Semiconductor light emitting device and fabrication method thereof

A technology for light-emitting devices and semiconductors, applied to semiconductor devices, electrical solid-state devices, electrical components, etc., can solve problems such as no record of lead frames, and achieve the effects of reducing unevenness, reducing size, and improving heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

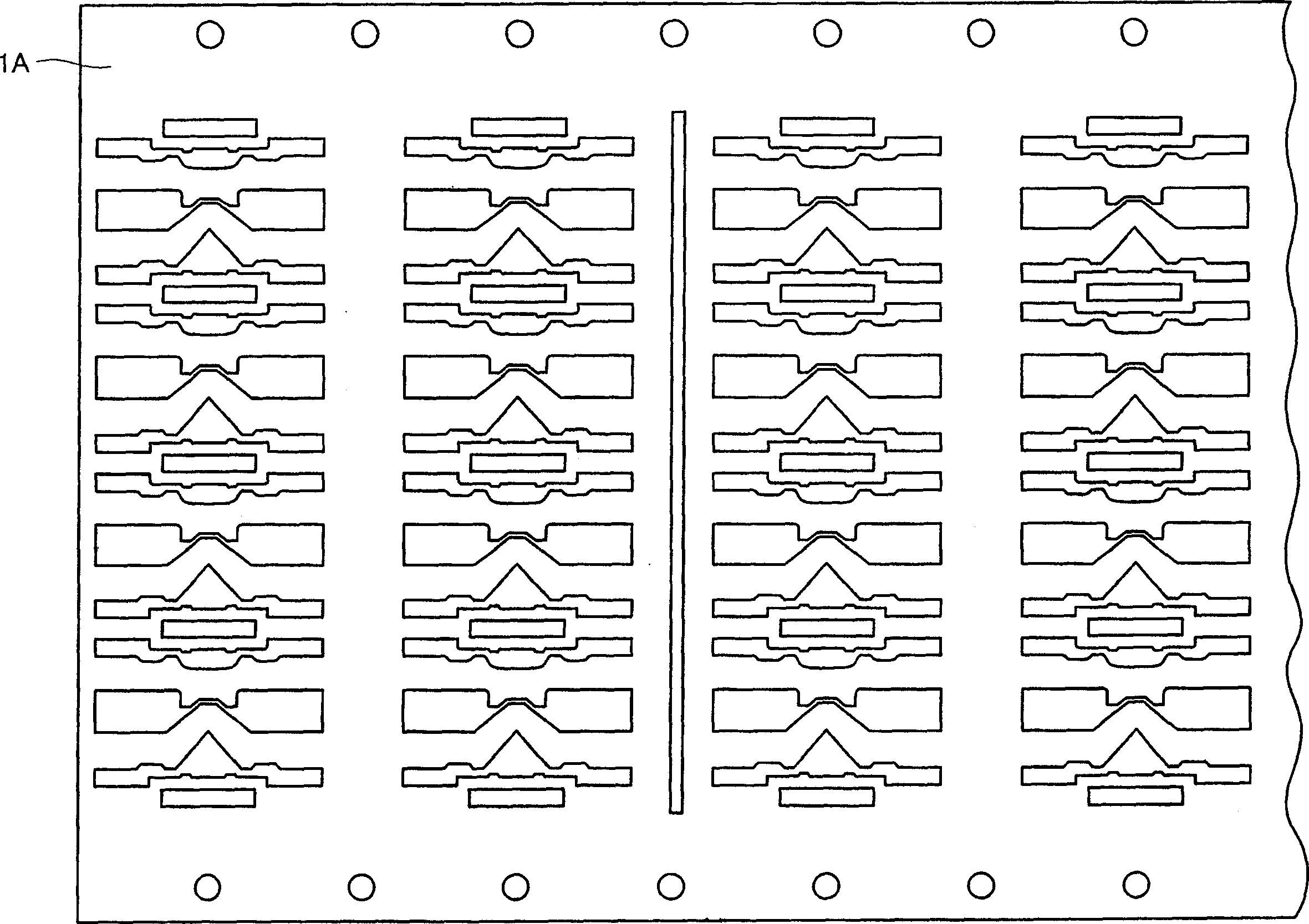

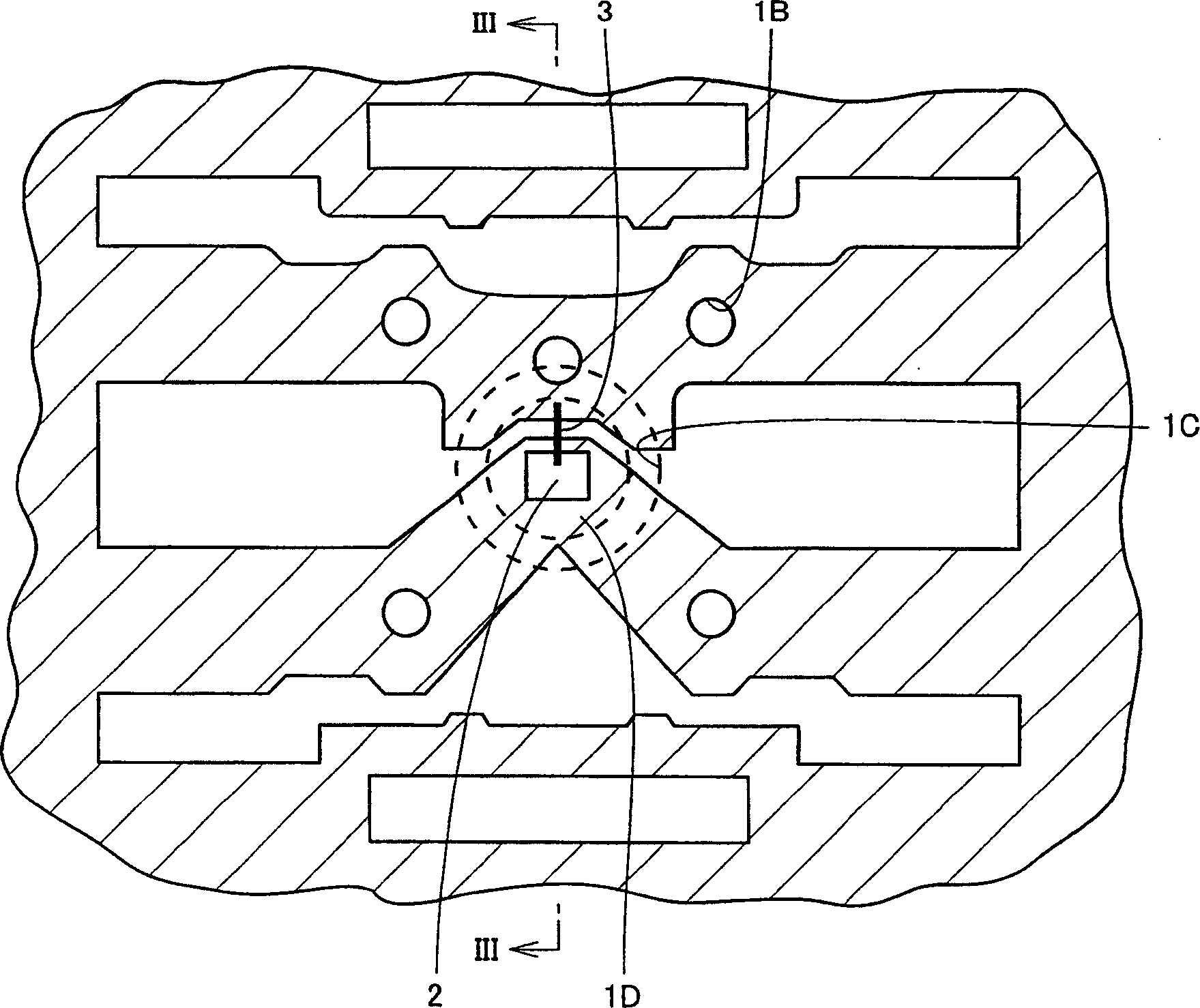

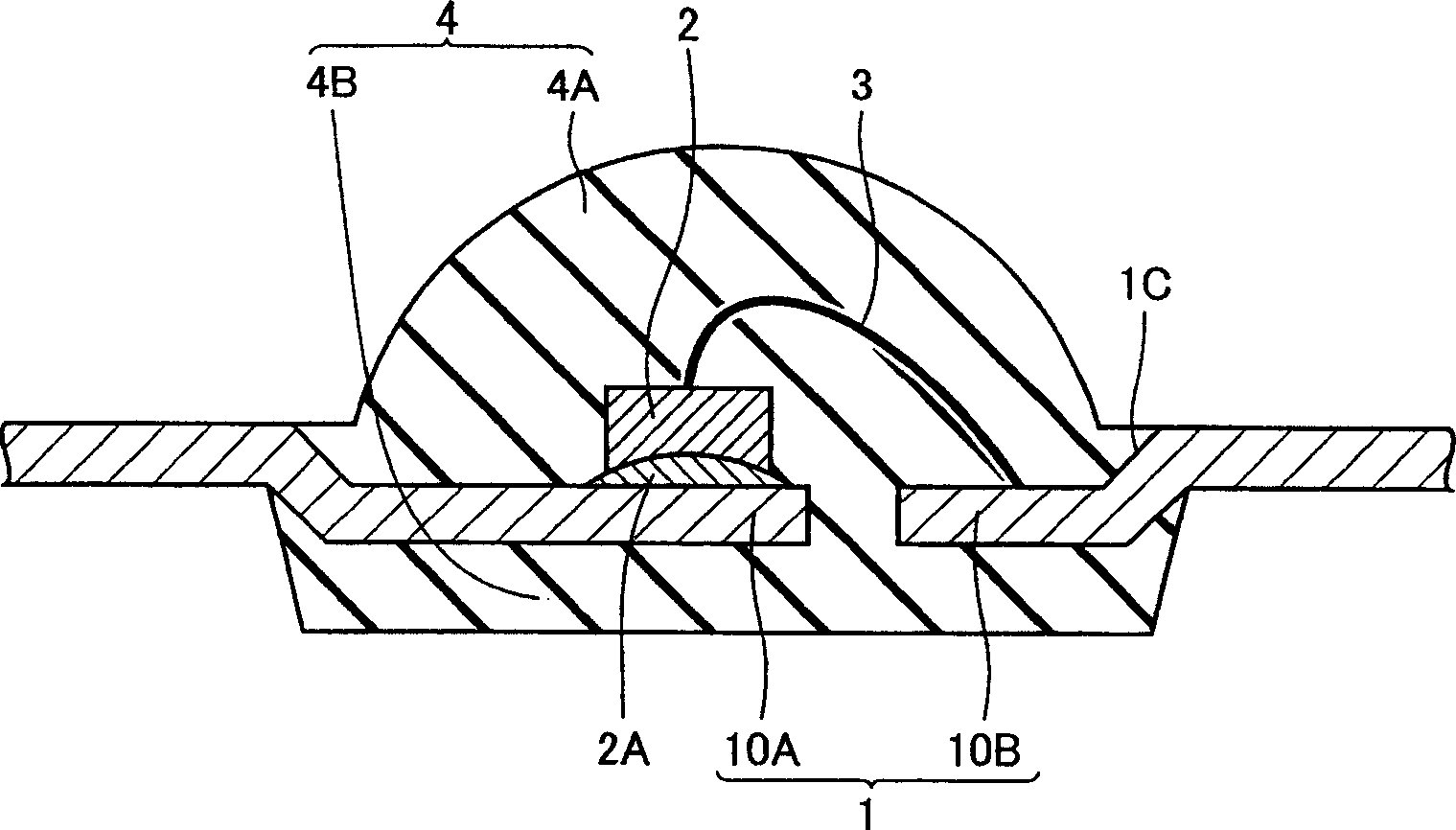

[0037] The following will refer to Figure 1-6 Embodiments of the semiconductor light emitting device and its manufacturing method according to the present invention will be described.

[0038] refer to Figure 5 , the semiconductor light emitting device according to the embodiment of the present invention includes: LED element 2 (semiconductor light emitting element); lead frame 10A (first lead frame) on which LED element 2 is mounted; lead wires electrically connected to LED element 2 through wiring 3 Frame 10B (second lead frame); transparent resin 4 (light-transmitting resin) formed on LED element 2 and lead frame 1 (10A, 10B); and light-shielding resin 7 (blocking resin) Light resin), and surround the periphery of the LED element 2. The transparent resin 4 includes a lens portion 4 and a holding portion 4B holding the lead frame 1 , wherein the lens portion 4A constitutes a lens on the LED 2 .

[0039] The front end of lead frame 1 is inserted into transparent resin 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com