Movable reed of electromagnetic relay

An electromagnetic relay and moving spring technology, applied in electromagnetic relays, electromagnetic relay details, relays, etc., can solve the problems of many processing steps, low work efficiency, complexity, etc., to eliminate additional resistance and possible existing, improve work Efficiency and stability, the effect of improving the ratio of capacity to volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

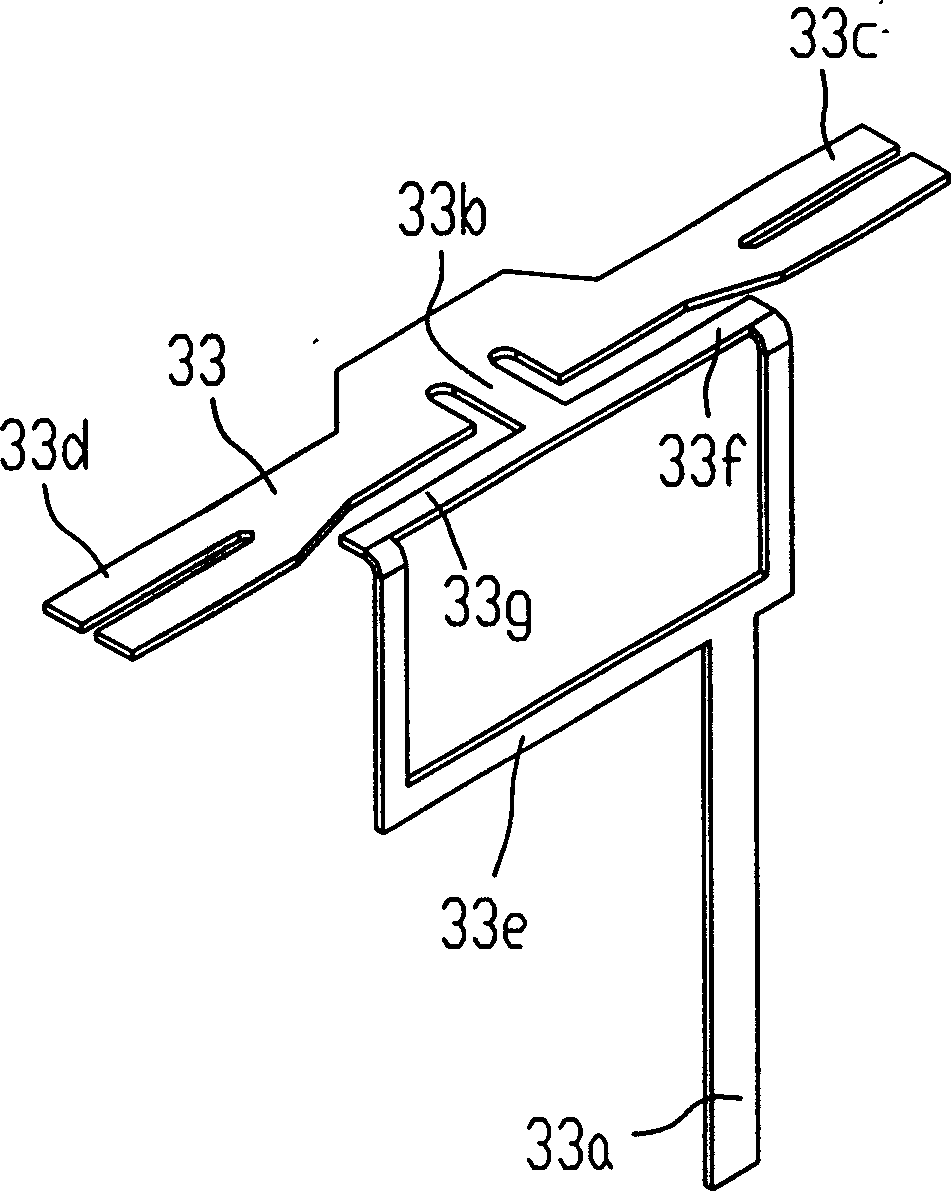

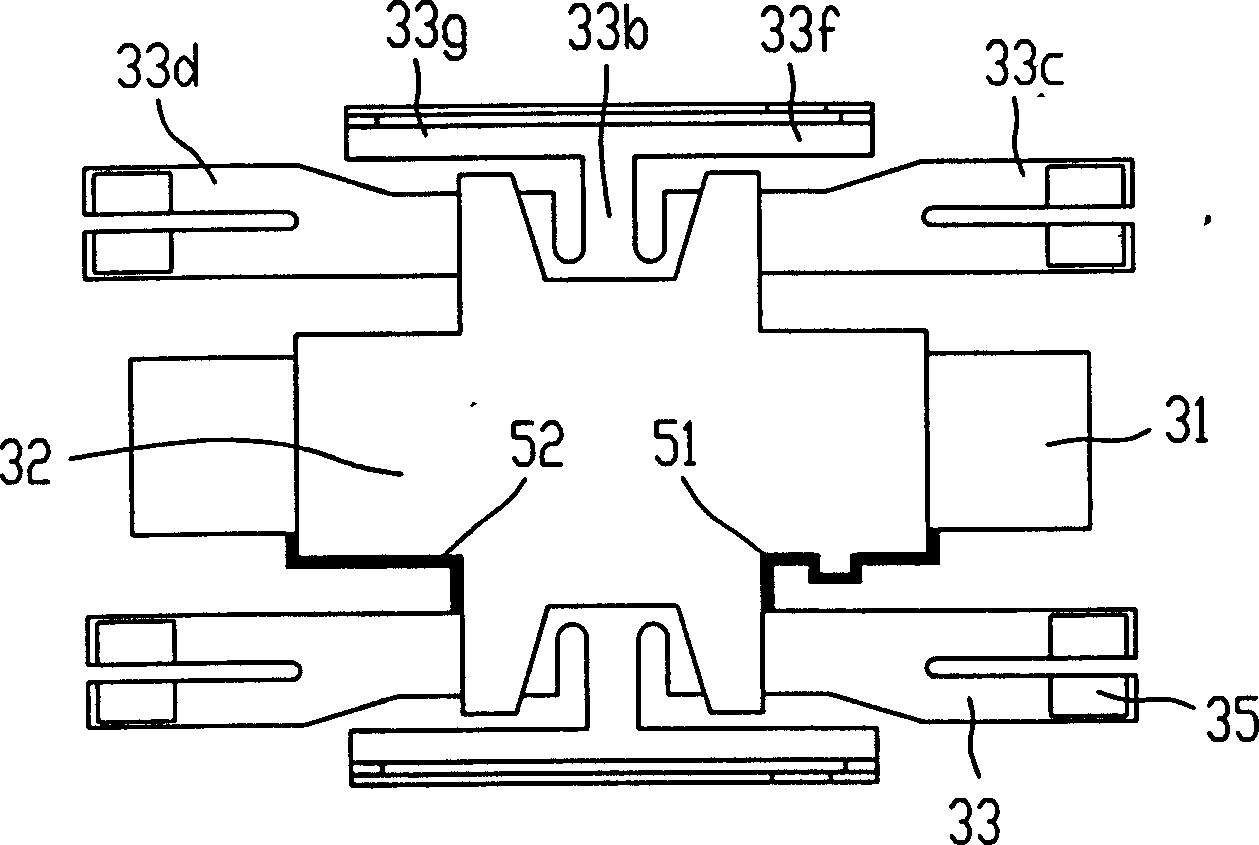

[0015] like figure 1 As shown, the moving spring 33 is an integrated design, including three free ends, one end is the moving spring lead-out pin 33a of the electromagnetic relay, the other two ends are the contact ends 33c, 33d of the moving spring, and connecting parts 33e, 33f, 33g and 33b; two contact ends 33c, 33d and connecting parts 33e, 33f, 33g and 33b of moving spring 33 constitute "work" shape structure; connecting parts 33e, 33f, 33g and 33b of moving spring 33 support moving spring 33, so that both The contact ends 33c and 33d do see-saw movement, and the connecting parts 33e, 33f, 33g and 33b are conductors, so that the relay load is directly transmitted from the contact ends 33c or 33d to the moving spring lead-out pin 33a of the relay, eliminating the need for several The additional resistance produced by the joining of parts.

Embodiment 2

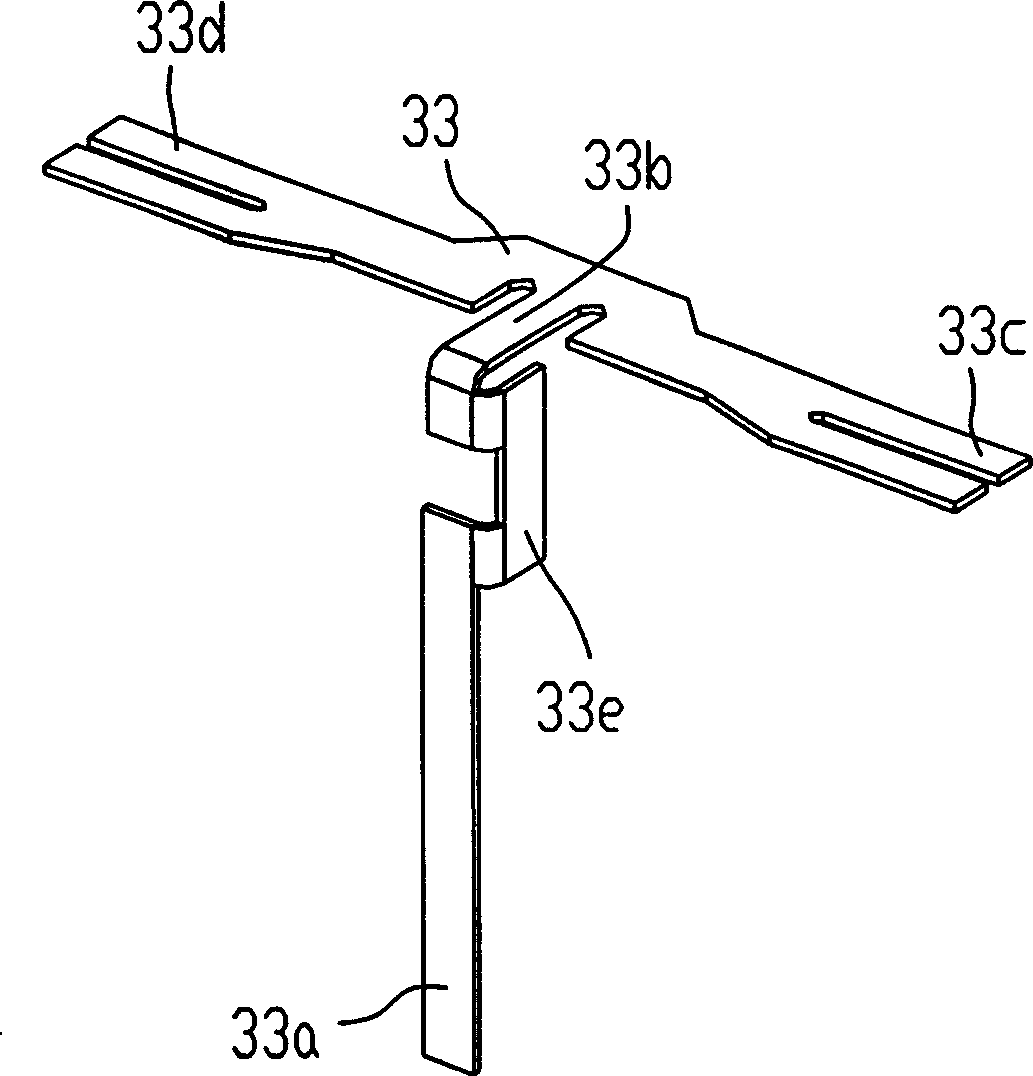

[0017] figure 2 Another embodiment of the moving spring of the present invention is given, the moving spring 33 is integral, including three free ends, one end is the moving spring lead-out pin 33a of the relay, and the other two ends are the contact ends 33c, 33d of the moving spring , also includes connecting portions 33e and 33b; the two contact ends 33c, 33d of the moving spring 33 and the connecting portions 33e and 33b form a “T”-shaped structure. The connecting parts 33e and 33b of the moving spring 33 support the moving spring 33, allowing the two contact ends 33c and 33d to do a seesaw movement, and the connecting parts 33e and 33b are conductors, so that the relay load is directly transmitted from the contact ends 33c or 33d to the relay The movable spring leads out pin end 33a, has eliminated the additional resistance that produces because of several parts joints.

Embodiment 3

[0019] like figure 1 and figure 2 As shown, the contact ends 33c, 33d of the moving spring 33 are in the shape of "匚"; the two contact ends 33c, 33d of the moving spring 33 are welded with contacts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com