Anchoring bolt for securing thermal insulation plate onto wall

A technology for thermal insulation boards and anchor bolts, applied to structural elements, building components, building reinforcements, etc., can solve the problems of damage and fracture at the joint between the outer end cap and the bolt sleeve, and the easy damage and fracture of anchor bolts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

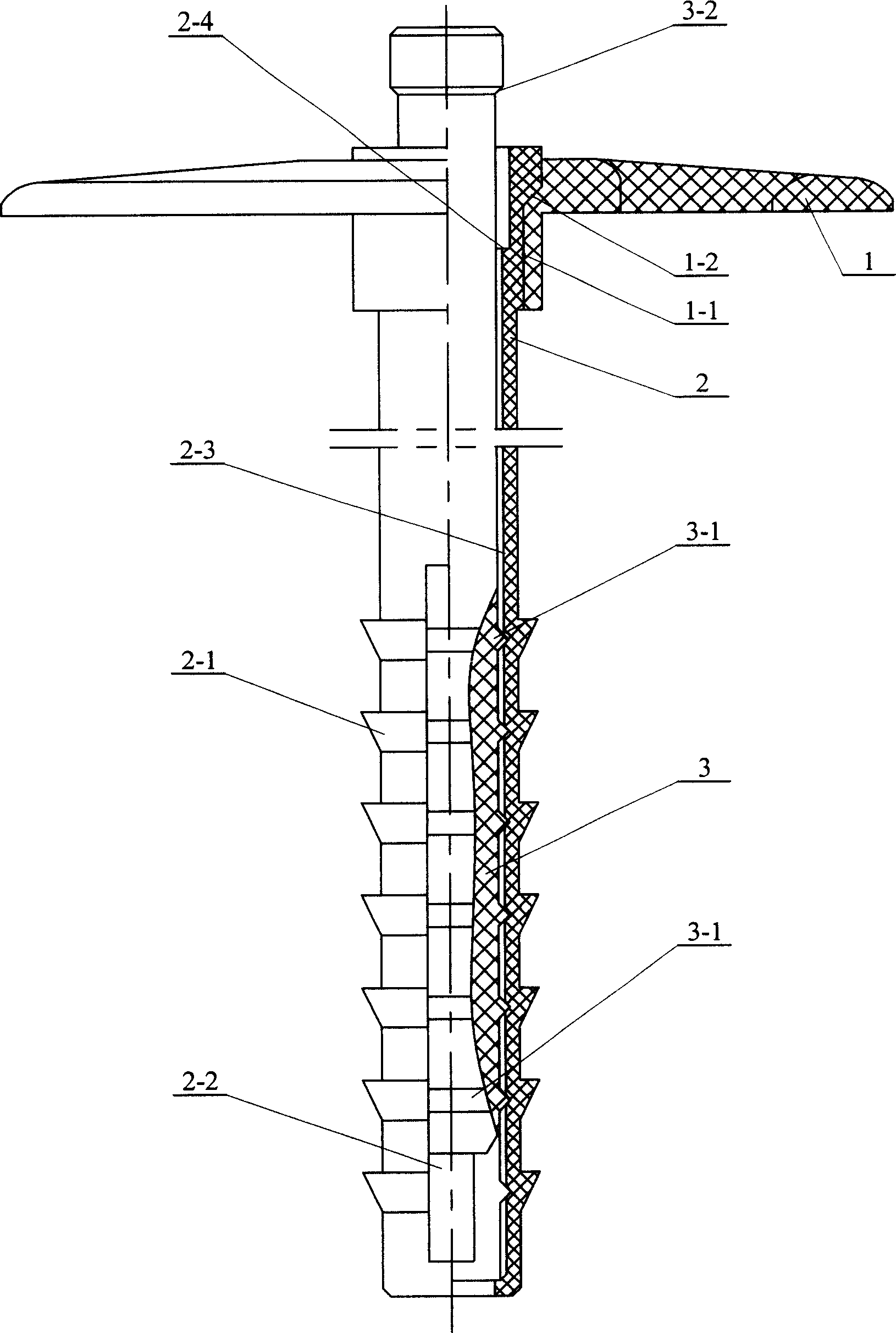

[0005] Specific implementation mode one: the following combination figure 1 Describe this embodiment in detail, this embodiment is made up of end cap 1, bolt sleeve 2 and core rod 3; The end diameter 1-1 is matched and connected, and is axially positioned by the upper end step of the bolt sleeve 2 and the counterbore end face 1-2 at the upper end of the end cap 1. There are multiple surrounding raised bands 3-1 at the lower part of the core rod 3, and the bolt sleeve 2 The outer surface of the lower part has multiple surrounding inverted cone raised bands 2-1, and the lower part of the bolt sleeve 2 has two axially long openings 2-2 which are symmetrical through the pipe wall of the bolt rod. Surrounding the reverse cone raised band 2-1 is evenly distributed on the bolt sleeve 2 at the long opening 2-2. All the parts of the present invention are molded by mold injection using thermoplastic polypropylene material.

specific Embodiment approach 2

[0006] Embodiment 2: In this embodiment, the outer conical step surface 3-2 at the upper end of the core rod 3 is in contact with the inner counterbore step 2-4 at the outer end of the upper end of the bolt sleeve 2 for positioning.

[0007] The installation process of the present invention is as follows: first, the outer surface of the lower part of the bolt sleeve 2 has a plurality of surrounding inverted cone raised bands 2-1 and a bolt end with two symmetrical axially long openings 2-2 penetrating through the wall of the bolt sleeve 2, Penetrate through the inner hole of the outer flat end of the end cap 1, and then pass the lower end bolt sleeve 2 that has penetrated into the end cap 1 through the installation hole of the insulation board and install it into the inner hole of the wall for installation. When the lower end cap 1 When the end face is positioned by the end step of the bolt sleeve 2 and the end face 1-2 of the upper end counterbore of the end cap 1 to achieve a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com