Method and device for the disintegration of especially inorganic materials

A technology of inorganic materials and working surfaces, applied in grain processing and other directions, can solve problems such as insufficient activation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

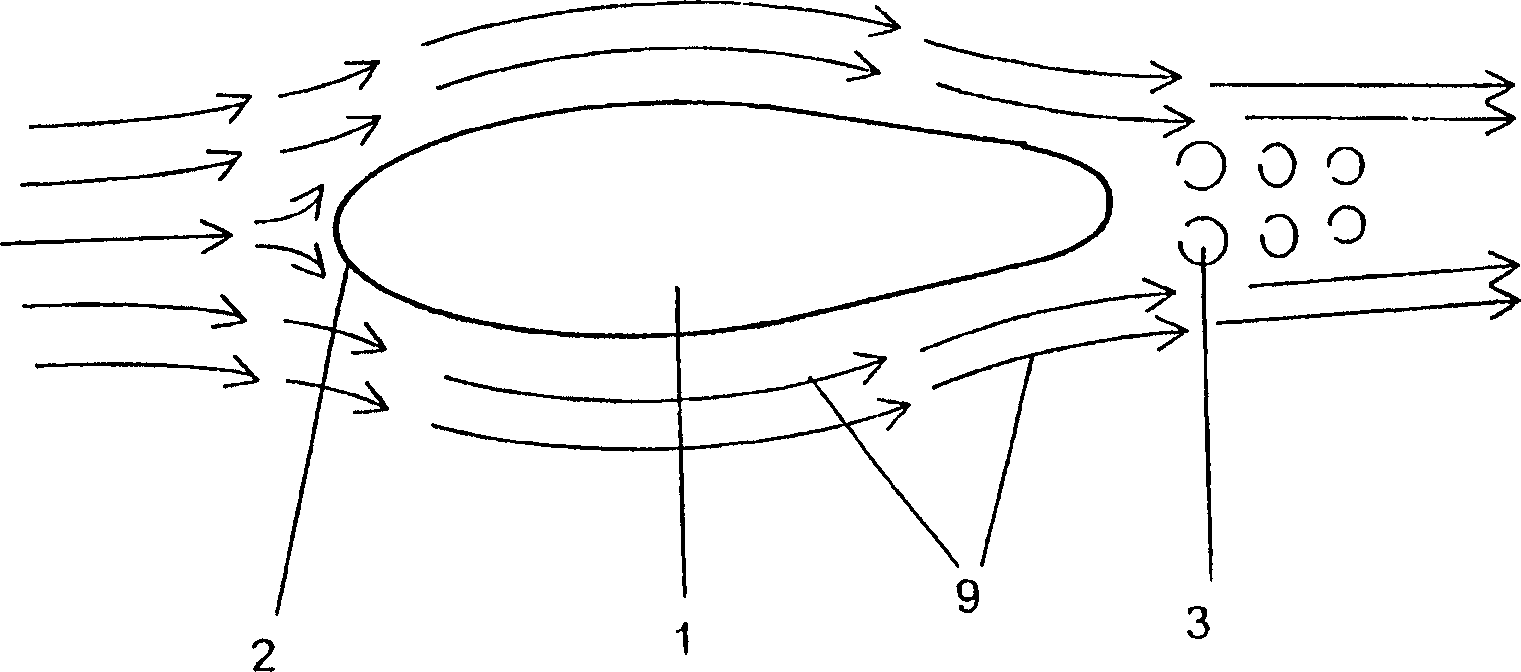

[0024] Figure 1a Firstly, a molded body 1 of typical design is shown together with flow lines 9 in the subsonic range. The flow lines 9 first flow around the cross section of the fluid 1 , wherein, depending on the cross section of the molded body 1 , the laminar flow can be interrupted and eddies 3 occur in the rear region of the molded body 1 .

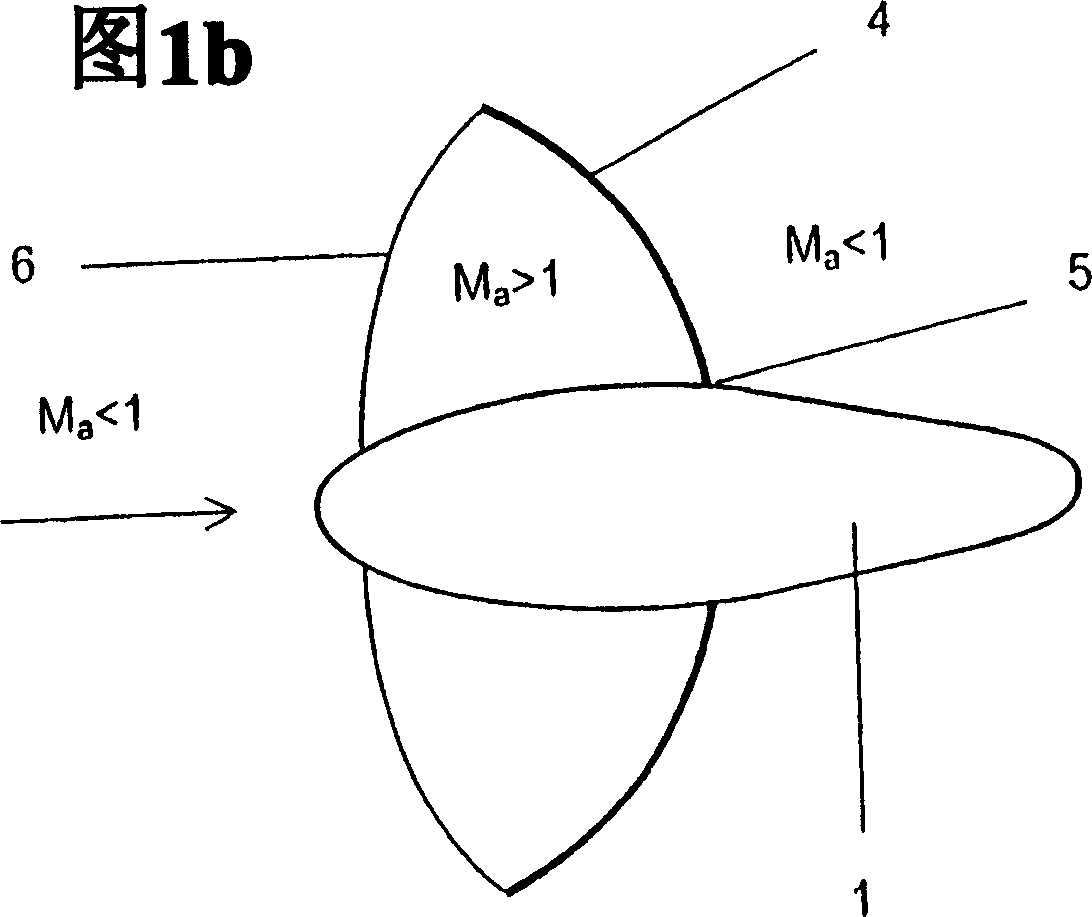

[0025] Figure 1b shows the speed ratio in the so-called supersonic speed range. A region is formed in relation to the surface of the molded body 1 in which the relative velocity of the surrounding air locally reaches supersonic velocity. This region is marked with "Ma > 1" in Fig. 1b. This area is in turn bounded by the shock pressure working face 4 with a short pressure rise and a final pressure drop. Point 5 marks the location of the in particular mechanical load on the upper surface of the molded body 1 .

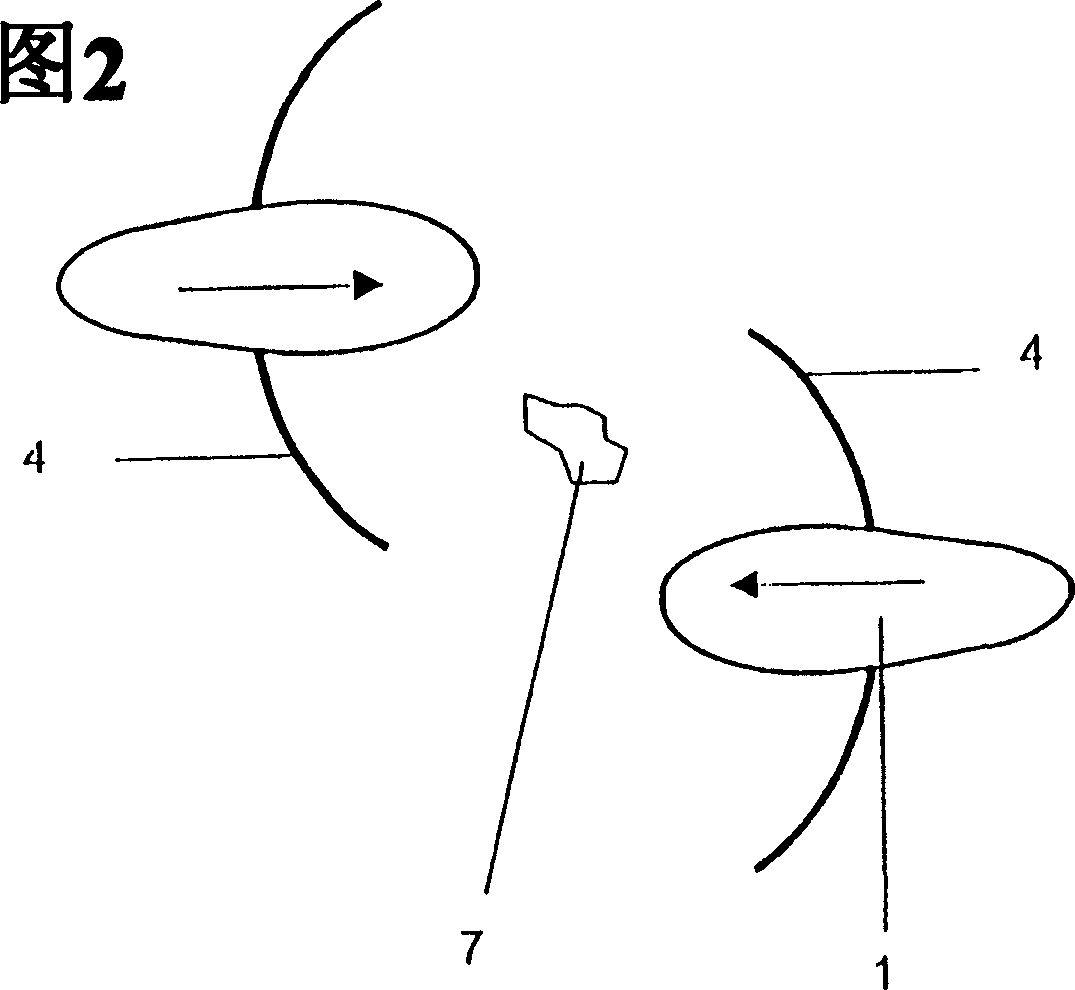

[0026] FIG. 2 shows the impact pressure of the working surface 4 on the particles 30 . The particles 30 alternately pas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com