Ink supplier for ink jet recorder

A technology of ink supply and inkjet recording, applied in printing and other fields, can solve problems such as insensitive liquid level control, complex cost of control devices, and existing problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] By referring to the accompanying drawings representing ideal embodiments of the present invention and studying the following detailed description and claims, the above-mentioned and other objects, features, advantages and methods of realization of the present invention can be clarified, and the present invention can be well understood. invention.

[0026] First, a first embodiment of the present invention will be described.

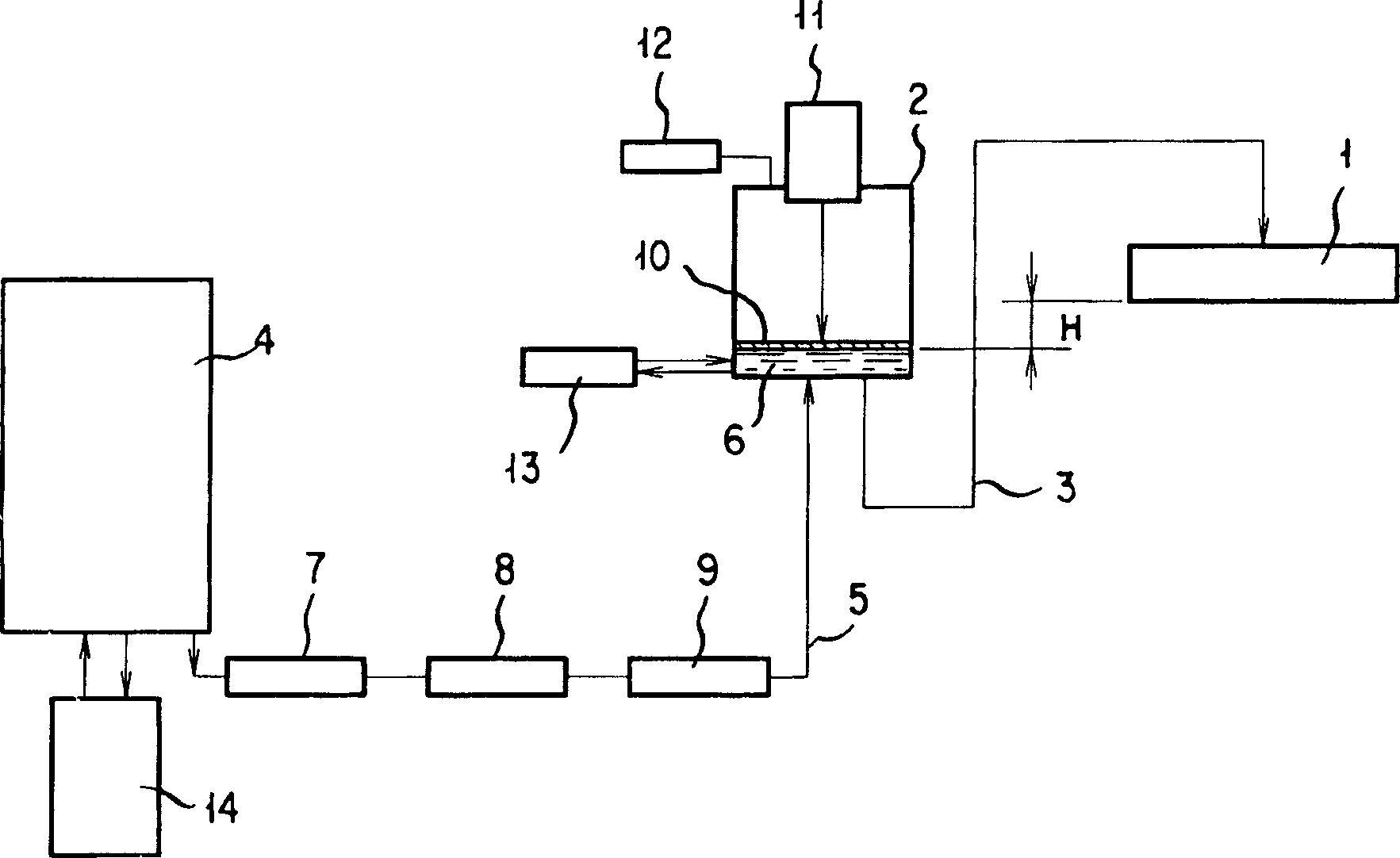

[0027] figure 1 It is an explanatory diagram schematically showing the ink supply system of the ink supply device of the inkjet recording apparatus of the present invention.

[0028] figure 1 Among them, 1 is the recording head of the inkjet recording device, 2 is the sub-tank connected to the recording head 1 through the ink supply tube 3, and 4 is the main tank connected to the sub-tank 2 through the ink supply tube 5. On the ink supply pipe 5 connecting the main tank 4 and the sub tank 2, an ink supply pump 7, a filter 8 and a solenoid valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com