Light guide plate and backlight device

A technology of backlight device and light guide plate, applied in the field of light guide plate, which can solve the problem of small light ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

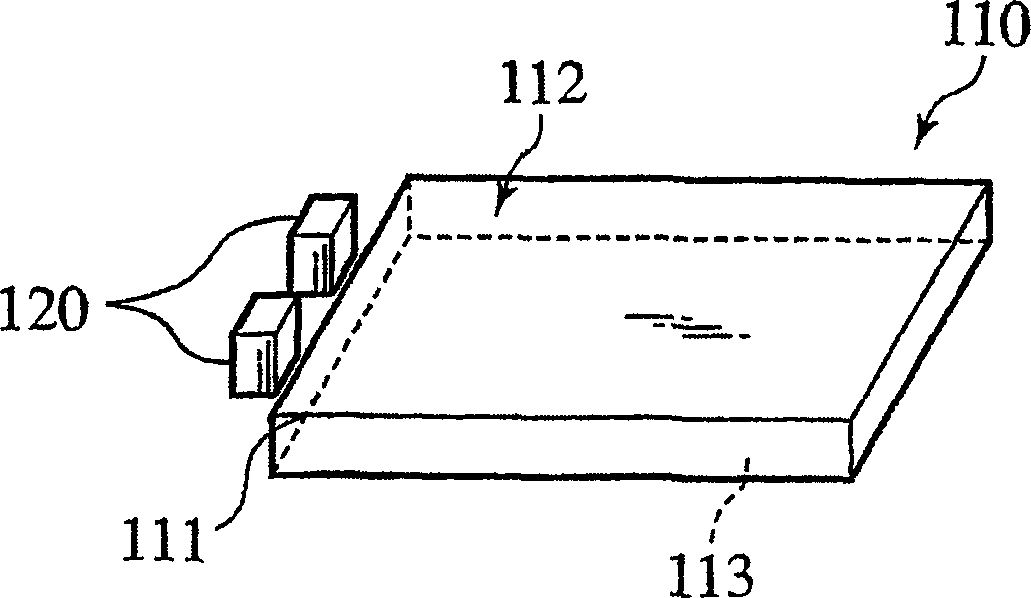

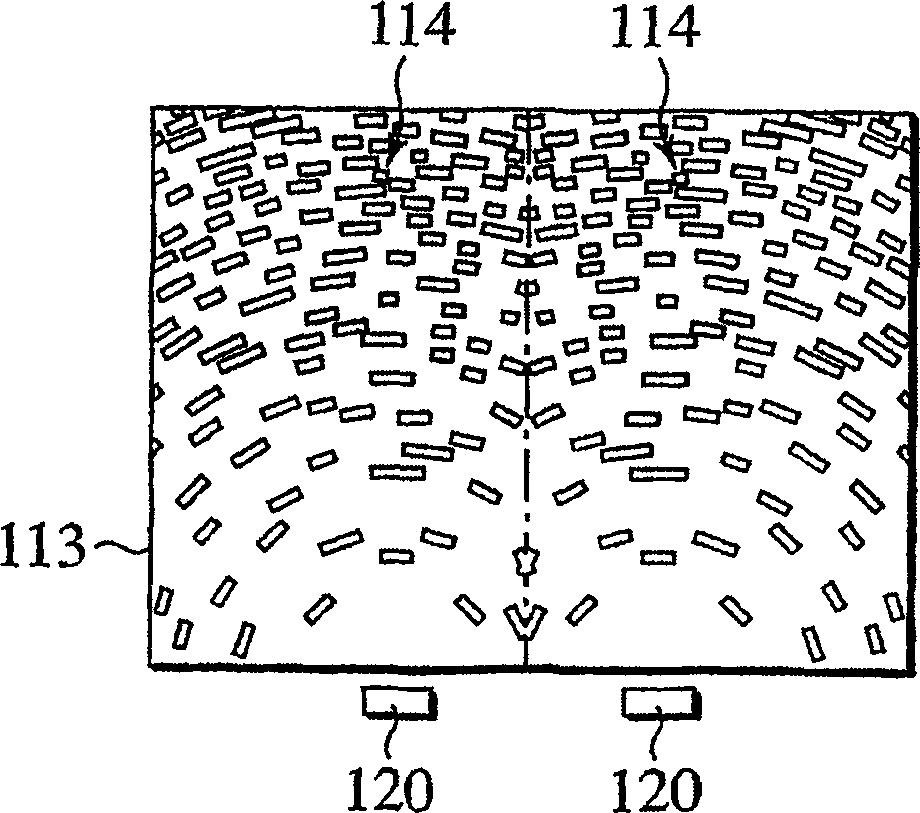

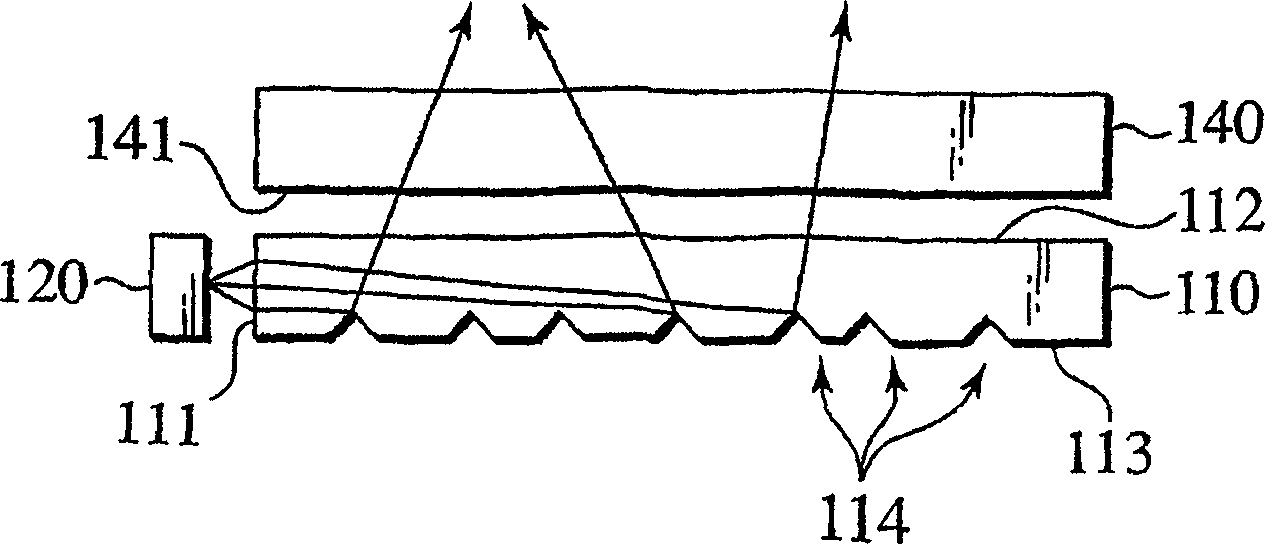

[0120] First, a first embodiment of the present invention will be described. In the first embodiment, the notch surface (round shape) formed on one side surface of the apex of the substantially rectangular light guide plate is used as the incident surface, and the light incident on the light guide plate from one light source repeats total reflection while repeating total reflection. Entering the light guide plate, every time it is reflected by the reflection groove, the angle will gradually rise, so that the angle relative to the exit surface will gradually become smaller, and it will exit from the exit surface as soon as the critical angle is reached.

[0121] Figure 3A , Figure 3B And FIG. 3C is a diagram showing the outline of the light guide plate of the first embodiment. A light emitting diode (LED) 20 of the light source is also shown in the figure at the same time.

[0122] Figure 3A is a top view of the light guide plate 10, Figure 3B 3C is a front view of the...

no. 2 example

[0182] Next, a second embodiment of the present invention will be described. In the second embodiment, the notch surface formed on one side surface of the vertex of the substantially rectangular light guide plate is used as the incident surface, and the light incident on the light guide plate from one light source enters the light guide plate while repeating total reflection, If it is reflected by the reflection groove, it will emerge from the exit surface at a small exit angle.

[0183] In addition, since this embodiment has the same structure as the above-mentioned first embodiment except for the reflective groove, the same symbols are attached to the common parts and their descriptions are omitted.

[0184] Figure 15A, Figure 15B And FIG. 15C is a schematic view showing the light guide plate of the second embodiment. A light emitting diode (LED) 20 of the light source is also shown in the figure.

[0185] 15A is a top view of the light guide plate 10, Figure 15B is a ...

no. 3 example

[0200] Next, a third embodiment of the present invention will be described. In the third embodiment, one side surface of the substantially rectangular light guide plate 10 is used as the incident surface, and light incident on the light guide plate from a plurality of light sources enters the light guide plate while repeating total reflection, and is reflected by the reflection groove. When , the angle will be gradually erected, so that the angle relative to the exit surface will gradually become smaller, and when the critical angle is reached, it will exit from the exit surface.

[0201] In addition, since the present embodiment has the same structure as that of the above-mentioned first embodiment except for the arrangement of the light source and reflection grooves, etc., the common parts are given the same reference numerals and their descriptions are omitted.

[0202] Figure 18A , Figure 18B And FIG. 18C is a schematic view showing the light guide plate of the third e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com