Backlight module structure

A technology for backlight modules and light-emitting components, which is applied in optics, nonlinear optics, instruments, etc., and can solve problems such as inability to make thinner and larger display panels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

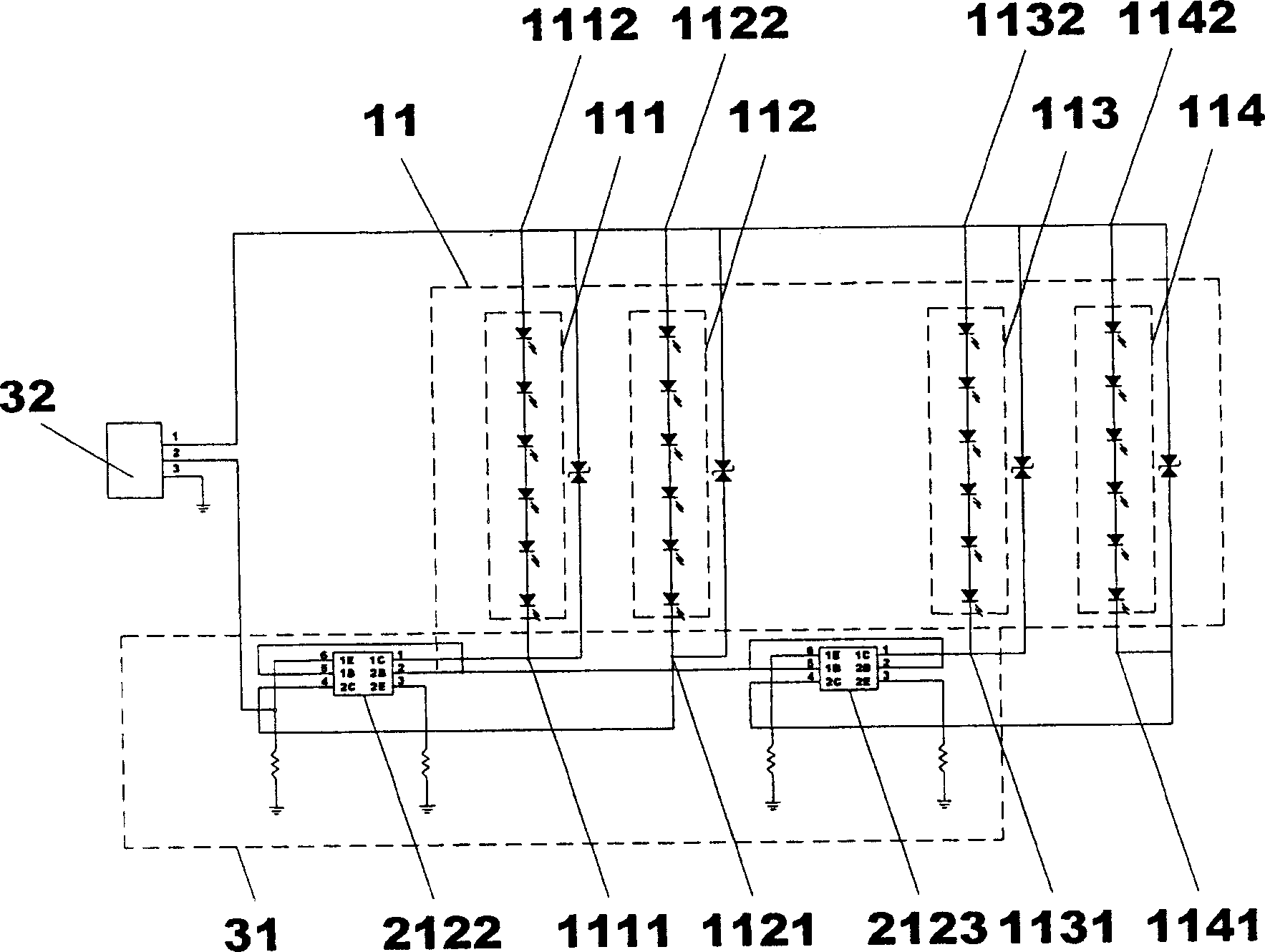

[0048] image 3 It is disclosed that the circuits of the light-emitting component array 11 and its driving circuit structure 31 in the present invention are directly combined. The aforementioned driving circuit structure 31 is composed of two transistor chips 2122 and 2123 . Transistor chip as the known technical number 2122 is used to provide the first series light emitting component 111 and the second series light emitting component 112 by connecting to the first terminal 1111 of the first series light emitting component and the first terminal 1121 of the second series light emitting component The required same current value is used as its control signal connection terminal. In addition, the transistor chip numbered 2123 is connected to the first end 1131 of the third series light emitting element and the first end 1141 of the fourth series light emitting element to provide the third series light emitting element 113 and the fourth series light emitting element 114. The re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com