Lens module fixing arrangement and method

A lens module and fixed structure technology, applied in installation, optics, instruments, etc., can solve the problems of increased manufacturing cost, decreased product mass production, and inability to achieve fixed effects, etc., achieving easy implementation, simple structure, and avoiding the focus position Staggered effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

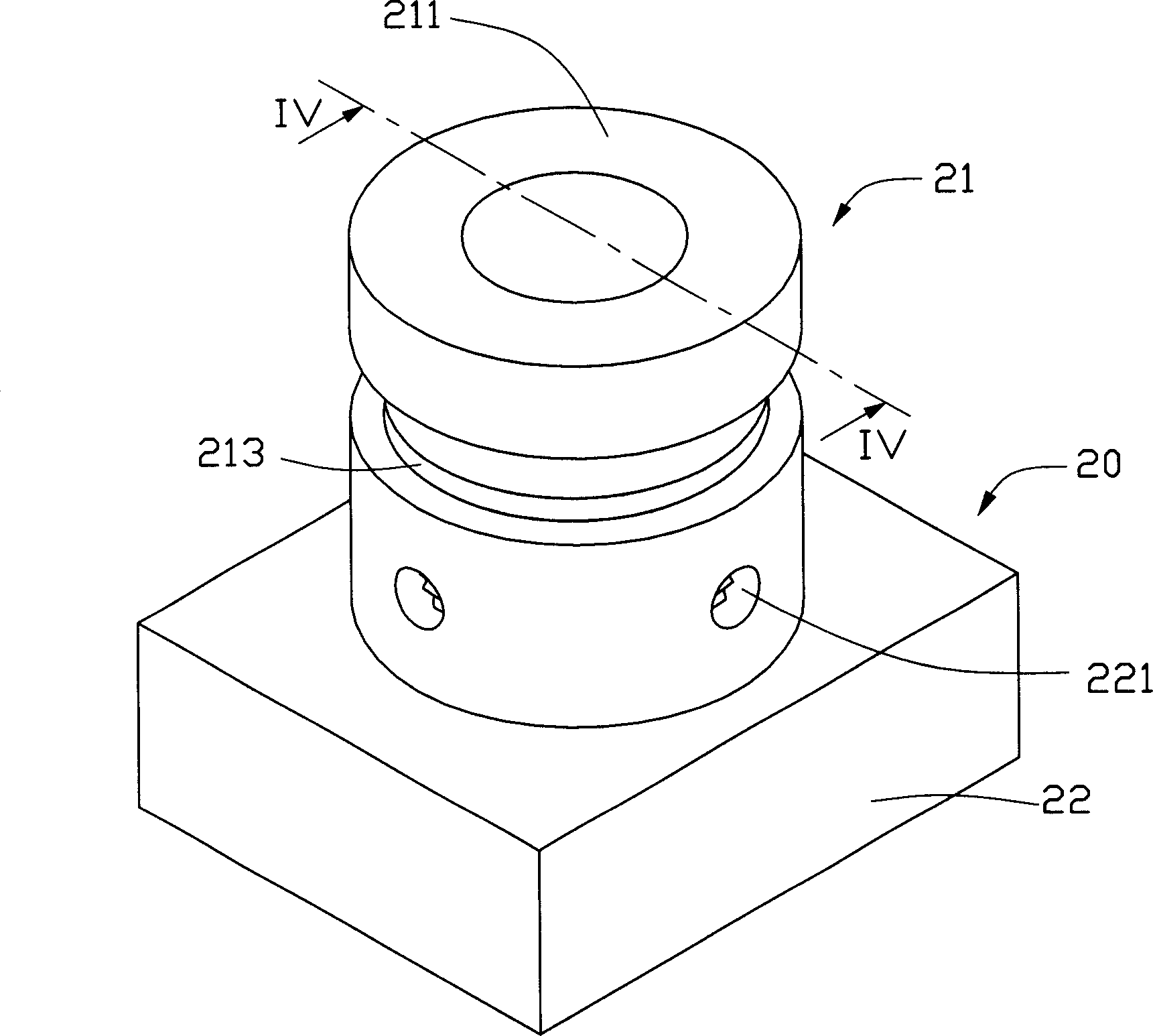

[0014] Please refer to image 3 , Figure 4 and Figure 5 , the lens module fixing structure 20 of the present invention includes a lens module 21 and a lens holder 22, wherein the lens module 21 is composed of a lens barrel 211 and a plurality of lenses 212, etc., and the lens holder 22 includes a peripheral wall (not marked). The outer wall of the barrel 211 and the inner wall of the lens holder 22 are respectively tapped with a certain length of thread (not marked), and there is an annular dispensing groove 213 on the outer wall of the lens barrel 211. The annular dispensing groove 213 is mainly used for the final heat curing treatment. Accommodate the heat-curing glue, so that the heat-curing glue can fully contact the lens barrel 211 and the lens holder 22, thereby achieving a better bonding effect. In addition, several holes 221 are provided on the peripheral wall where the lens holder 22 and the lens barrel 211 are joined. Usually 4, and symmetrically distributed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com