Apparatus for removing developer

A developing solution and removal technology, which is applied in the direction of diffusion developing equipment, exposure device for photo-plate making process, photography, etc., can solve the problems of slow operation speed and low safety, reduce the probability of fragmentation, improve safety and save The effect of operating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

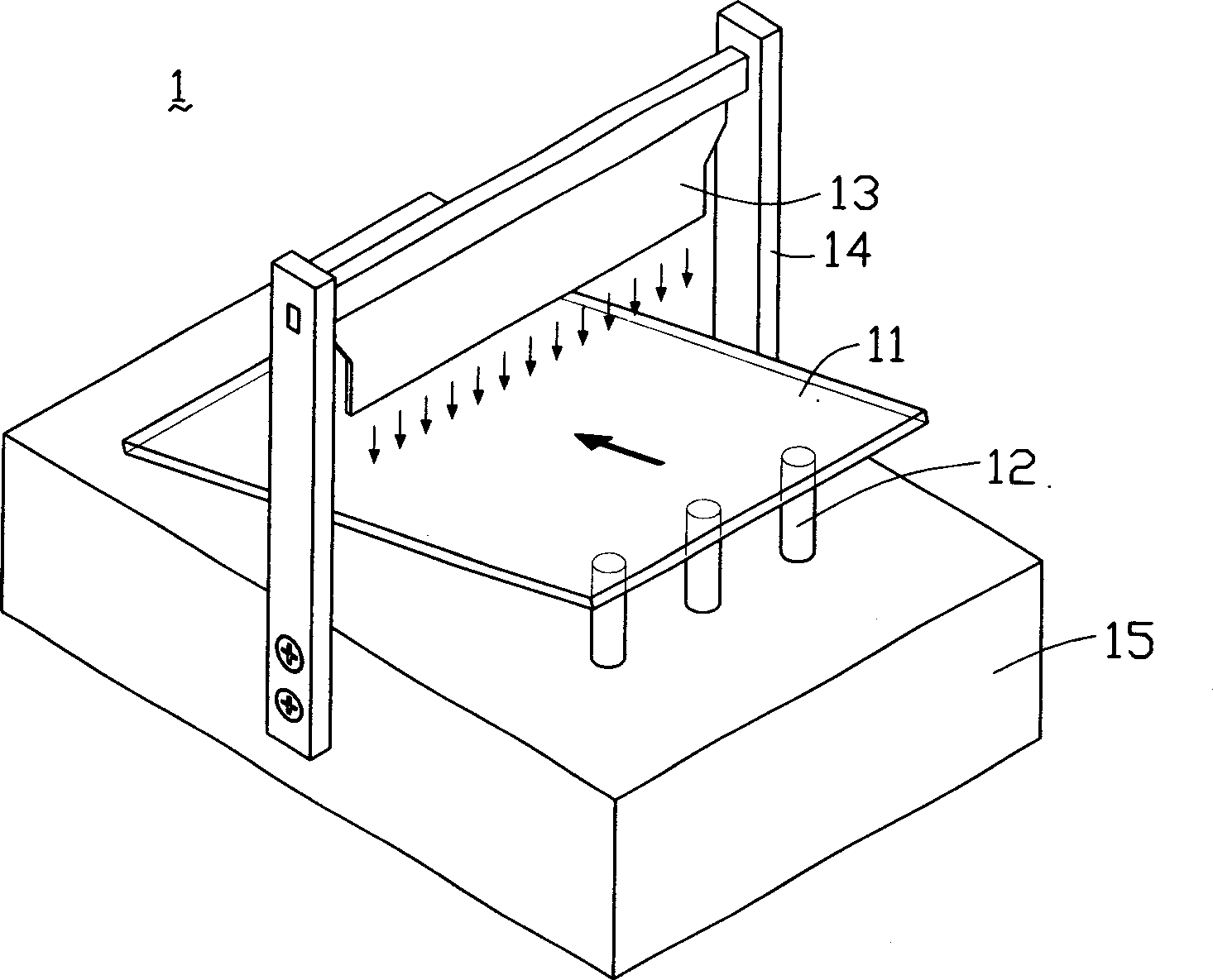

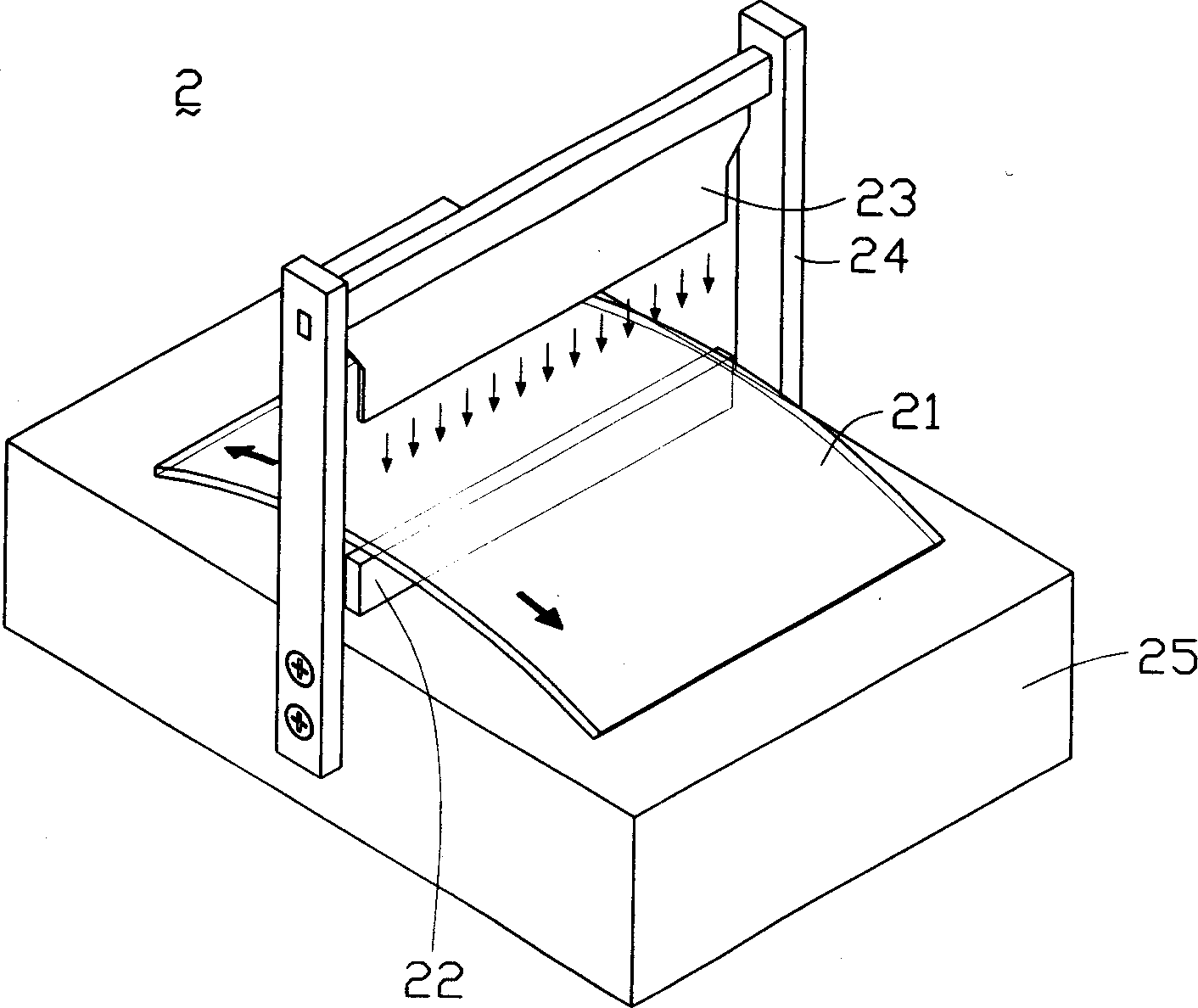

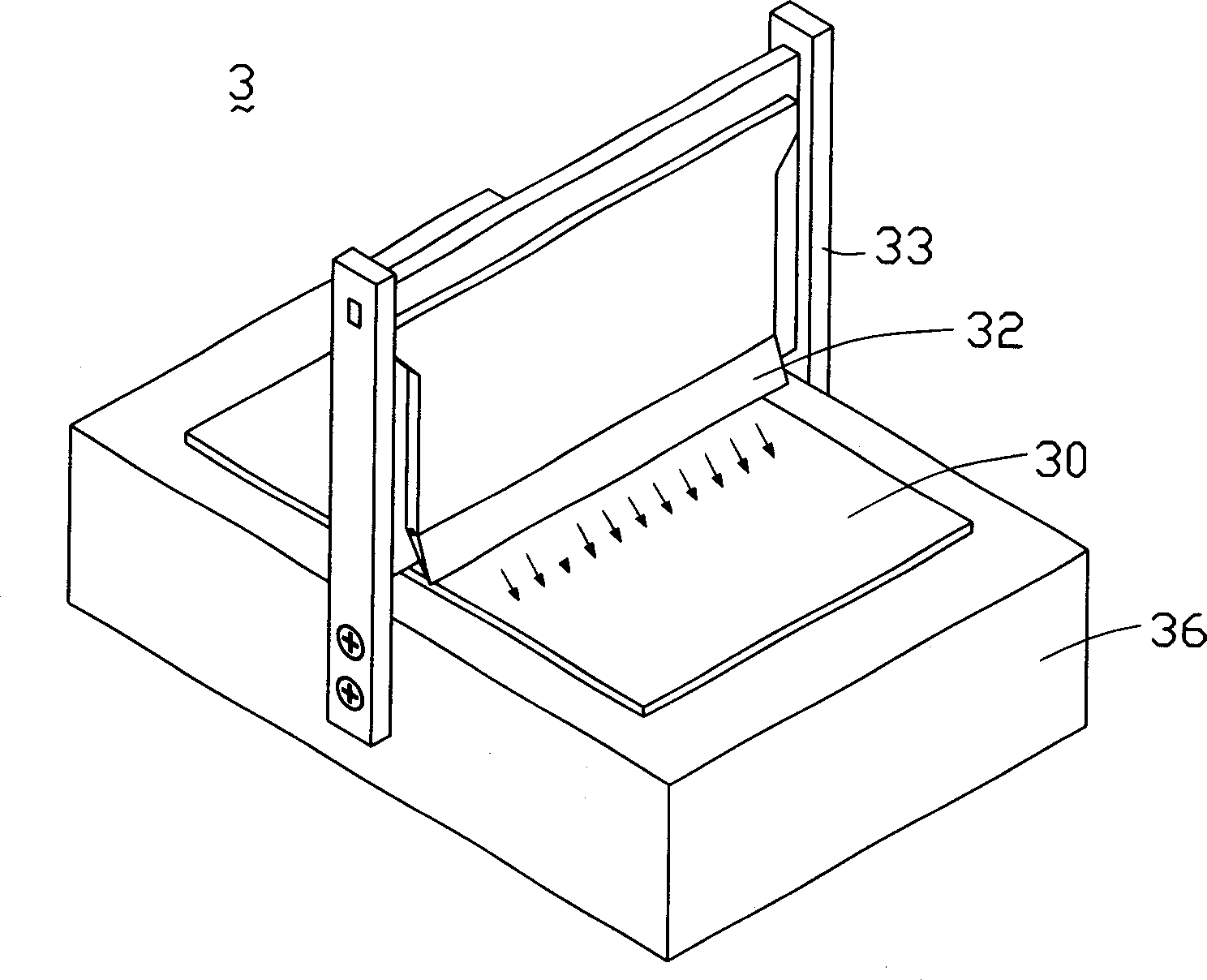

[0013] Please refer to image 3 with Figure 4 , image 3 Is a perspective view of the first embodiment of the developer removing device of the present invention, Figure 4 It is a plan view of the first embodiment of the developer removing device of the present invention. The developer removal device 3 of the present invention includes a workbench 36, a support 33, a nozzle support bridge 37, a gas nozzle 31, and a deionized water nozzle 32. The workbench 36 is used to carry the substrate 30. The support 33 is fixed on the workbench 36, and the nozzle support bridge 34 is fixed on the support 33. The gas nozzle 31 and the ionized water nozzle 32 are respectively located on both sides of the nozzle support bridge 34. In addition, the gas nozzle 31 and the ionized water nozzle 32 are connected to the nozzle support bridge 37 through the hubs 34 and 35, respectively, so that the gas nozzle 31 and the ionized water nozzle 32 can spray gas and deionized water to the substrate at differe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com