Pb-Ba bimetal MOFs as well as preparation method and application thereof

A bimetallic and reaction solvent technology, applied in the fields of Ba bimetallic MOFs, bimetallic MOFs, preparation, and Pb, can solve the problems of weak catalytic ability, uneven catalyst dispersion, affecting the thermal decomposition of propellant components, etc., to reduce the pressure. Exponential, easy industrial production, high yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

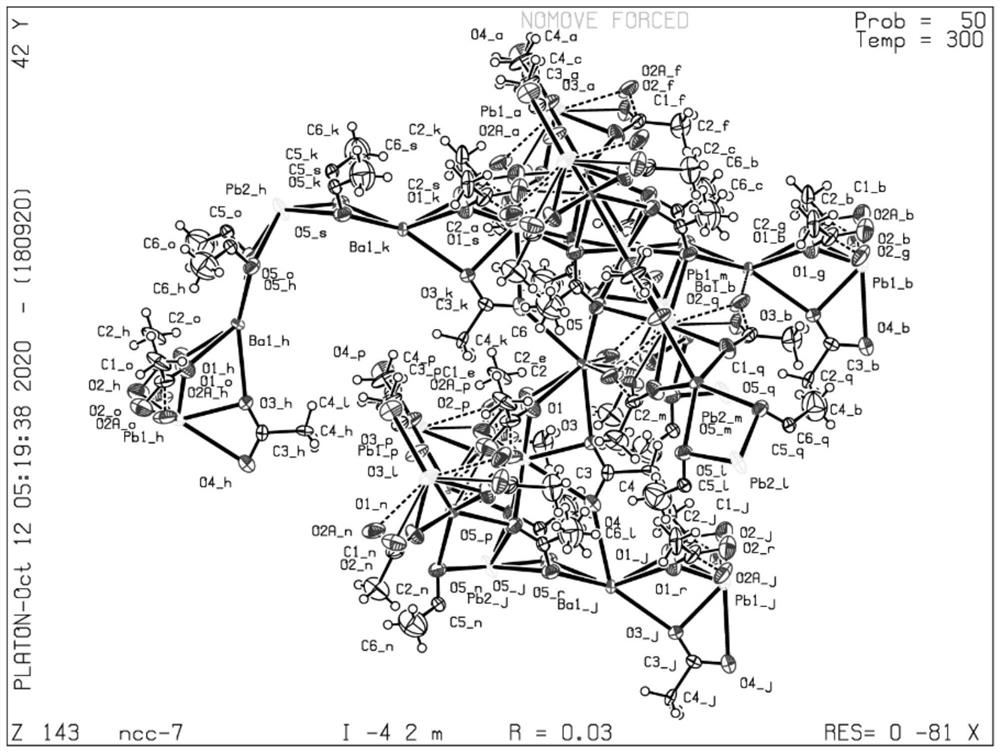

[0047] This embodiment provides a kind of Pb, Ba bimetallic MOFs, the molecular formula of Pb, Ba bimetallic MOFs is: Ba 4 Pb 4 (CH 3 CO 2 ) 8 [(CH 6 CO 2 ) 4 Pb](CH 3 CO 2 ) 4 , and its crystal structure parameters are shown in Table 1.

[0048] Table 1 Crystal structure parameters of PbBa-MOFs

[0049]

[0050]

[0051]

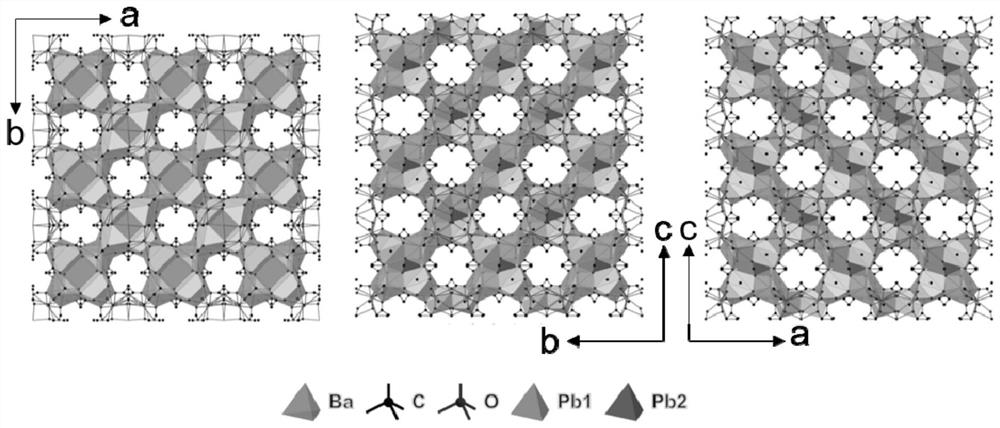

[0052] The structure of Pb, Ba bimetallic MOFs is as follows Figure 1 to Figure 5(c) shown. to Ba 4 Pb 4 (CH 3 CO 2 ) 8 [(CH 6 CO 2 ) 4 Pb](CH 3 CO 2 ) 4 The structure description:

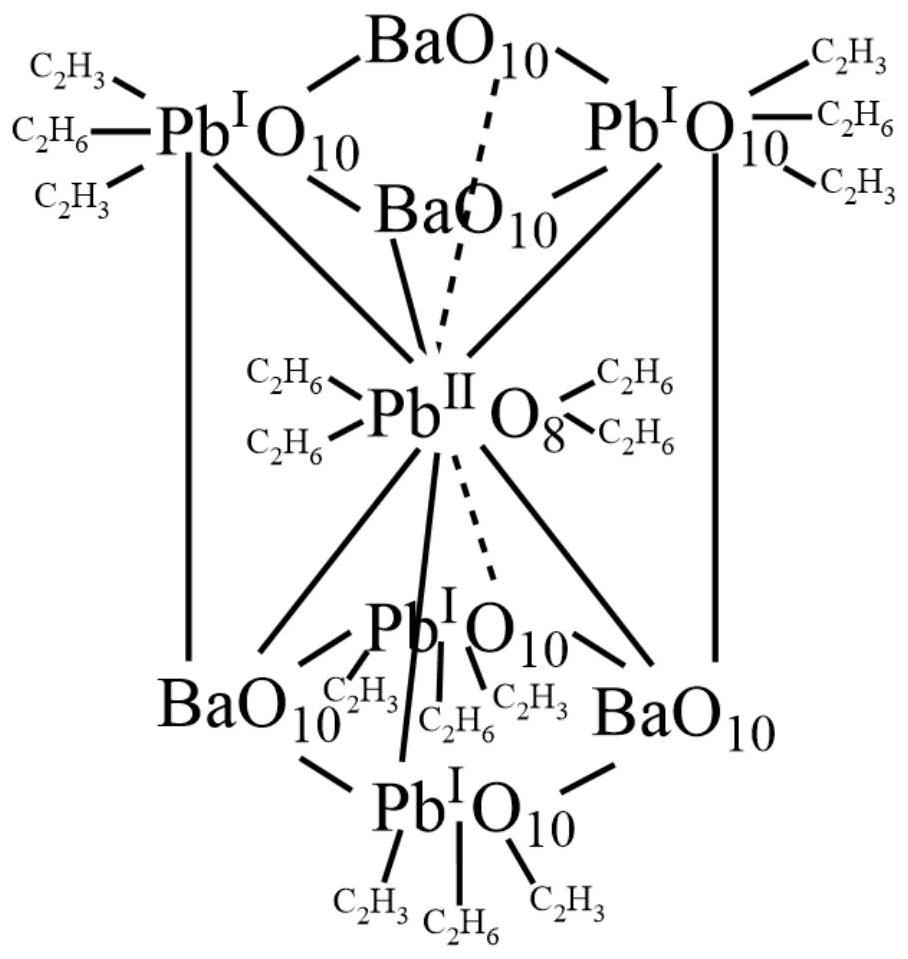

[0053] In the structure, the smallest repeating unit (Secondary Building Unit (SBU)) consists of nine polyhedrons, such as Figure 4 as shown in a. SBUs involve three main building units (PBUs), including 4 Pb Ⅰ o 10 (Irregular tetradecahedron), 1 Pb Ⅱ o 8 (Irregular hexahedron) and 4 BaO 10 (Irregular Tridecahedron). SBUs contain two Pb Ⅰ o 10 and two BaO 10 The 4 PBUs of the unit are in Figure 4 A rectangular plane (named after A1) ...

Embodiment 2

[0069] This example presents the application of the Pb, Ba bimetallic MOFs of Example 1 as a combustion catalyst for a solid double-base propellant. Specific as Figures 14 to 23 shown.

[0070] During the pyrolysis process of PbBa-MOFs, the main gaseous decomposition product of PbBa-MOFs is H 2 O(m / z=18), CO(m / z=28), CO 2 (m / z=44) and some small molecular fragments -CH 3 (m / z=15), also observed O (m / z=16), -OH (m / z=17), -C 2 h 3 (m / z=27), -C 2 h 6 (m / z=30).

[0071] The FTIR curve of the pyrolysis process of PbBa-MOFs is as follows Figure 15 Shown, describing the same product as the mass spectrum, 2360, 1383 and 669 cm -1 The peak at is attributed to CO 2 The presence of, 1750 and 656cm -1 The peak at is attributed to H 2 The appearance of O. 1230cm -1 The infrared absorption at can be attributed to the vibration of the C–H bond.

[0072] Such as Figure 16 As shown, there are two peaks in the pyrolysis process of pure CL-20. The weak endothermic peak at 168...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com