Transparent film mother material and its preparation process

A transparent film and masterbatch technology, which is applied in the field of transparent film masterbatch and its preparation, can solve the problems of decreased transparency, reduced cost, and decreased mechanical properties, and achieve the effects of increasing production and reducing costs

Active Publication Date: 2005-11-09

上海心尔新材料科技股份有限公司

View PDF0 Cites 38 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] The purpose of the present invention is to solve the problem that not only the mechanical properties of the plastic film decrease after using the filler masterbatch, especially the light transmittance, but also the transparency. Good light transmittance, high transparency, and can greatly reduce costs

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0059]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

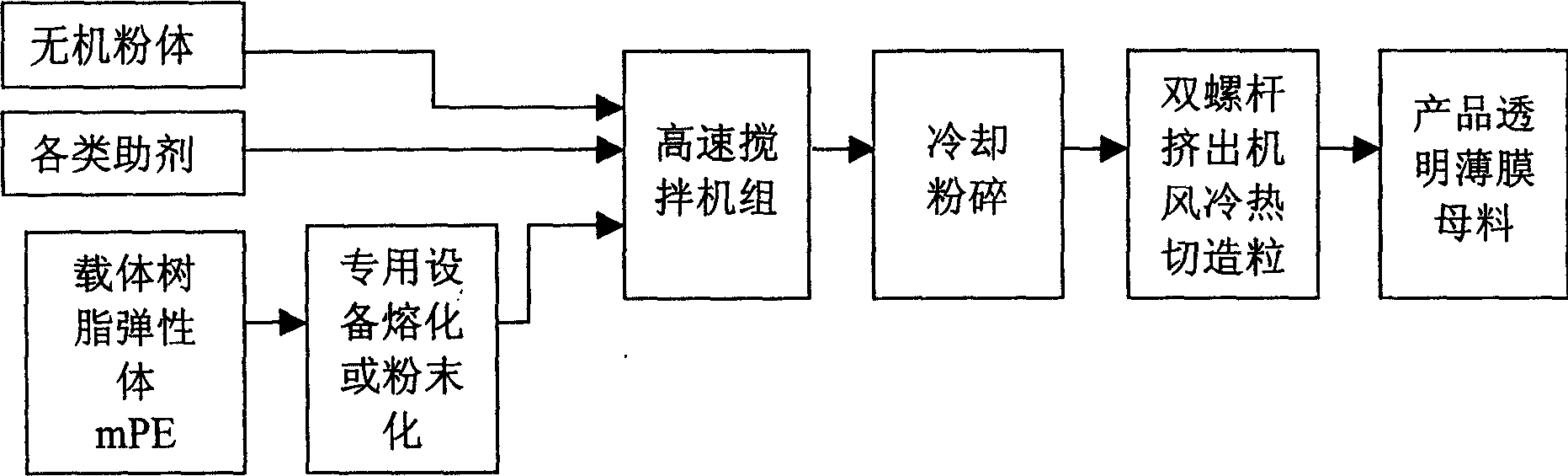

A mother material for transparent film is prepared proportionally from inorganic powder, composite resin as carrier, lubricant, composite coupling agent, and disperser through fusing or powdering the composite resin, coating the surface of inorganic particles by disperser, composite coupling agent, thermoplastic elastomer and composite resin sequentially in high-speed mixer, plasticizing, granualting, hot cutting and cooling. It has high mechanical performance, dispersity and optical property.

Description

1. Technical field: [0001] The invention relates to a masterbatch and a preparation method thereof, in particular to a transparent film masterbatch and a preparation method thereof. 2. Background technology: [0002] In China's plastic processing industry, the plastic packaging industry and the agricultural plastic industry are the industries with the largest output. Among them, various and varied plastic films such as packaging films, agricultural land films, and greenhouse films, whether blow-molded or tape-cast, and extended products of films, such as composite films and geocomposites, use a large amount of resin , mainly high-density polyethylene, low-density polyethylene and linear low-density polyethylene. [0003] In the context of rising oil prices, the price of resin has soared, but the price of products cannot be increased, which makes plastic processing enterprises fall into a very difficult situation. How to face the price increase of plastic raw materials, man...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08K9/04

Inventor 刘伯元陈更新王梓刚

Owner 上海心尔新材料科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com