Ink box assembly of printer and its control method

A technology of printers and ink cartridges, which is applied to the general parts of printing machinery, printing machines, printing, etc., can solve the problems of many opening errors and the inability to eliminate ink leakage, and achieve the effects of improving precision, reducing mechanical errors, and eliminating leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Embodiments of the present invention will be described below with reference to the accompanying drawings.

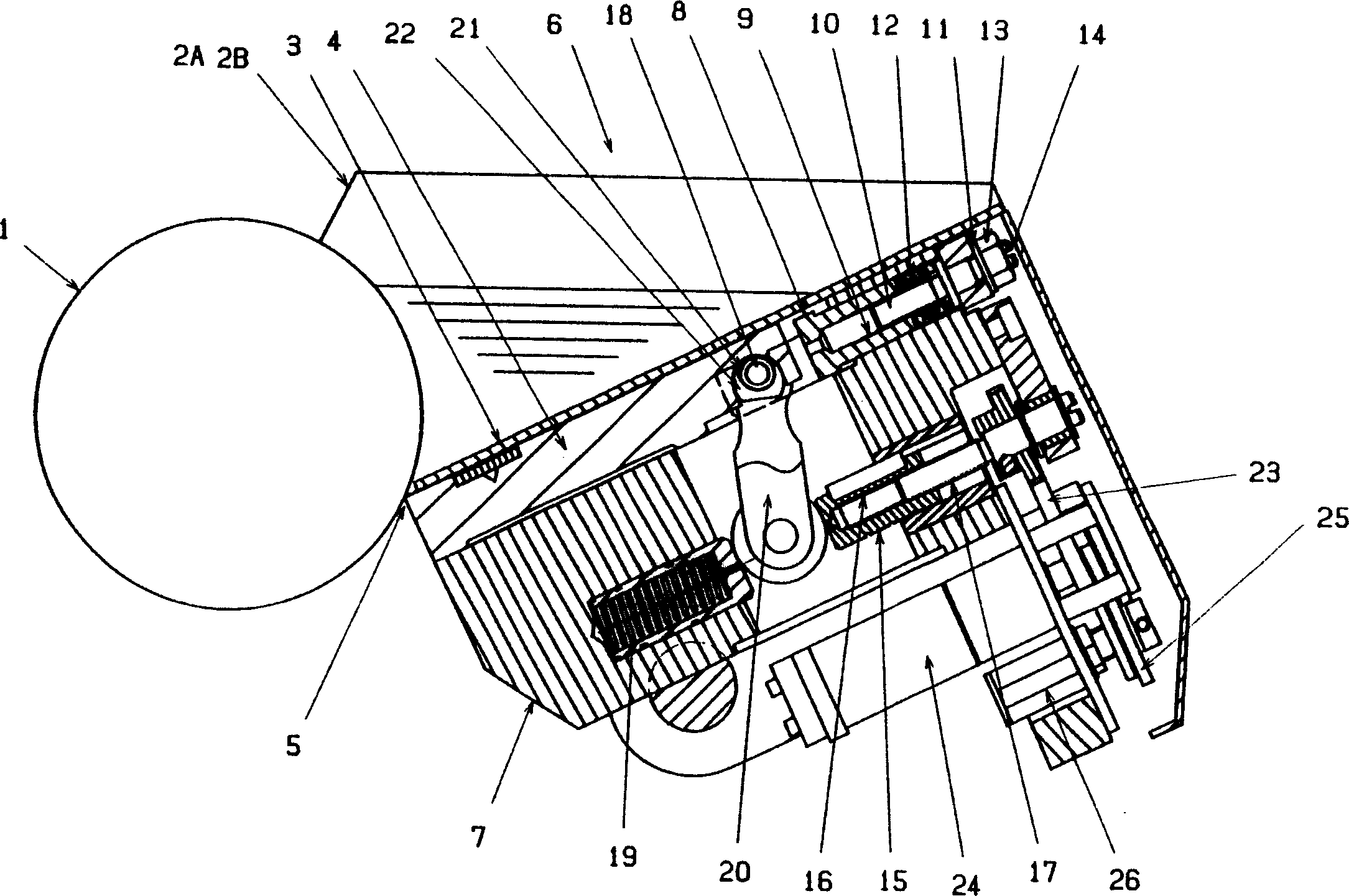

[0026] exist figure 1 Among them, the front face of the rotating ink cartridge represented by reference numeral 6 is surrounded by ink main roller 1, its left and right sides are surrounded by a pair of ink weirs 2A, 2B, and its rear and bottom are surrounded by inclined bottom panel 3.

[0027] In addition, a plurality of ink keys 4 are provided on the bottom side of the bottom panel 3, and these ink keys 4 traverse in a state of being in close contact with the front edge of the bottom panel 3. With the rotation of the main ink roller 1, the ink flows from the main ink roller The gap between ink key 1 and ink key 4, that is, the ink delivery slit t, continuously flows out, and approaches and separates toward the outer peripheral surface of ink main roller 1, and then is in a state of being in contact with it. On the bottom side of these ink keys 4 , there is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com