1,8-dyhydroxy-4,5-dinitroanthraquinone copper compound and preparation method and application of copper compound

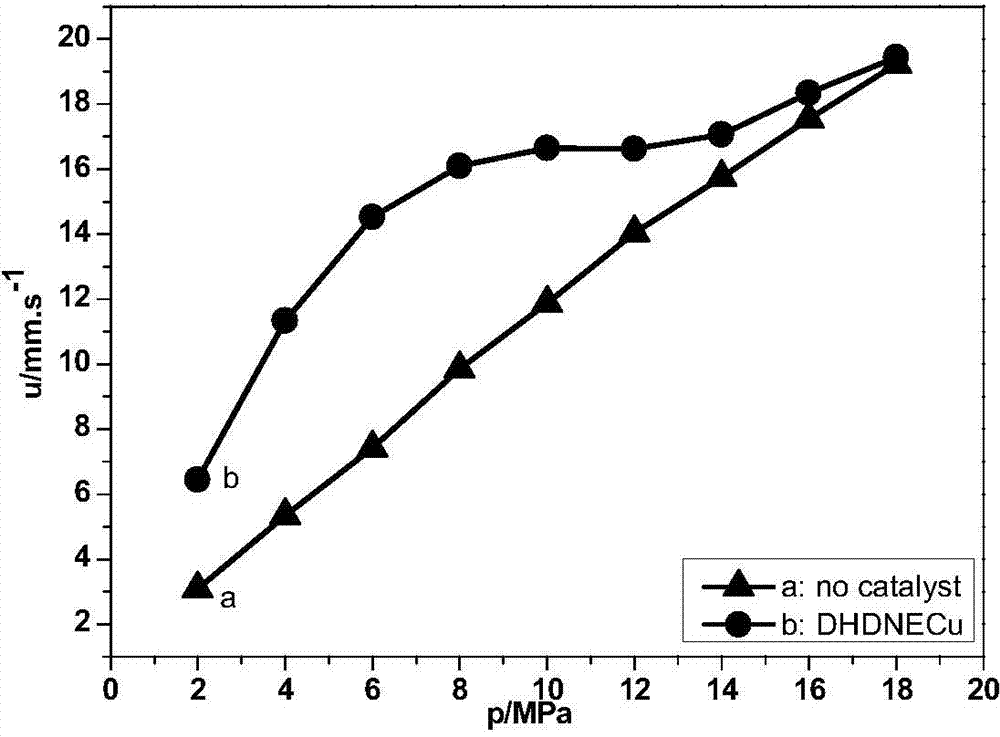

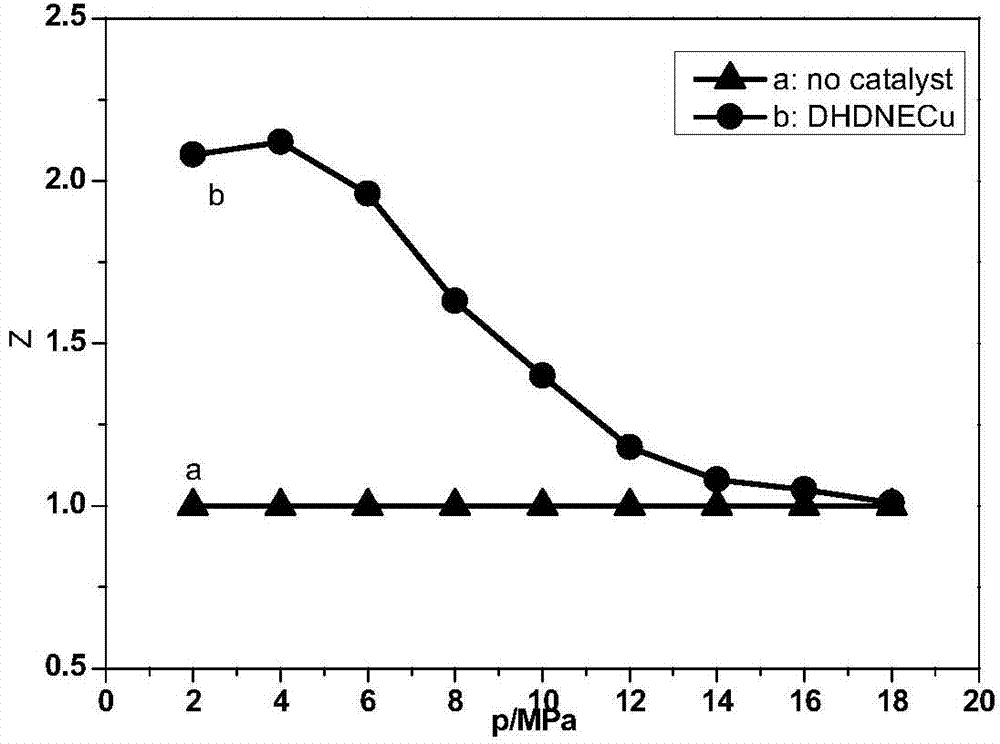

A technology of copper dinitroanthraquinone and dinitroanthraquinone is applied in the field of combustion catalysts for solid propellants, and can solve the problems of reduced energy level of solid propellants, unfavorable missile guidance and stealth, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

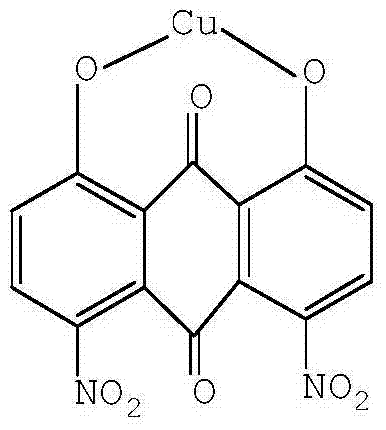

[0022] Synthesis of Copper 1,8-Dihydroxy-4,5-Dinitroanthraquinone

[0023] Weigh 3.31g (0.01mol) of 1,8-dihydroxy-4,5-dinitroanthraquinone, disperse it in 30mL of deionized water, fully dissolve it into a clear solution with 0.84g (0.021mol) of sodium hydroxide, adjust The pH value of the solution is 9; weigh 2.42g (0.01mol) copper nitrate, dissolve it in 50mL deionized water to form a solution, add it to the 1,8-dihydroxy-4,5-dinitroanthraquinone solution, stir and mix Uniform; at a constant temperature of 70°C, stir for 3 hours, then cool and stand still, wash the precipitate with deionized water several times, filter and dry to obtain brown 1,8-dihydroxy-4,5-dinitroanthraquinone Copper compound 3.7g, yield 94.5%.

[0024] Characterization of copper 1,8-dihydroxy-4,5-dinitroanthraquinone

[0025] Infrared analysis

[0026] In the infrared spectrum of the raw material 1,8-dihydroxy-4,5-dinitroanthraquinone, the peak of C=O appears at 1732cm -1 , the -OH peak on the anthra...

Embodiment 2

[0032] Weigh 3.31g (0.01mol) of 1,8-dihydroxy-4,5-dinitroanthraquinone, disperse it in 30mL of deionized water, fully dissolve it into a clear solution with 0.84g (0.021mol) of sodium hydroxide, adjust The pH value of the solution is 9; weigh 2.42g (0.01mol) copper nitrate, dissolve it in 50mL deionized water to form a solution, add it to the 1,8-dihydroxy-4,5-dinitroanthraquinone solution, stir and mix Uniform; keep the temperature at 75°C, stir and react for 3 hours, then cool and stand still, wash the precipitate with deionized water several times, filter and dry to obtain brown 1,8-dihydroxy-4,5-dinitroanthraquinone Copper compound 3.65g, yield 93.35%.

Embodiment 3

[0034] Weigh 3.31g (0.01mol) of 1,8-dihydroxy-4,5-dinitroanthraquinone, disperse it in 30mL of deionized water, fully dissolve it into a clear solution with 0.84g (0.021mol) of sodium hydroxide, adjust The pH value of the solution is 9; weigh 3.3g (0.01mol) copper nitrate, dissolve it in 50mL deionized water to form a solution, add it to the 1,8-dihydroxy-4,5-dinitroanthraquinone solution, stir and mix Uniform; keep the temperature at 60°C, stir and react for 4 hours, then cool and stand still, wash the precipitate with deionized water several times, filter and dry to obtain brown 1,8-dihydroxy-4,5-dinitroanthraquinone Copper compound 3.58g, yield 91.56%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com