Badge and badge manufacturing device

A technology for manufacturing devices and badges, which is applied in the main field of badges, and can solve the problems of pattern paper manufacturing badges, manufacturing difficulties, damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

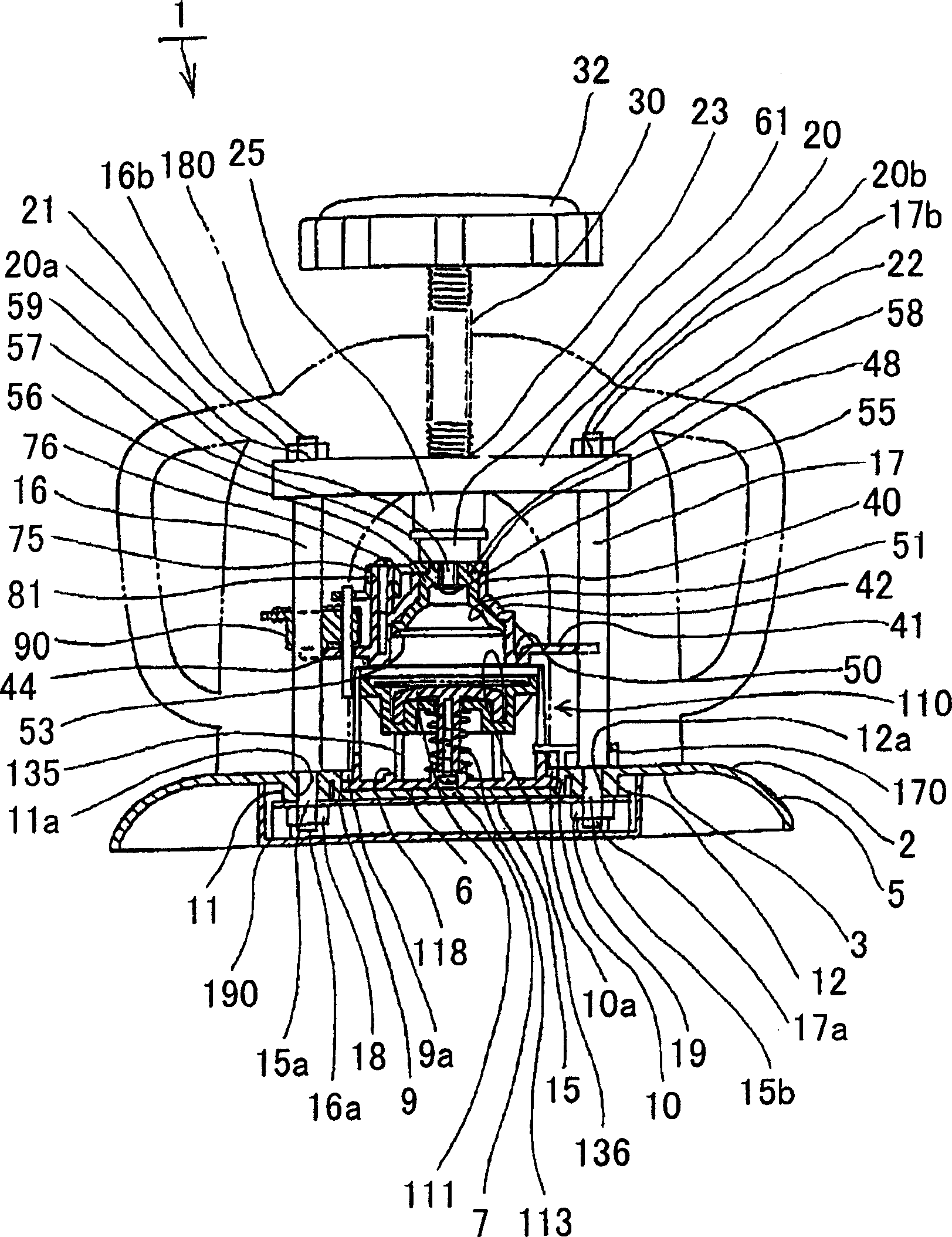

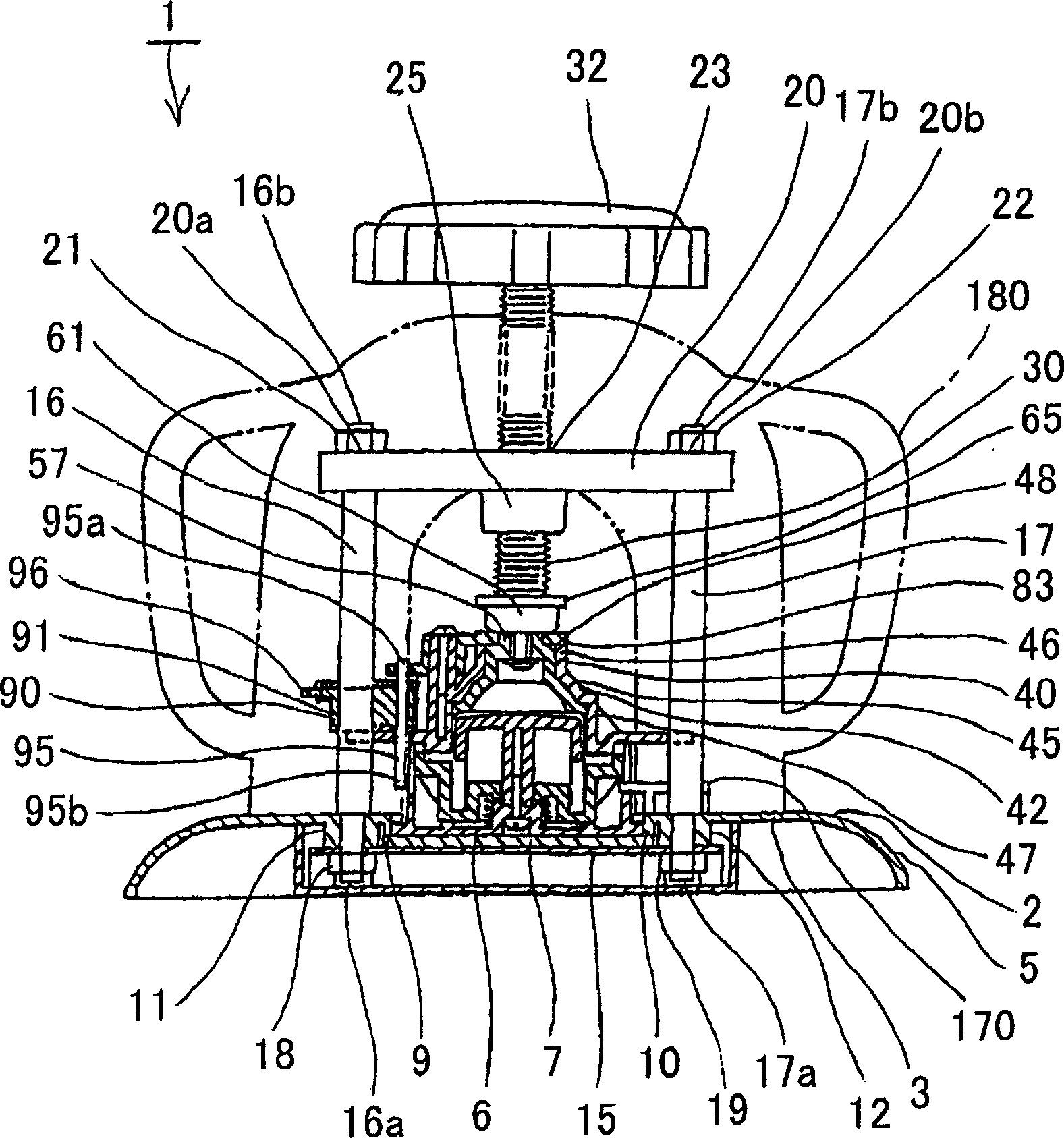

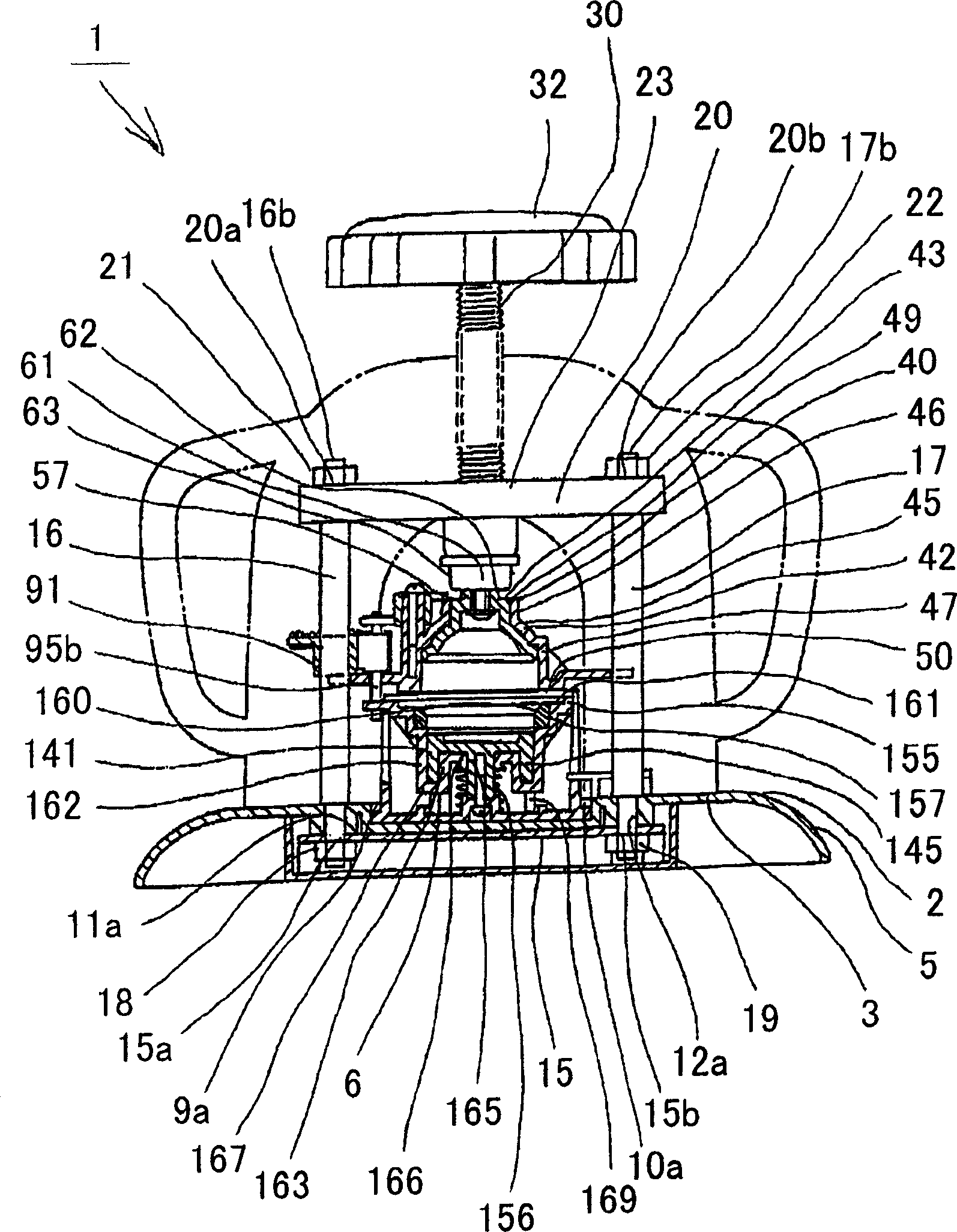

[0094] according to Figure 11 ~ Figure 20 An embodiment of the badge of the present invention will be described. The badge 200 includes a badge body 200a and wearing mechanisms 229, 237, 246, wherein the badge body is made up of: a bezel having a substantially circular face plate 202 and a cover periphery 203 extending downward from the face plate 202 cover 201; sheet body 213 placed on the surface plate 202 of the above-mentioned surface cover 201; an inner cover 205 having a substantially circular inner plate 206 and an inner cover peripheral edge 209 extending upward from the inner plate 206; the inner cover 205 Embedded on the above-mentioned watch cover 201 in this way, that is, the peripheral edge of the above-mentioned sheet body 213 is clamped between the inner cover peripheral edge 209 and the watch cover peripheral edge 203 , so that the above-mentioned sheet body 213 is in close contact with the surface plate 202 . The wearing mechanism is the wearing mechanism 22...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap