Identifying heterochrosis of textile fibers and dedicated separation equipment

A technology for textile fibers and special equipment, which is applied in the field of textile fiber heterochromatic identification and separation equipment, can solve the problems of low removal efficiency, unsatisfactory production, and large labor costs, achieving fast separation speed, elimination of image errors, and fine separation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with accompanying drawing, the embodiment of the present invention is described in detail:

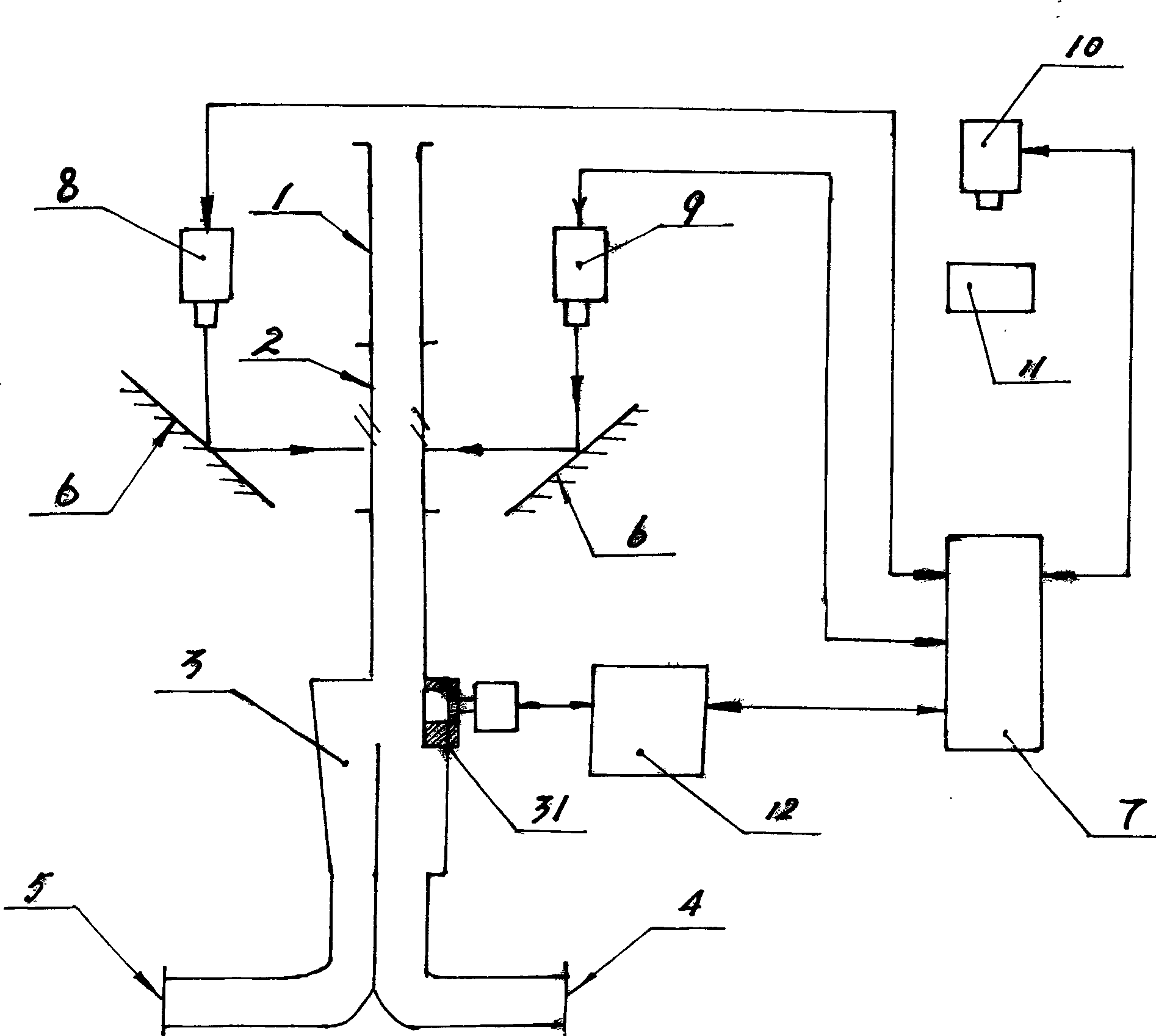

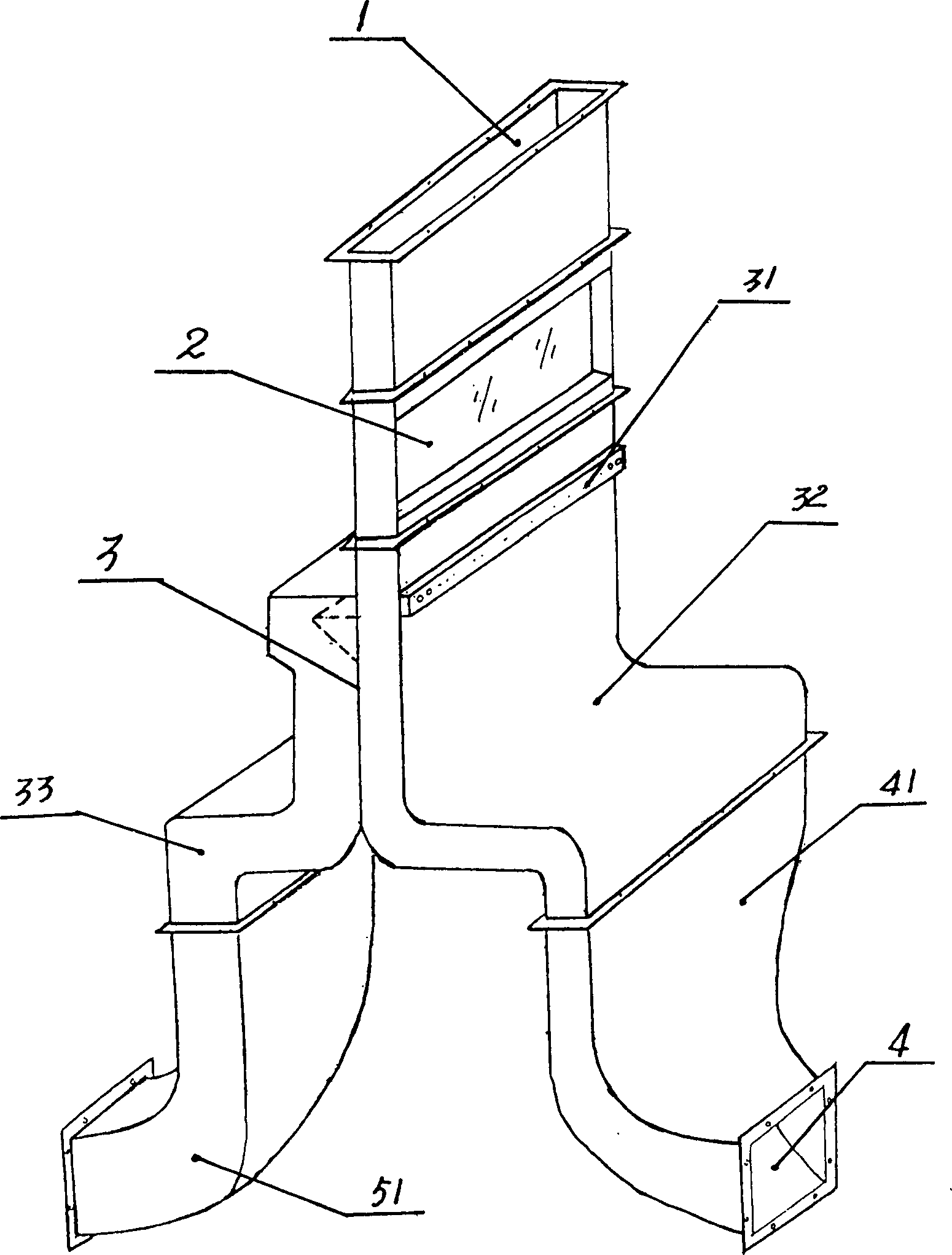

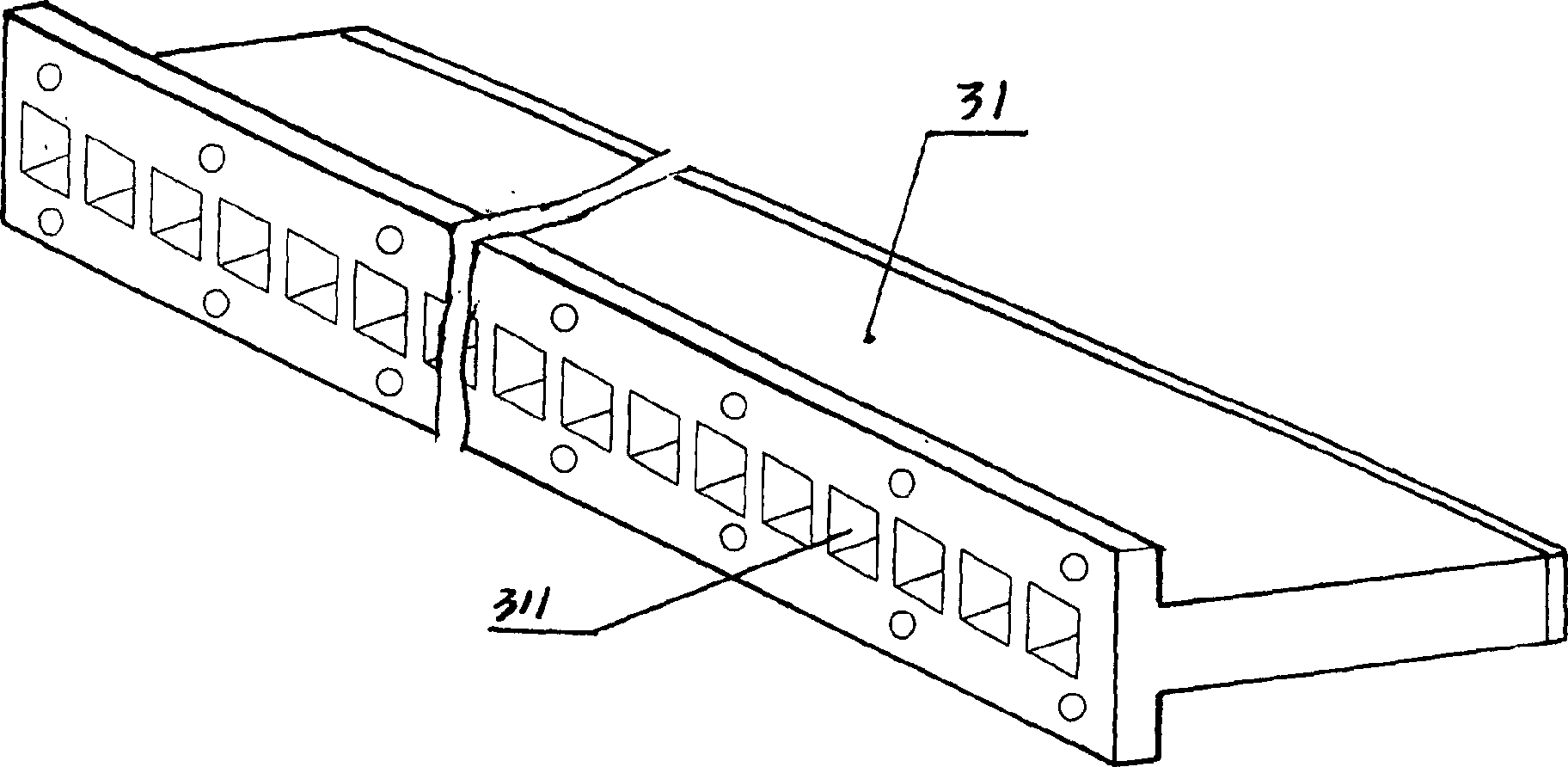

[0013] The special equipment for identifying and separating textile fibers of different colors according to the present invention includes a cotton inflow port 1, a transparent observation window 2, reflectors 6 located on both sides of the transparent observation window 2, a cotton flow camera A8, a cotton flow camera B9, and a sample cotton camera 10 , separation device 3, finished cotton outlet 4, trash cotton outlet 5 and control device 7, transparent observation window 2 is located between cotton inflow inlet 1 and separator 3, trash cotton outlet 5 and finished cotton outlet 4 are located below separator 3 , the two reflectors 6 are installed at an angle of 45 degrees with the transparent observation window 2, the cotton flow camera A8 and the cotton flow camera B9 are located above the reflector 6, and it can observe the cotton flow flowing through the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com