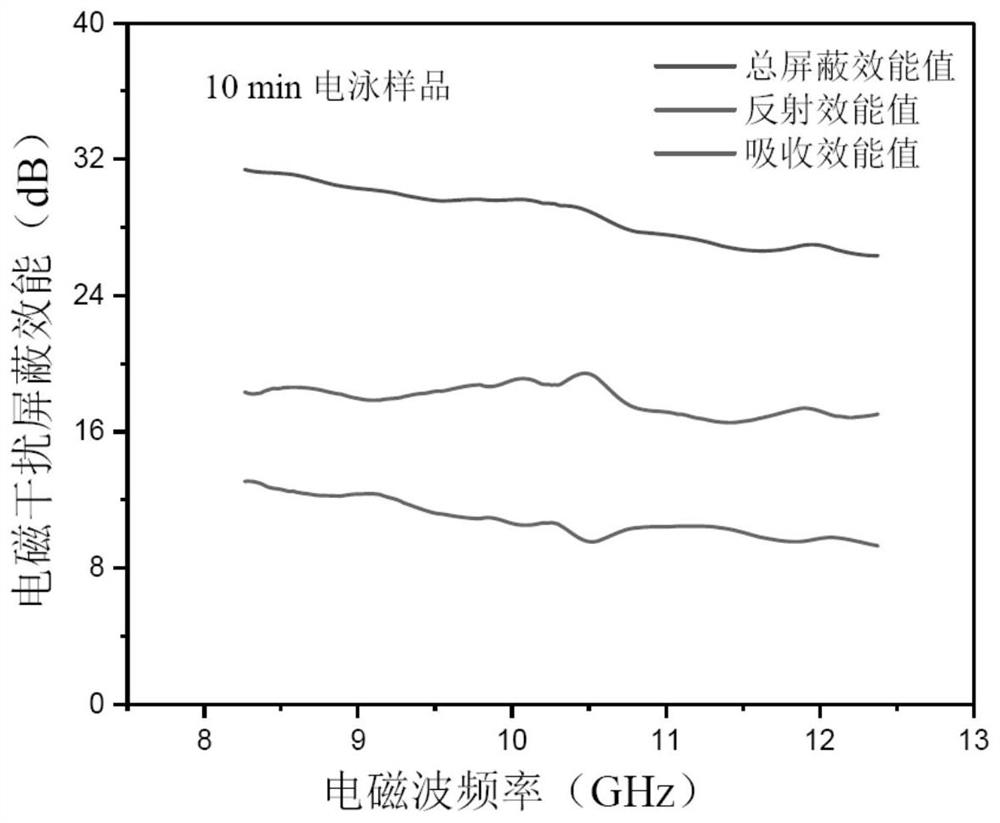

Image

Examples

Embodiment 1

[0029] A method for preparing titanium carbide nanosheet / carbon nanotube composite film by electrophoretic deposition, comprising the following steps:

[0030] 1) Using titanium carbide aluminum block as raw material, prepare titanium carbide nanosheet powder by chemical etching method. The etching reagent is LiF / HCl. Perform high-speed centrifugation on the etching dispersion liquid three times to separate the upper layer solution. 3000rpm, 5000rpm, and 8000rpm respectively. The centrifuged solution was vacuum filtered and freeze-dried to obtain powdered titanium carbide nanosheets, wherein the size of a single nanosheet was 50nm-50μm, and then the titanium carbide nanosheet powder was quantitatively dispersed in H 2 In O, the concentration is 0.1mg / mL, without adding additional reagents;

[0031] 2) The carbon nanotube film with a thickness of 10 μm prepared by chemical vapor deposition is used as the working electrode, and the titanium carbide nanosheet base dispersion liqu...

Embodiment 2

[0035] A method for preparing titanium carbide nanosheet / carbon nanotube composite film by electrophoretic deposition, comprising the following steps:

[0036] 1) Using titanium aluminum carbide block as raw material, prepare titanium carbide nanosheet powder by chemical etching method, the etching reagent is LiF / HCl, perform three high-speed centrifugation on the dispersion liquid obtained by etching, separate the upper layer solution, and centrifuge The rotational speeds are 3000rpm, 5000rpm, and 8000rpm respectively, and the centrifuged solution is vacuum filtered and freeze-dried to obtain powdered titanium carbide nanosheets.

[0037] Among them, the size of a single nanosheet is 50nm-50μm, and then the titanium carbide nanosheet powder is quantitatively dispersed in H 2 In O, the concentration is 1mg / mL, without adding additional reagents;

[0038] 2) The 20 μm carbon nanotube film prepared by chemical vapor deposition was used as the working electrode, and the titanium...

Embodiment 3

[0043] A method for preparing titanium carbide nanosheet / carbon nanotube composite film by electrophoretic deposition, comprising the following steps:

[0044] 1) Using titanium aluminum carbide block as raw material, prepare titanium carbide nanosheet powder by chemical etching method, the etching reagent is LiF / HCl, perform three high-speed centrifugation on the dispersion liquid obtained by etching, separate the upper layer solution, and centrifuge The rotational speeds are 3000rpm, 5000rpm, and 8000rpm respectively, and the centrifuged solution is vacuum filtered and freeze-dried to obtain powdered titanium carbide nanosheets.

[0045] Among them, the size of a single nanosheet is 50nm-50μm, and then the titanium carbide nanosheet powder is quantitatively dispersed in H 2 In O, the concentration is 1mg / mL, without adding additional reagents;

[0046] 2) The 20 μm carbon nanotube film prepared by chemical vapor deposition was used as the working electrode, and the titanium...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com