Preparation method of super-thermite Al/PbO nano-composite energetic material

A super thermite and nano-composite technology, applied in the direction of offensive equipment, compressed gas generation, etc., can solve the problems of poor product dispersion uniformity, high cost, and long preparation cycle, and achieve excellent catalytic effect and low production cost , The effect of short preparation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] Concrete preparation method comprises the following steps:

[0025] (1) select organic or inorganic lead salt, organic or inorganic base as raw material; described lead salt is preferably lead acetate; described base is preferably sodium hydroxide or potassium hydroxide.

[0026] (2) Dissolve the pretreated organic lead salt (dried to remove water) and inorganic base in ethylene glycol solution under ultrasonic conditions with magnetic (mechanical) stirring, and after they are completely dissolved, the two are miscible, and milky white is formed immediately Pb(OH) 2 Glue, after a while add nano-aluminum powder.

[0027] The pretreated lead salt has a concentration of 0.08-0.8 mol / L, and 0.08-1.2 mol of alkali is added to each liter of lead salt solution, wherein the alkali concentration is 0.08-0.8 mol / L.

[0028] (3) Use a magnetic stirrer to stir for several hours (2-6h) under constant temperature water bath conditions. After the reaction solution is separated, wash...

Embodiment 1

[0032] Accurately weigh 1.3g (4mmol) of pretreated lead acetate and 0.352g (8.8mmol) of sodium hydroxide, ultrasonically dissolve them in 10ml and 22ml of ethylene glycol respectively at room temperature, and mix the two after they are completely dissolved After 4-6 minutes, add 0.1008g (3.7mmol) of nano-aluminum powder (about 50nm), and stir with a magnetic stirrer (Mot=3) in a constant temperature water bath (80°C) for 2.5h. After the reaction solution was separated, the precipitate was washed several times with deionized water and absolute ethanol, and treated in a vacuum oven for 28 hours to obtain a black powder Al / PbO super thermite.

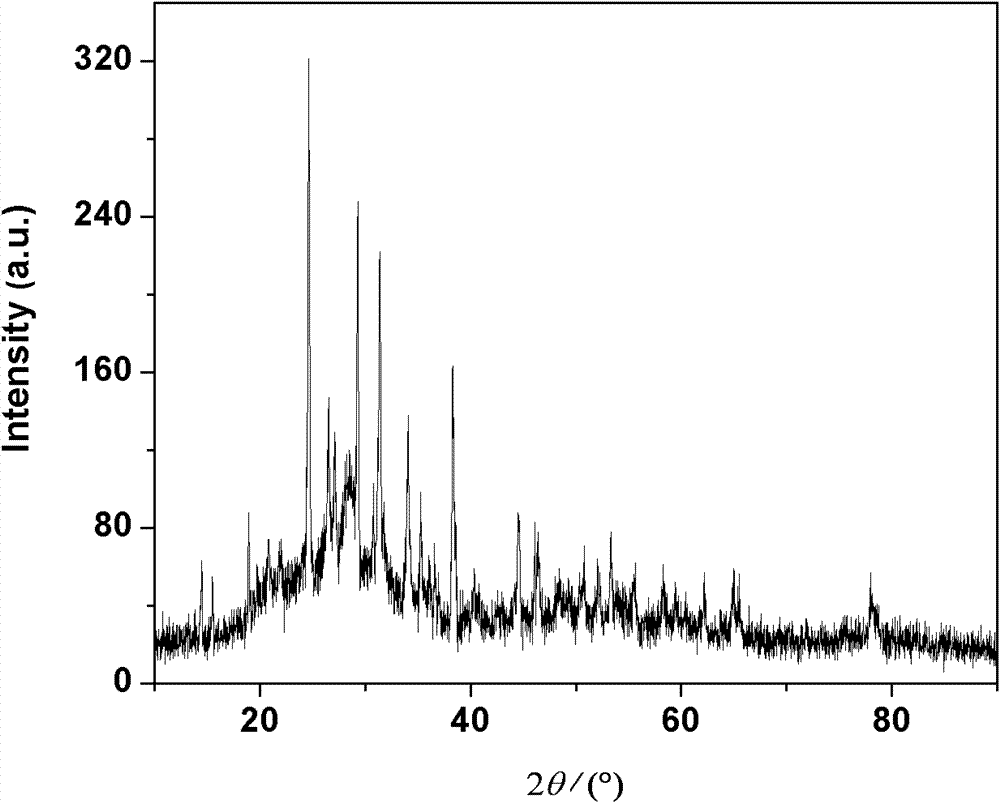

[0033] The structure and properties of the product were characterized by field emission scanning electron microscope (SEM), X-ray powder diffraction (XRD), infrared spectroscopy (IR), X-ray fluorescence spectroscopy (XRF) and thermogravimetric analyzer (TG).

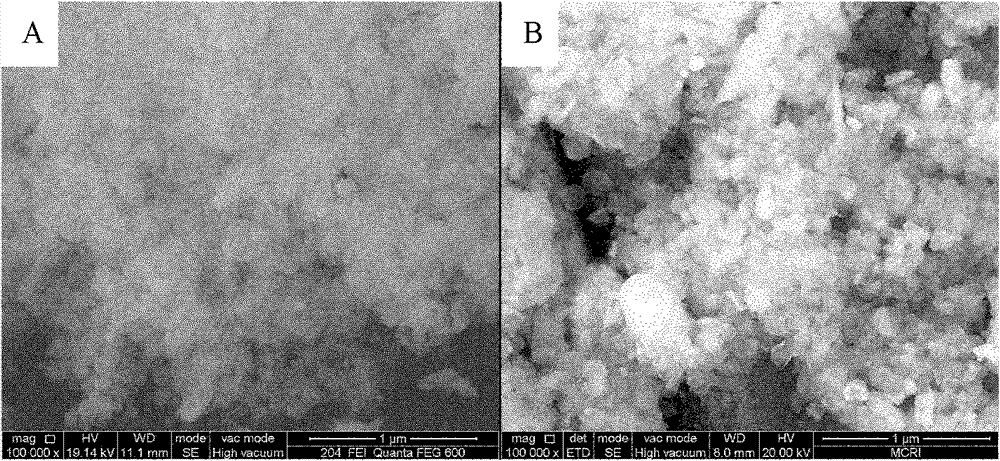

[0034] Such as figure 1 As shown in A, the product is uniformly distributed sph...

Embodiment 2

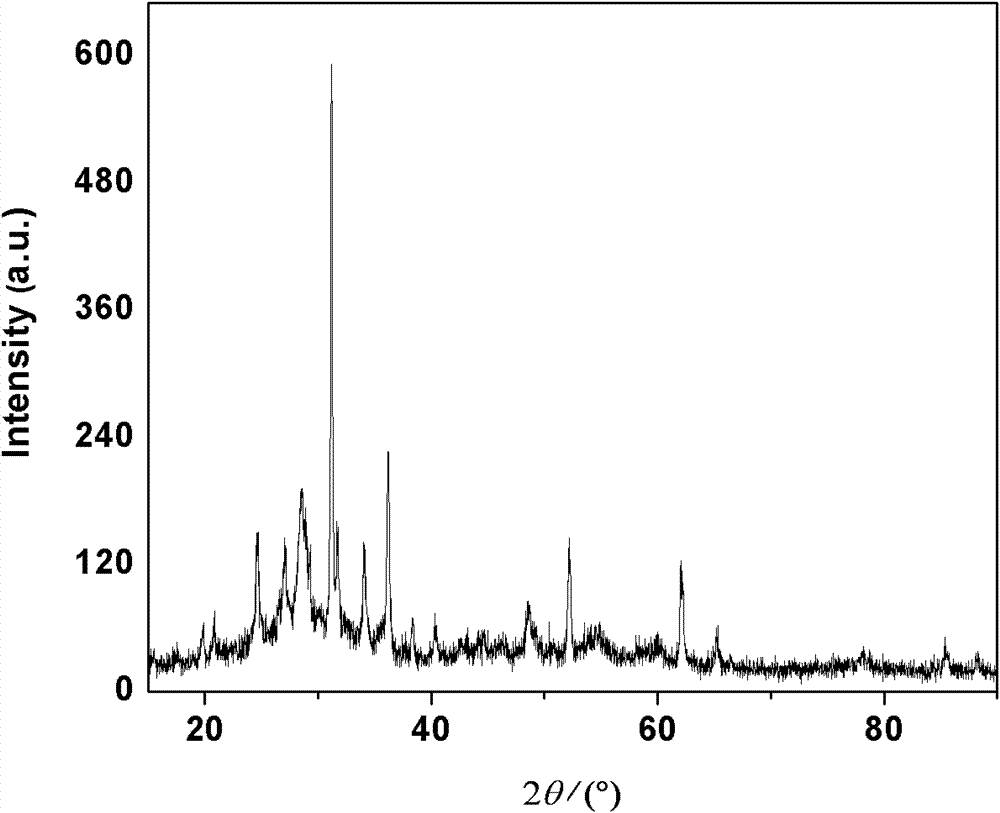

[0037] Accurately weigh 1.3g (4mmol) of pretreated lead acetate trihydrate and 0.493g (8.8mmol) of potassium hydroxide, and ultrasonically dissolve them in 10ml and 22ml of ethylene glycol respectively at room temperature. It is miscible, and a milky white sol is obtained immediately. After 4-6 minutes, 0.1008g (3.7mmol) of nano-aluminum powder (about 50nm) is added, and stirred with a magnetic stirrer (Mot=3) in a constant temperature water bath (75°C) for 2.0h. After the reaction solution was separated, the precipitate was washed several times with deionized water and absolute ethanol, and treated in a vacuum oven for 24 hours to obtain a black powder Al / PbO super thermite.

[0038] The structure and properties of the product were characterized by field emission scanning electron microscope (SEM), X-ray powder diffraction (XRD), infrared spectroscopy (IR), X-ray fluorescence spectroscopy (XRF) and thermogravimetric analyzer (TG).

[0039] Such as figure 1 As shown in B, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com