Oxygen sensor

An oxygen sensor and protector technology, applied in the field of oxygen sensors, can solve the problems of difficulty in improving durability, reliability, cracking of detection elements, and inability to fully prevent condensed water from immersing in

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

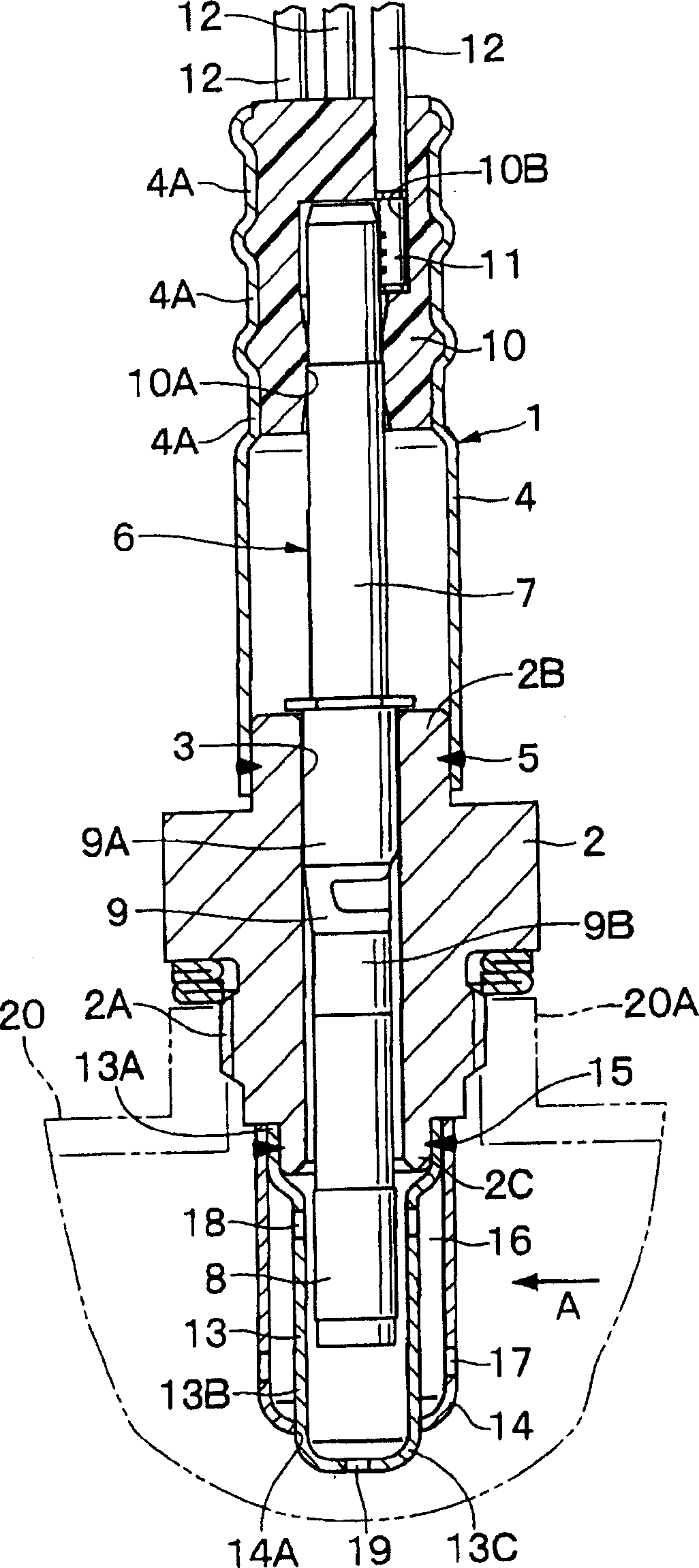

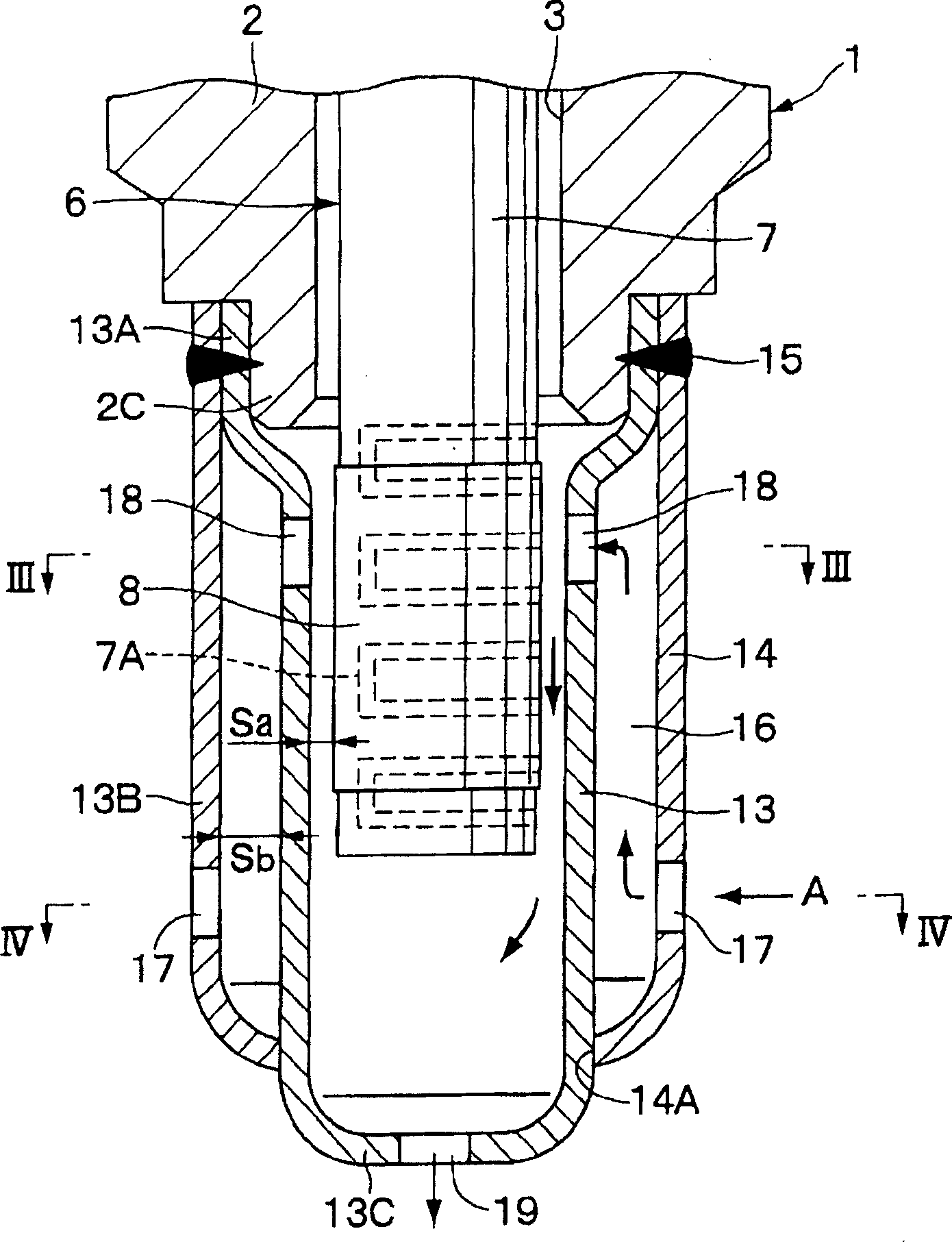

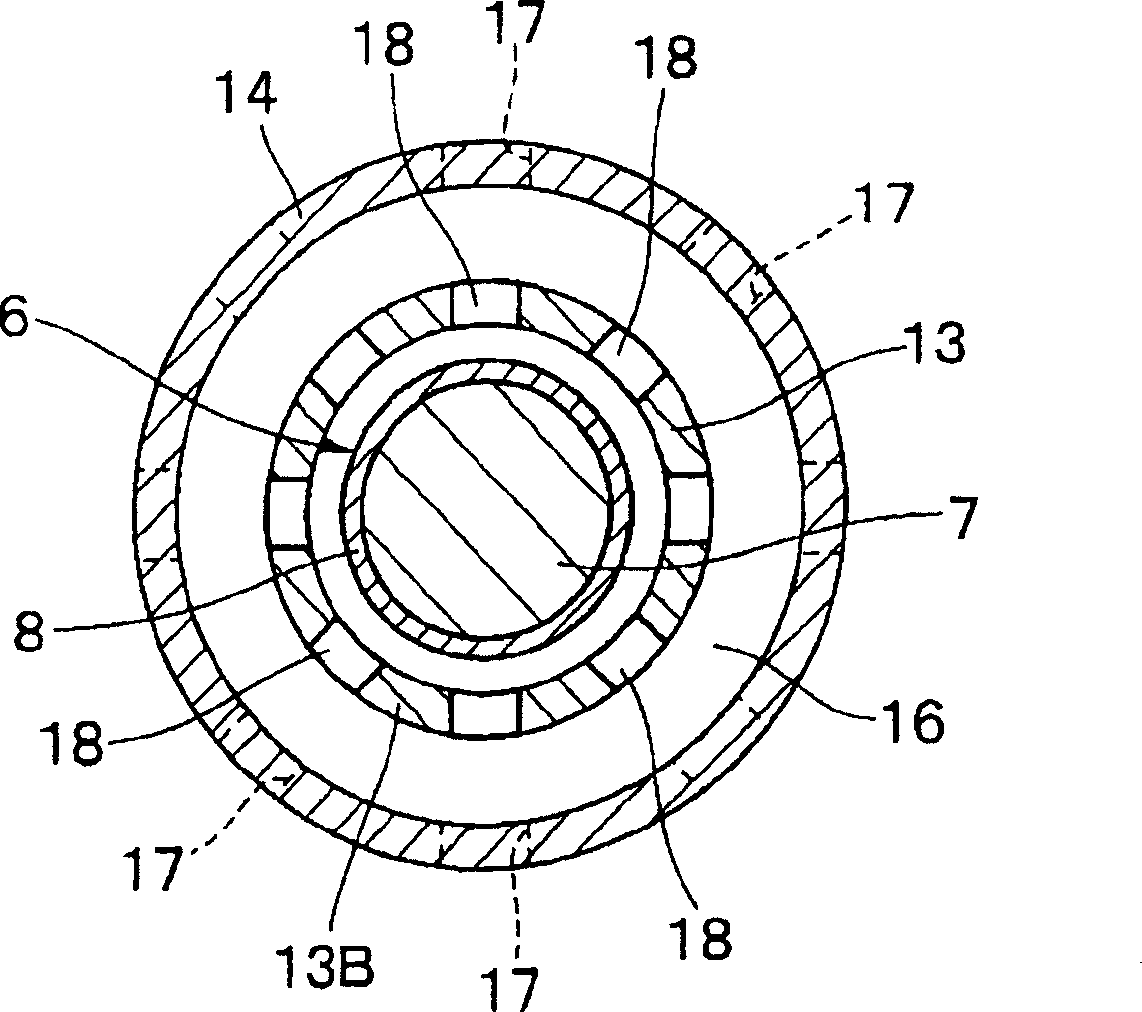

[0029] Next, an oxygen sensor for detecting the concentration of oxygen contained in exhaust gas of a vehicle as an embodiment of the present invention will be described in detail with reference to the drawings.

[0030] In the figure, 1 is a casing constituting the outer shell of the oxygen sensor. The casing 1 is made of a metal material, for example, into a stepped cylindrical shape, and is composed of a seat member 2 and a cover member 4 which will be described later.

[0031] 2 is a step-shaped cylindrical seat member constituting the front end side of the housing 1. The seat member 2 is made of a metal material such as steel and is formed on its outer peripheral side to be screwed to the exhaust pipe 20 side to be described later. Threaded part 2A. Furthermore, in the seat member 2 , a cylindrical cover member fitting portion 2B is formed on the bottom end side thereof, and a cylindrical protector fitting portion 2C is formed on the front end side thereof. In addition, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com