Multiple catalyst system for olefin polymerization and polymers produced therefrom

A technology of polymers and olefins, applied in the field of producing polyolefin adhesives

Active Publication Date: 2005-12-07

EXXONMOBIL CHEM PAT INC

View PDF296 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Reactor blends, also known as intimate blends (including compositions of two or more polymers produced in the same reactor or series of reactors), are often used to address this issue, however to find Catalyst systems operating under the same conditions to produce different polymers is a challenge

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1-4

[1212] Table 1

Embodiment 5-8

[1214] Use racemic-dimethylsilyl bis(2-methyl-4-phenylindenyl) dimethyl zirconium and dimethylsilyl (tetramethylcyclopentadienyl) (tert-butyl) (Amino) dimethyl titanium prepared 4 samples at a temperature of 100°C in the catalyst ratio range. The polymerization reaction was carried out in accordance with the general procedure described above.

[1215] Table 2

Embodiment 9-15

[1217] table 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Global softening point | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Login to View More

Abstract

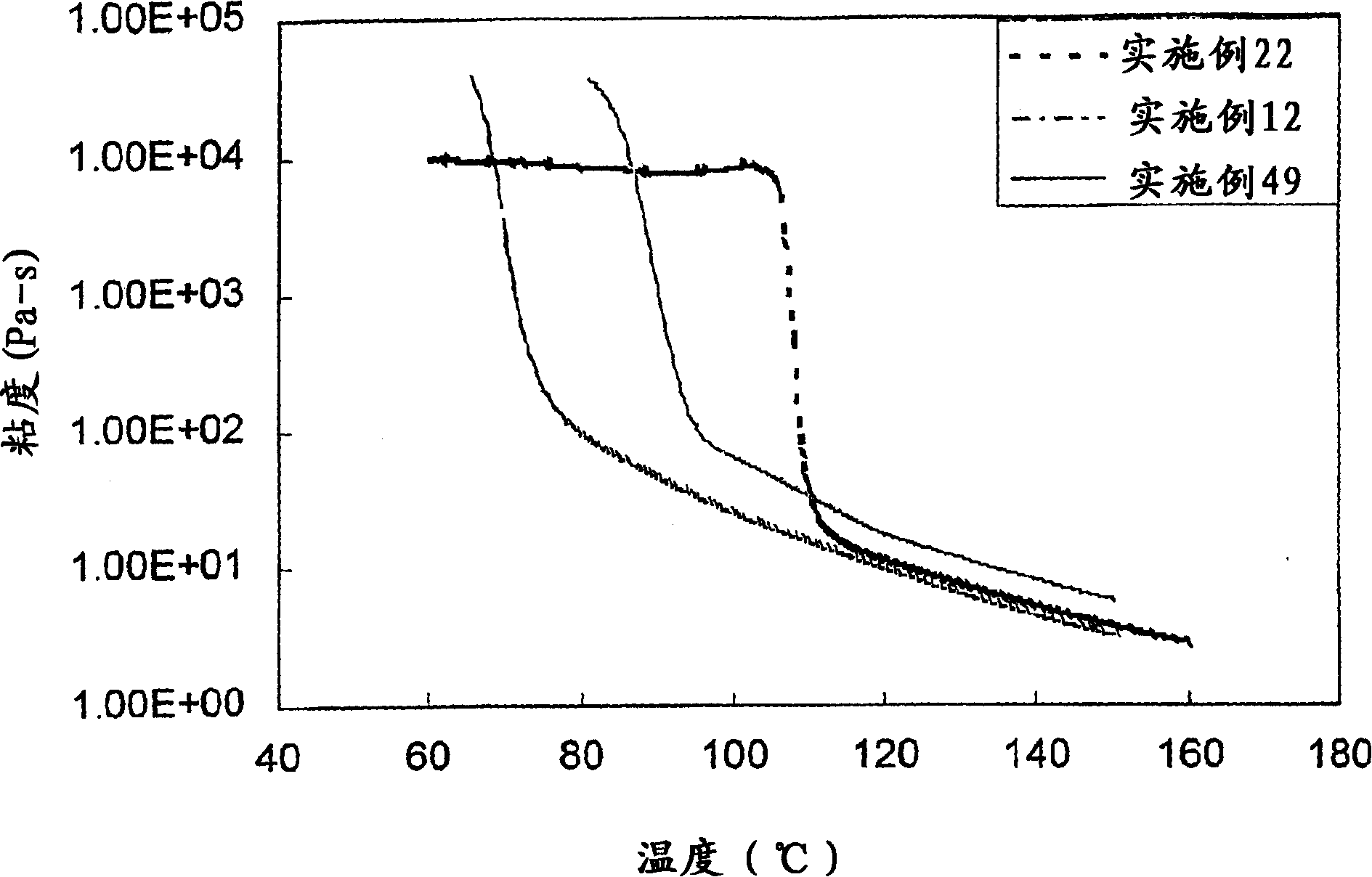

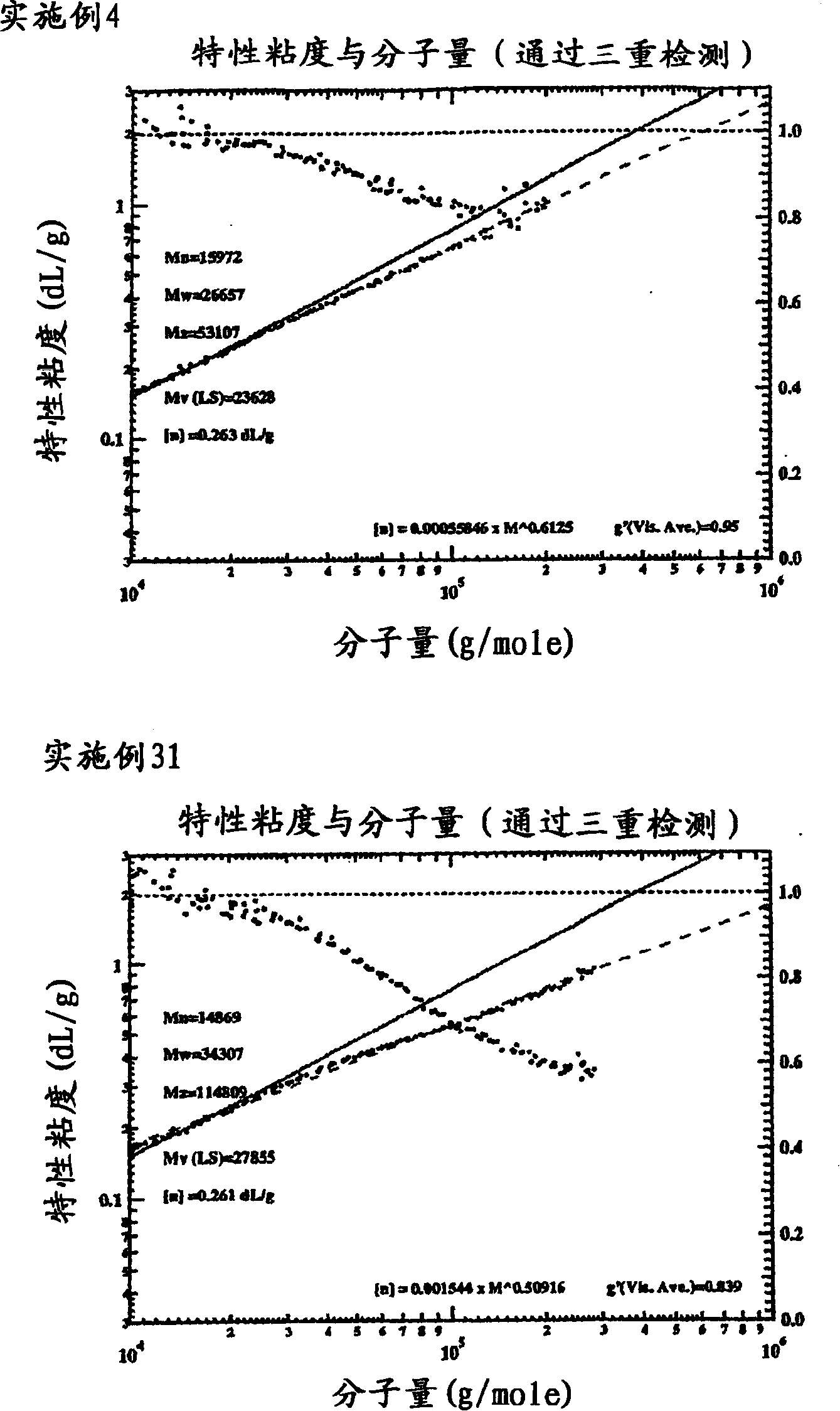

This invention relates to a polymer comprising one or more C3 to C40 olefins, optionally one or more diolefins, and less than 15 mole % of ehtylene, where the polymer has: a) a Dot T-Peel of 1 Newton or more; and b) a branching index (g') of 0.95 or less measured at the Mz of the polymer; c) an Mw of 100,000 or less and to a continuous process to produce a branched olefin polymer comprising 1) selecting a first catalyst component capable of producing a polymer having an Mw of 100,000 or less and a crystallinity of 5% or less under selected polymerization conditions; 2) selecting a second catalyst component capable of producing polymer having an Mw of 100,000 or less and a crystallinity of 20% or more at the selected polymerization conditions; 3) contacting the catalyst components in the presence of one or more activators with one or more C3 to C40 olefins, and, optionally one or more diolefins; 4) at a temperature of greater than 100 DEG C; 5) at a residence time of 120 minutes or less; 6) wherein the ratio of the first catalyst to the second catalyst is from 1:1 to 50:1; 7) wherein the activity of the catalyst components is at least 100 kilograms of polymer per gram of the catalyst components; and wherein at least 20% of the olefins are converted to polymer.

Description

[0001] Related case information [0002] This application claims priority to provisional application USSN 60 / 418,482 filed on October 15, 2002 under the title of "Multi-catalyst system for olefin polymerization and polymers produced therefrom". This application also claims the priority of USSN 60 / 460,714 filed on April 4, 2003 under the title of "Polyolefin Binder Composition and Products Prepared from It". [0003] This application is related to USSN 60 / 199,093 filed on April 21, 2000 and US2000000199093P filed on April 20, 2001 (requiring USSN 60 / 199,093 as priority). This application is also related to USSN 60 / 171,715 filed on December 21, 1999, USSN 09 / 745,394 mentioned on December 21, 2000, and USSN 09 / 746,332 mentioned on December 21, 2000. This application is also related to WO 01 / 81493. Technical field [0004] The present invention relates to a method for polymerizing olefins with multiple catalysts and polymers produced therefrom. The present invention particularly relate...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08F210/06

Inventor 江培军A·德克梅日安J·A·M·卡尼克C·L·西姆斯R·阿伯哈里C·A·加西亚-佛朗哥D·R·约翰斯拉德

Owner EXXONMOBIL CHEM PAT INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com