Low thermal resistance plate solar heat collector

A flat-panel solar energy and heat collector technology, which is applied in the field of solar heat collectors, can solve the problems of large thermal resistance and hinder the improvement of thermal efficiency of heat collectors, and achieve the effects of reducing thermal resistance, simple structure, and improved thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

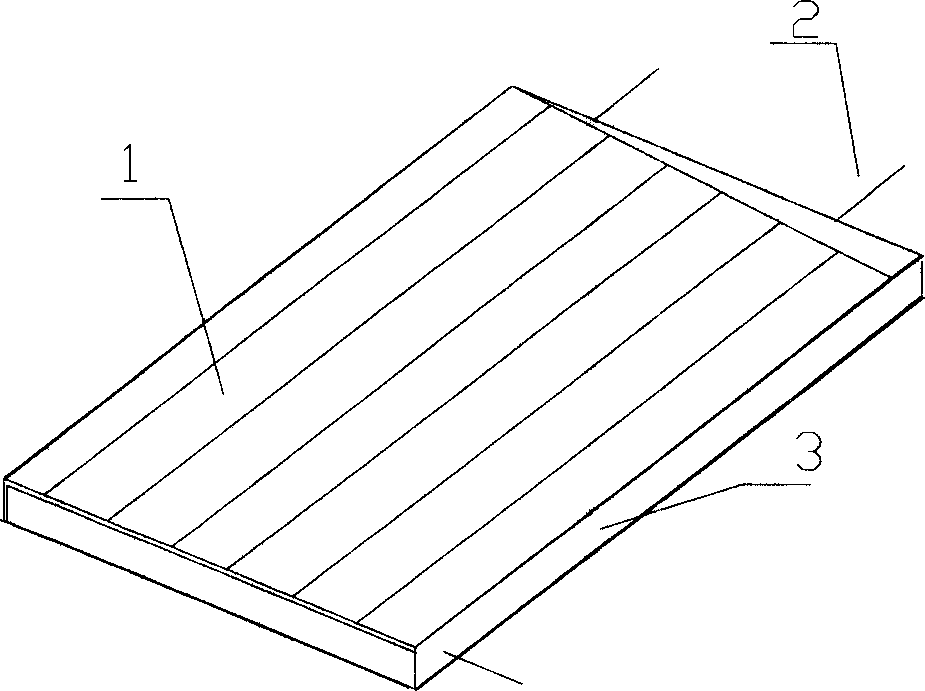

[0011] The present invention is composed of a heat collecting plate 1, a circulating frame 2, and an insulated box 3, the heat collecting plate 1 is welded on the circulating frame 2, and the circulating frame 2 is installed in the insulated box 3.

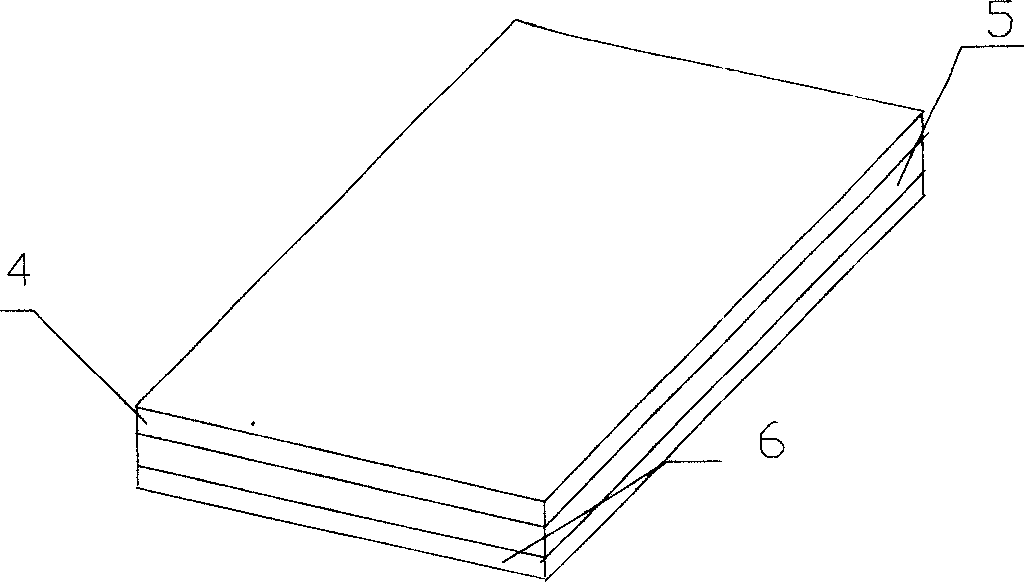

[0012] The heat collecting plate 1 is composed of a selective thick black coating 4 on the upper surface, a metal plate 5 and a selective thin black coating 6 on the lower surface. The role is to improve its heat collection efficiency and reduce heat radiation loss.

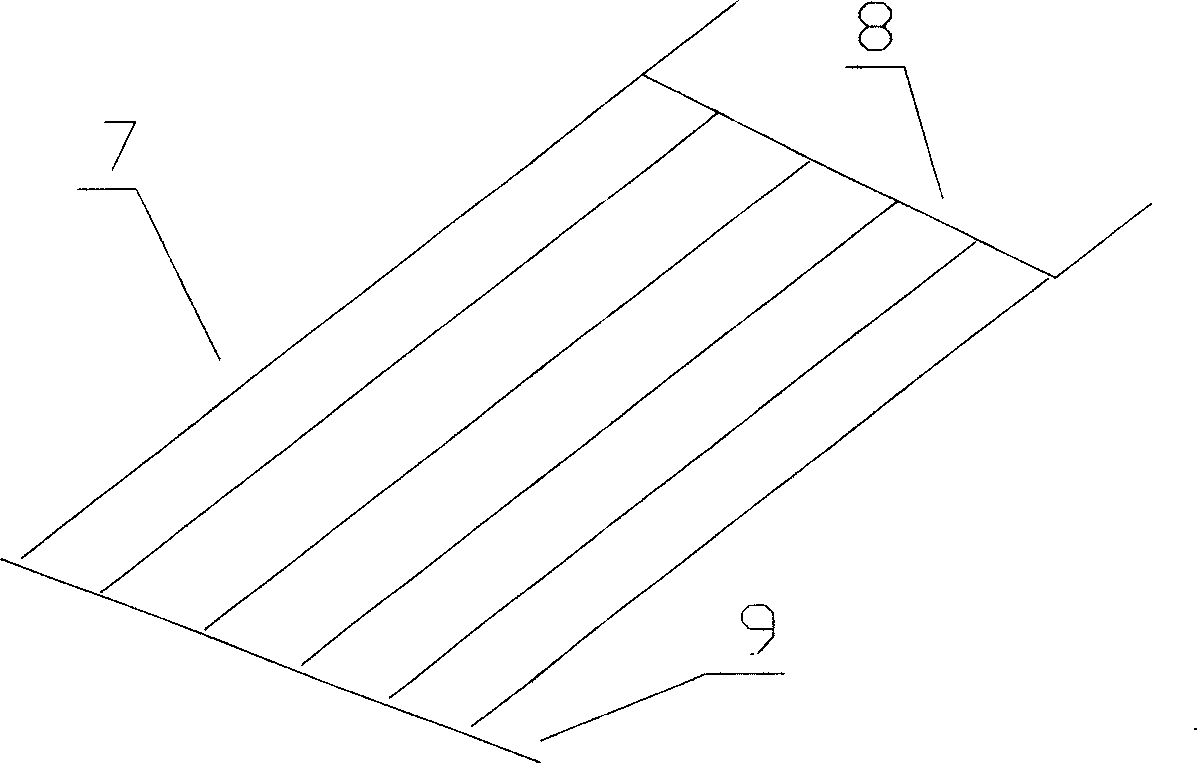

[0013] Circulation frame 2 is made up of heat exchange pipe 7, water collection pipe 8, water inlet and outlet pipe 9, and one end of heat exchange pipe 7 and heat collector plate 1 is welded with water collection pipe 8 at an acute angle; the other end is welded with water inlet and outlet pipe 9 at right angles. The outer surfaces of the water collecting pipe 8 and the water inlet and outlet pipe 9 are all coated with selective black coating.

[0014] Insulation b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com