Register sensor

A technology of sensors and registration marks, applied in the field of registration sensors, can solve problems such as deviation, color separation cannot be accurately overprinted and registered with each other

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

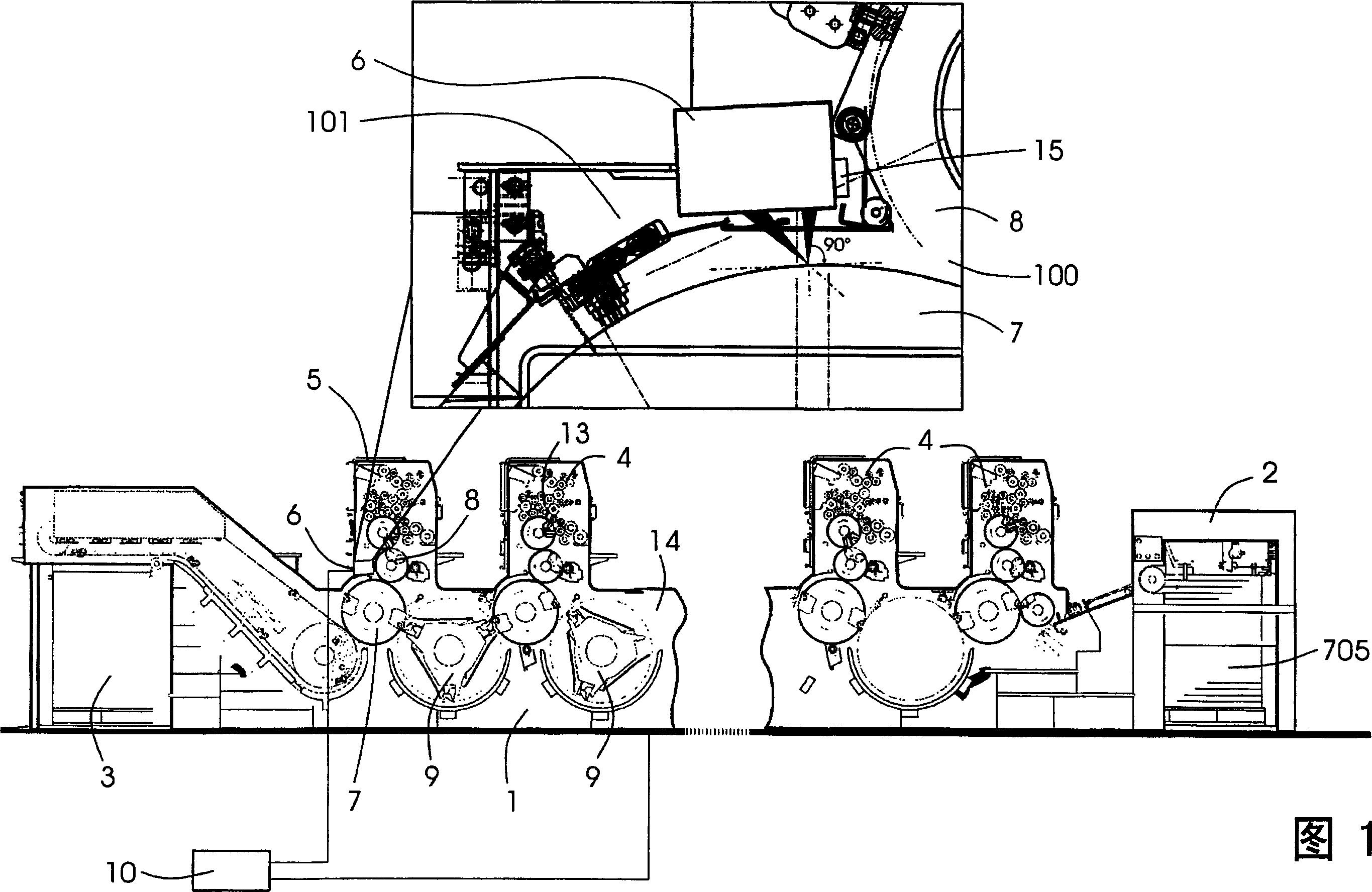

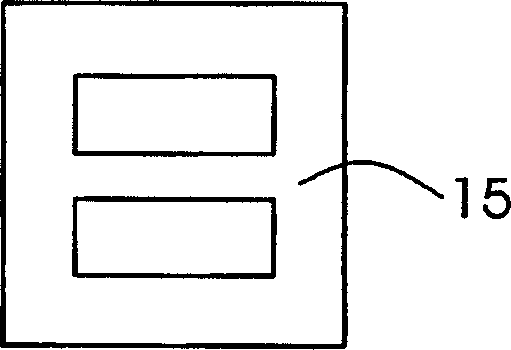

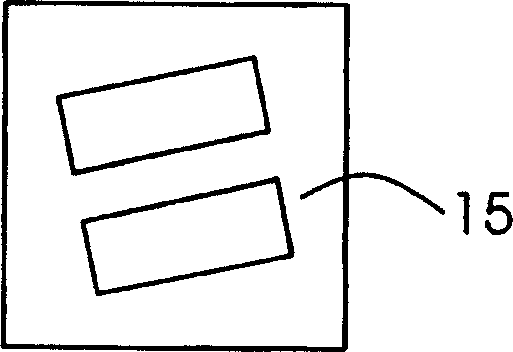

[0028]The printing press 1 in FIG. 1 is a sheet-fed rotary printing press with a feeder module 2 for feeding printed sheets 705 from a sheet stack into the printing press 1 and a take-up unit at the other end of the printing press 1. The paper container 3 is used for stacking the printed sheets 705 after printing. In between, there are four printing units 4 , 5 in FIG. 1 , of which the last printing unit 5 in the direction of conveyance of the printed sheet is equipped with an in-line measuring device. In principle, any number of printing units 4 , 5 is conceivable, wherein the online measuring device does not have to be installed in the last printing unit 5 . The on-line measurement device 6 is mainly used for performing spectrum measurement on the printing control strip on the printed sheet 705 after passing through the printing machine 1, so as to perform automatic color adjustment. In FIG. 1 , two register sensors 15 are arranged on an in-line measuring device 6 having th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com