System and method for checking wiring across crack on main machine board

An inspection method and inspection system technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of high labor cost, inaccurate inspection, and inability to completely solve the EMI problem of the motherboard, so as to avoid EMI problems, effects of increasing plausibility and completeness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

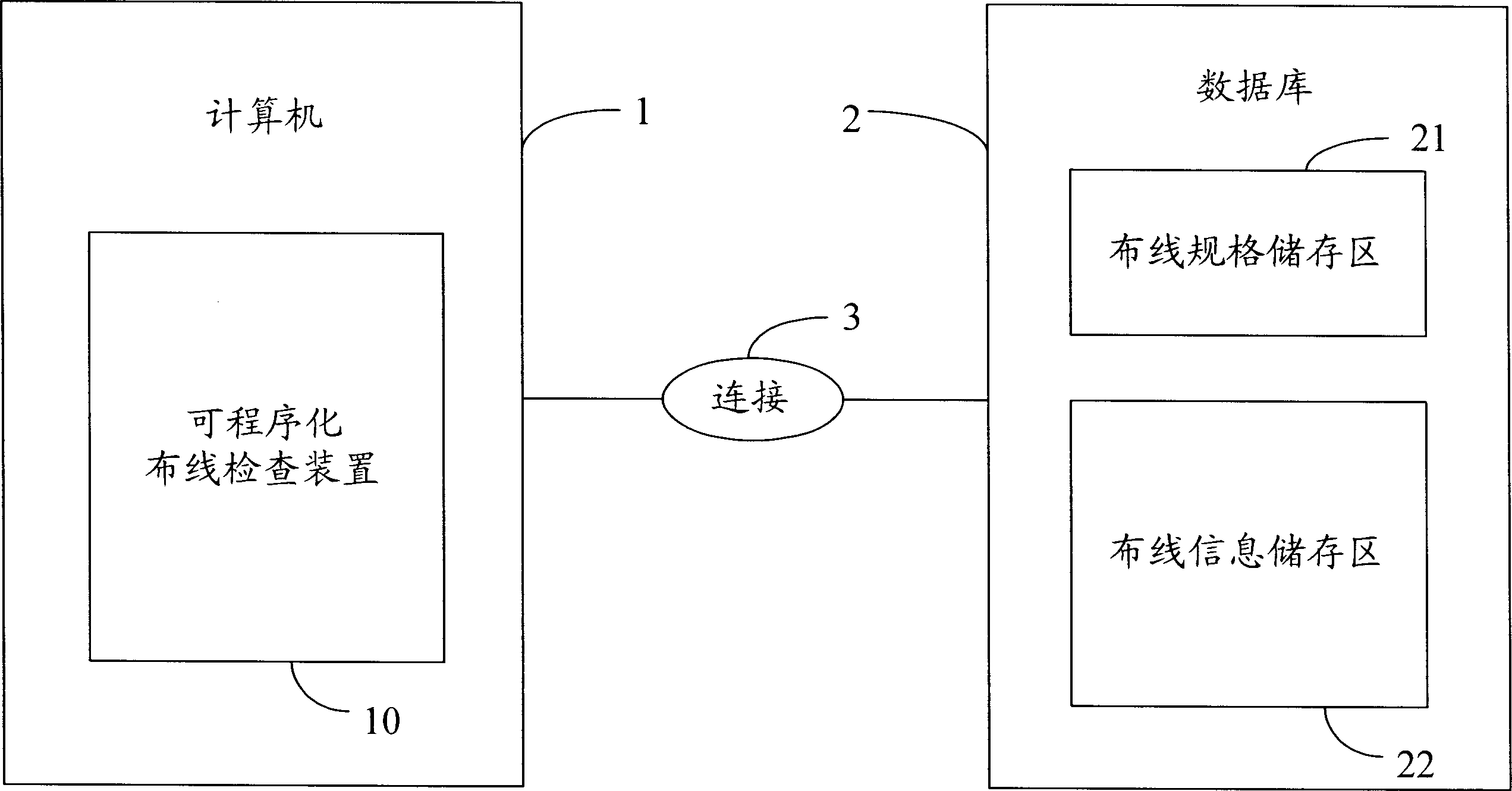

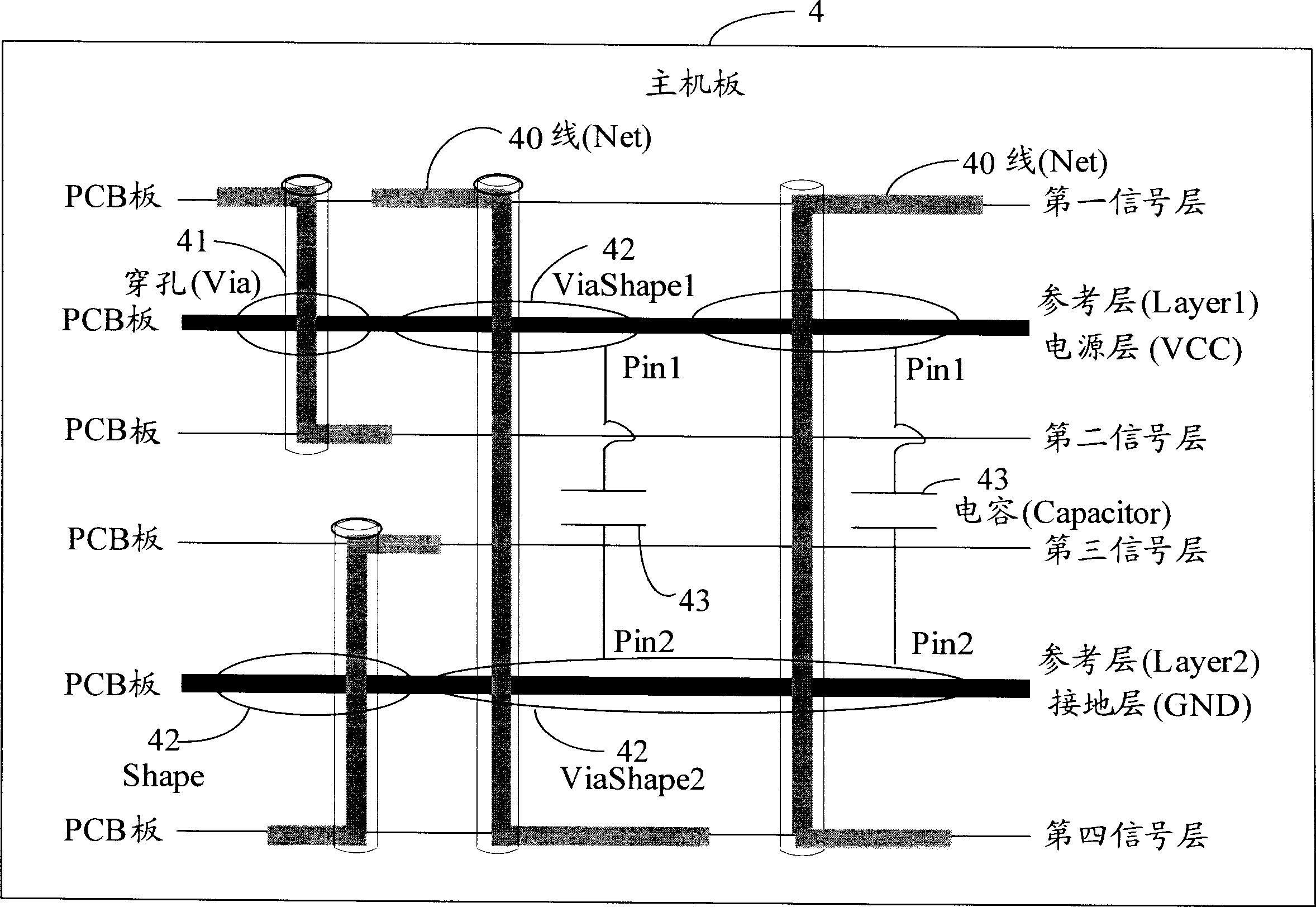

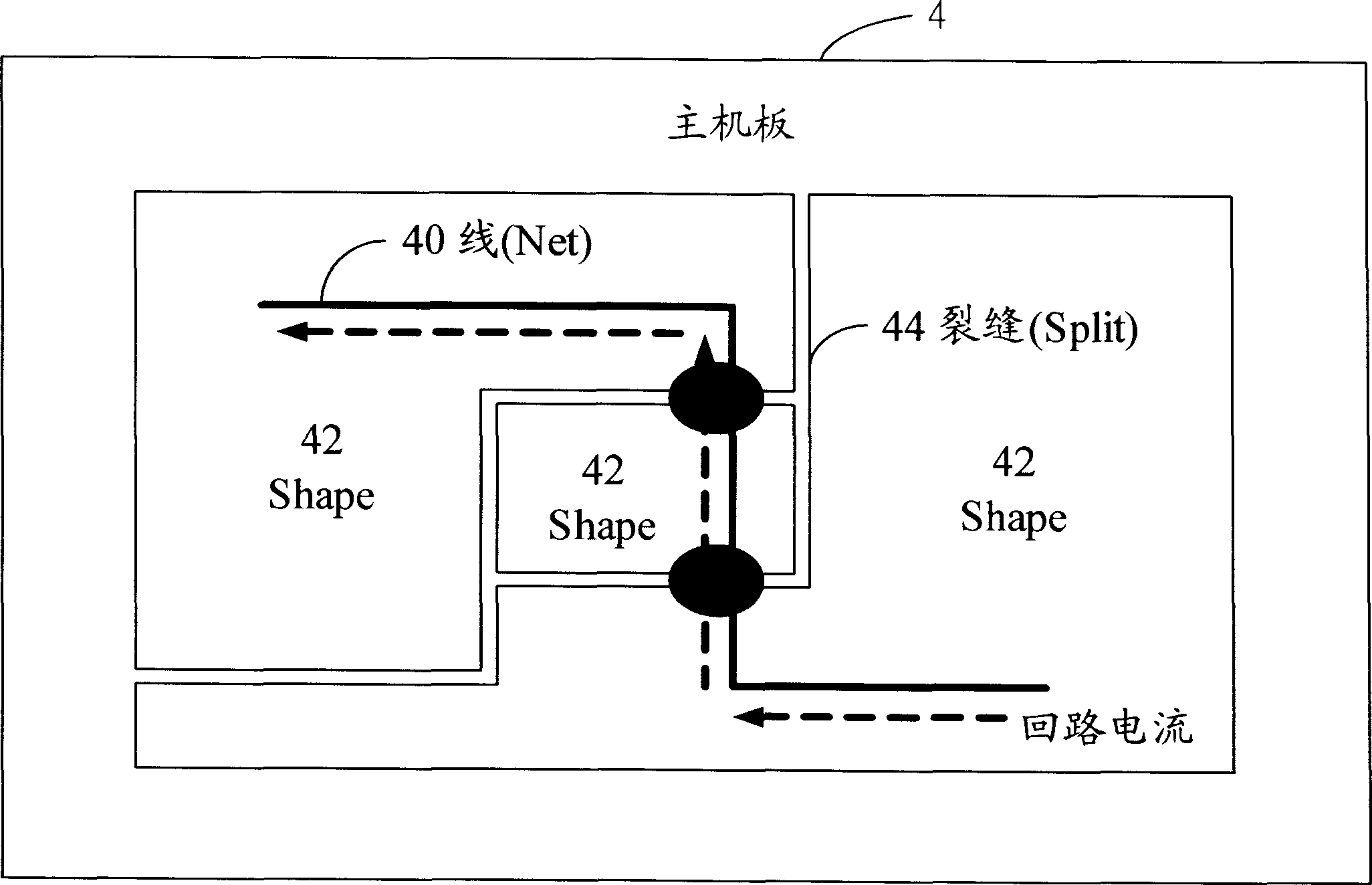

[0020] figure 1Shown is the hardware architecture diagram of the wiring inspection system across the crack on the motherboard of the present invention. The wiring inspection system spanning cracks on the motherboard includes a computer 1 , a database 2 and a connection 3 , and the computer 1 is connected to the database 2 through the connection 3 . The computer 1 mainly includes a programmable wiring checking device 10, which is used to check the rationality of the wiring of the motherboard without changing the reference layer and the wiring of the changing reference layer. The database 2 is logically divided into a wiring specification storage area 21 and a wiring information storage area 22 . Among them, the wiring specification storage area 21 is used to store the standard specification information for pre-determining motherboard wiring, including wiring specification information, capacitance information and wiring perforation information; the wiring information storage ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com