Manufacturing method of group-assorted bulge quantity of angular contacted ball bearing

A processing method and technology of protruding amount, applied in the direction of bearing components, shafts and bearings, metal processing equipment, etc., can solve the problems of low overall efficiency, low production efficiency, complicated and tedious matching process, etc., to improve matching efficiency and improve matching. efficiency, reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

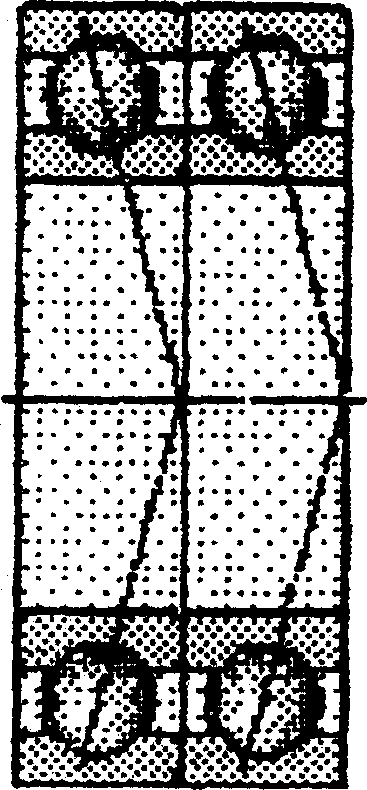

[0037] This embodiment is an arrangement and installation form of paired back-to-back angular contact ball bearings, taking (7004AC / DB as an example), the matching steps of the protrusion amount are as follows:

[0038] 1. Calculate the protrusion δ of the non-reference end of the inner sleeve to the reference end of the outer sleeve

[0039] According to the formula

[0040] δ = δ 0 + δ 1

[0041] = C - ai - ae + 1 / 2 4 g ( R i + Re - Dw ) - g 2 + δ 1

[0042] Substituting...

Embodiment 2

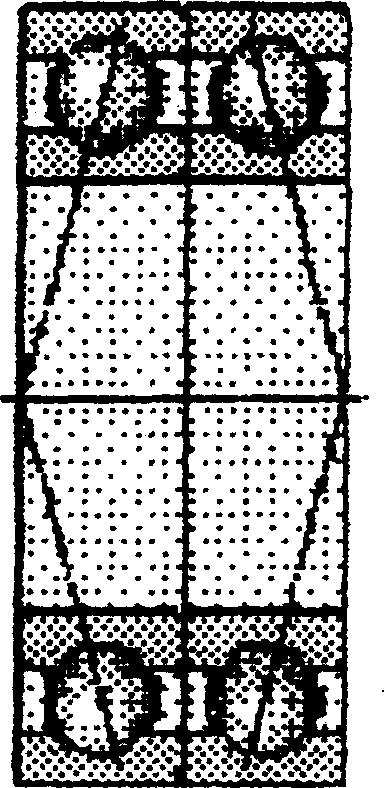

[0056] This embodiment is an arrangement and installation form of paired face-to-face angular contact ball bearings, taking (7004AC / DF as an example), the matching steps of the protrusion amount are as follows:

[0057] 1. Calculate the protrusion δ of the non-reference end surface of the outer sleeve to the reference end surface of the inner sleeve

[0058] Because the single set of 7004AC bearings is exactly the same as Example 1, only the pairing form is different, and the calculation of its protrusion is the same as that of Example 1 (calculation omitted).

[0059] 2. Trial repair of 100 pieces, (repair the non-reference end face of the coat) according to the size of 12 -0.11 -0.12 Grinding, inspection.

[0060] 3. Combine and assemble the ferrules of the trial repair part, measure the protrusion amount, and record the protrusion amount value at the same time.

[0061] 4. Analyze the value and distribution of the protruding amount of the product after the trial repair. ...

Embodiment 3

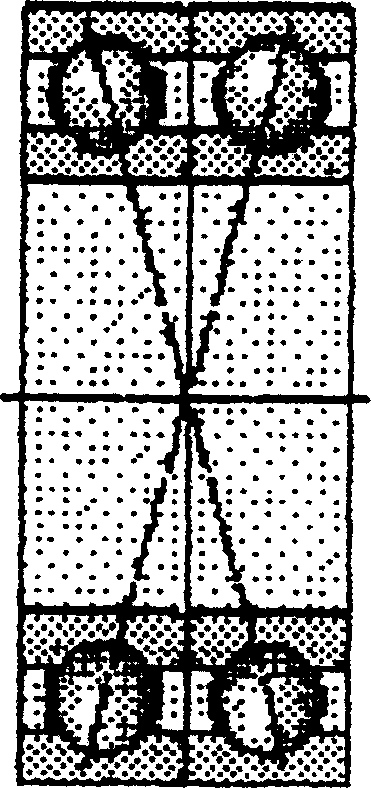

[0065] This embodiment is an arrangement and installation form of paired tandem angular contact ball bearings, taking (7004AC / DT as an example), the matching steps of the protrusion amount are as follows:

[0066] 1. This model is exactly the same as the examples 1 and 2, but the matching form is different, and the calculation of the protrusion amount is slightly

[0067] (calculation with embodiment 1)

[0068] 2. According to its unique matching form, we hope that its protrusion δ may be close to zero, so as to achieve the effect of "universal matching". Therefore, 800 pieces are tried to be repaired, including 400 pieces of inner and outer rings, all of which are non-reference end faces, and the size is 12 -0.09 -0.10 control.

[0069] 3. Combine and assemble the ferrules of the trial repair part, measure the protrusion amount, and record the protrusion amount value at the same time.

[0070] 4. Analyze the value and distribution of product protrusion after trial repair...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com