Elastic mattress for bed and producing method thereof

An elastic pad and structure technology, applied in mattresses, spring mattresses, applications, etc., can solve the problems of easy dislocation, difficulty in use, and uneven height, and achieve lightweight, eliminate dislocation and unevenness, and increase strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 2

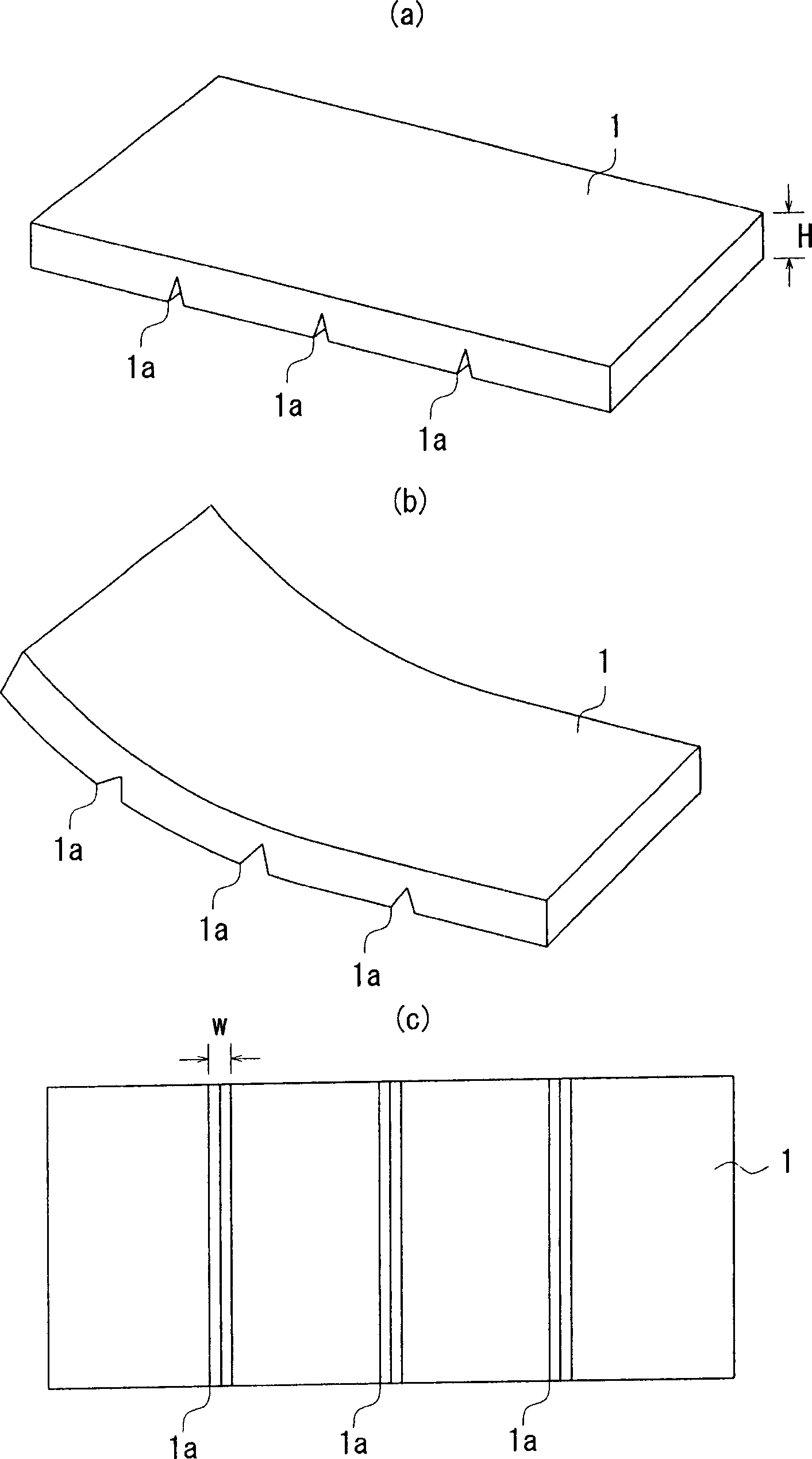

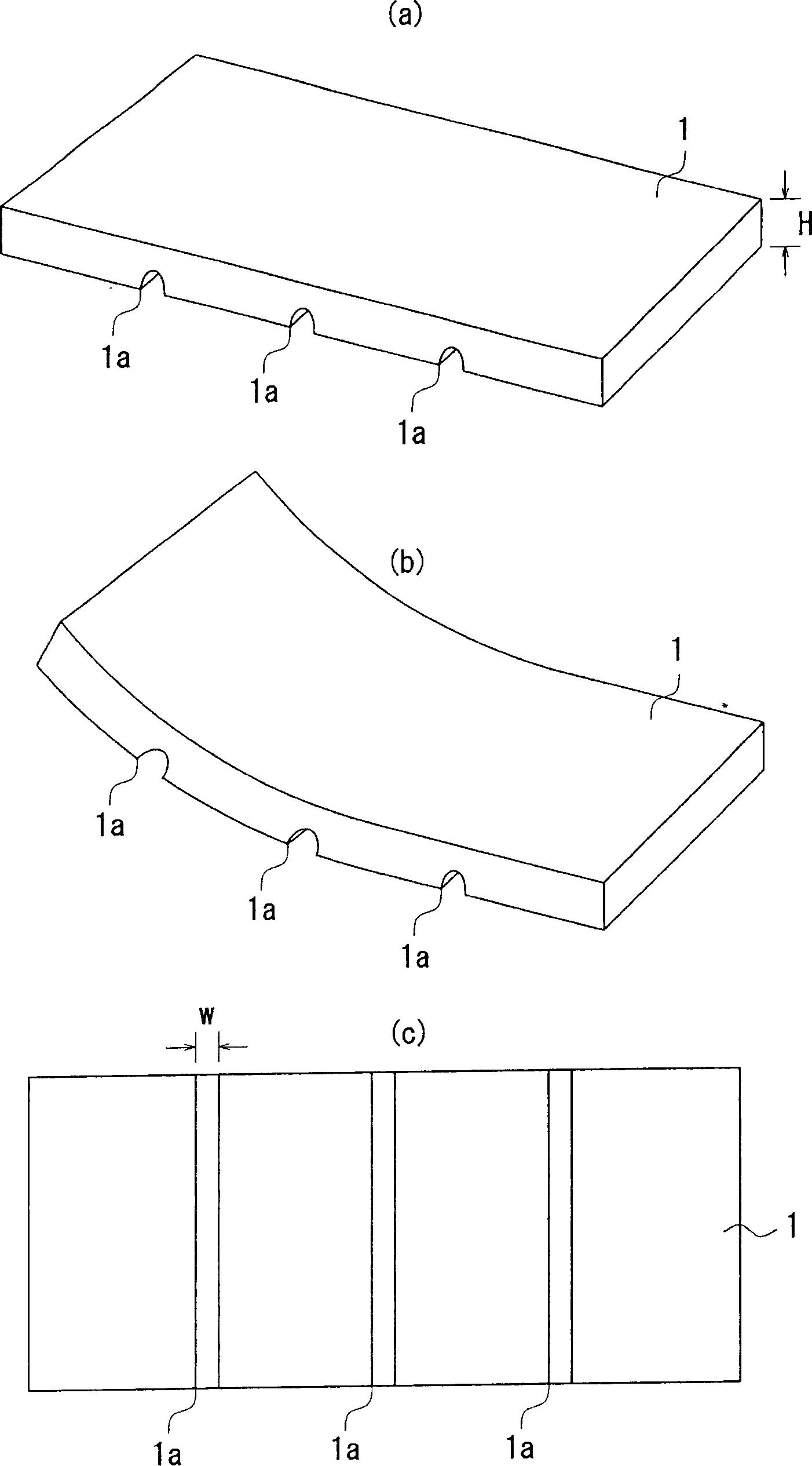

[0082] Embodiment 2 has the same effect as Embodiment 1. In addition, due to the physical properties of the three-dimensional network structure 5 of Embodiment 1, the elastic pad 2 for a variable-angle bed can be partially bent by bending upward, and a compressive stress is applied to the bent lower surface, which may cause wrinkles. Deformation phenomena such as pleats, but Embodiment 2 can resolve this phenomenon.

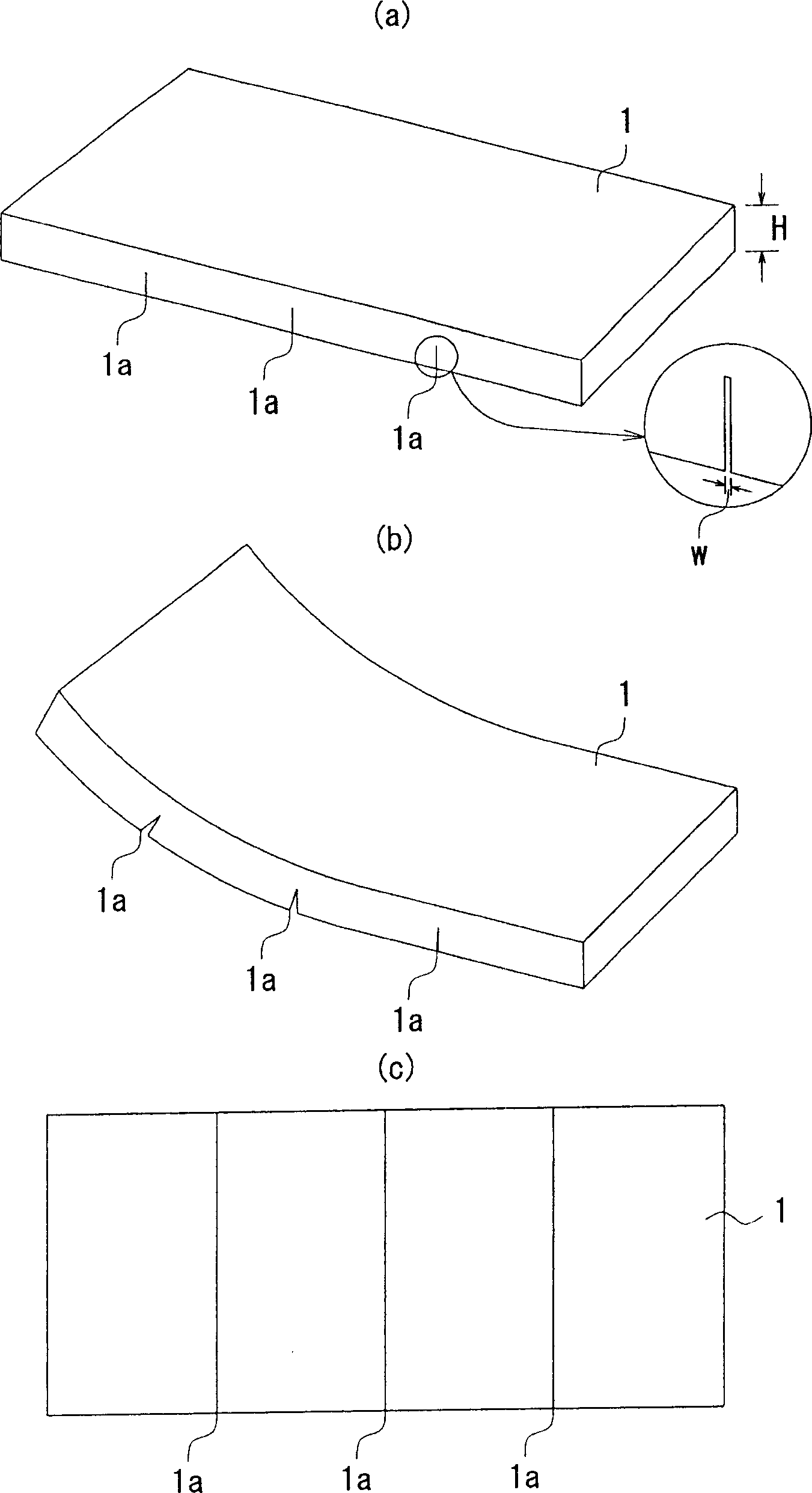

[0083] Below, use image 3 Embodiment 3 will be described. The elastic pad 3 for the partially bendable variable-angle bed of Embodiment 3, such as image 3 As shown in (a), it is substantially the same as Embodiment 2 except that the continuous groove 3 a is arc-shaped when viewed from the side. That is, it is an elastic pad in which the triangular facets of the continuous groove 2a in the second embodiment are curved. image 3 (b) shows the state when the partially bendable elastic pad 3 for a variable-angle bed made of the three-dimensional network structu...

Embodiment approach 4

[0086] Embodiment 4 has the same effect as Embodiment 1. On the underside of the elastic pad 4 that can be partially bent and used for variable-angle beds, the aforementioned continuous groove 4a forms a grid-like structure, such as Figure 5 (a), Figure 5 As shown in (b), the elastic pad for a partially bendable variable-angle bed can be bent upward from any of the quadrangular sides. Accordingly, for example, a cushion 6 is placed under the elastic pad 4, and the head 7 of the person lying on the elastic pad 4 can be lifted up to the back 8 to bend the elastic pad (refer to Figure 5 (a)), the side of the health lying on the elastic pad 4 can also be lifted upwards to bend the elastic pad (refer to Figure 5 (b)). By applying the elastic pad 4 to the conventional fixed bed, it not only has the same effect as the partly bendable variable-angle bed, that is, the leg-loading part can be raised, or the backrest part can be raised, and it can also be lifted from the supine sta...

Embodiment

[0127] The size of the bed of the three-dimensional network structure is 1910mm in length, 840mm in width, and 75mm in thickness. Figure 17 The weight of the spring rigid soft type is 10.5kg, the porosity is 91%, and the outer diameter of the filament is 2-3mm; Figure 18 The weight of the spring-rigid rigid type is 14.5kg, the porosity is 88%, and the outer diameter of the filament is 2-3mm. Partially bendable vari-angle gutters are a common bed configuration that has not yet been formed. We measured the distribution of body pressure of a test subject with a body weight of 60 kg while lying on the bed elastic mattress. The shades shown in the divided upper, middle and lower areas of the screen represent the shoulder blades, buttocks, and heels, respectively. The result is as Figure 17 and Figure 18 As shown, it was found that the body pressure has been dispersed to below 32mmHg, which is the limit of bedsore occurrence.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com