Vehicle drive unit

A traveling mechanism and vehicle technology, applied in vehicle springs, vehicle components, elastic suspensions, etc., can solve the problems of high transmission torque and increase in the axial diameter of the transmission device, and achieve large adjustment torque, reduced structure height, and production cost. economic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

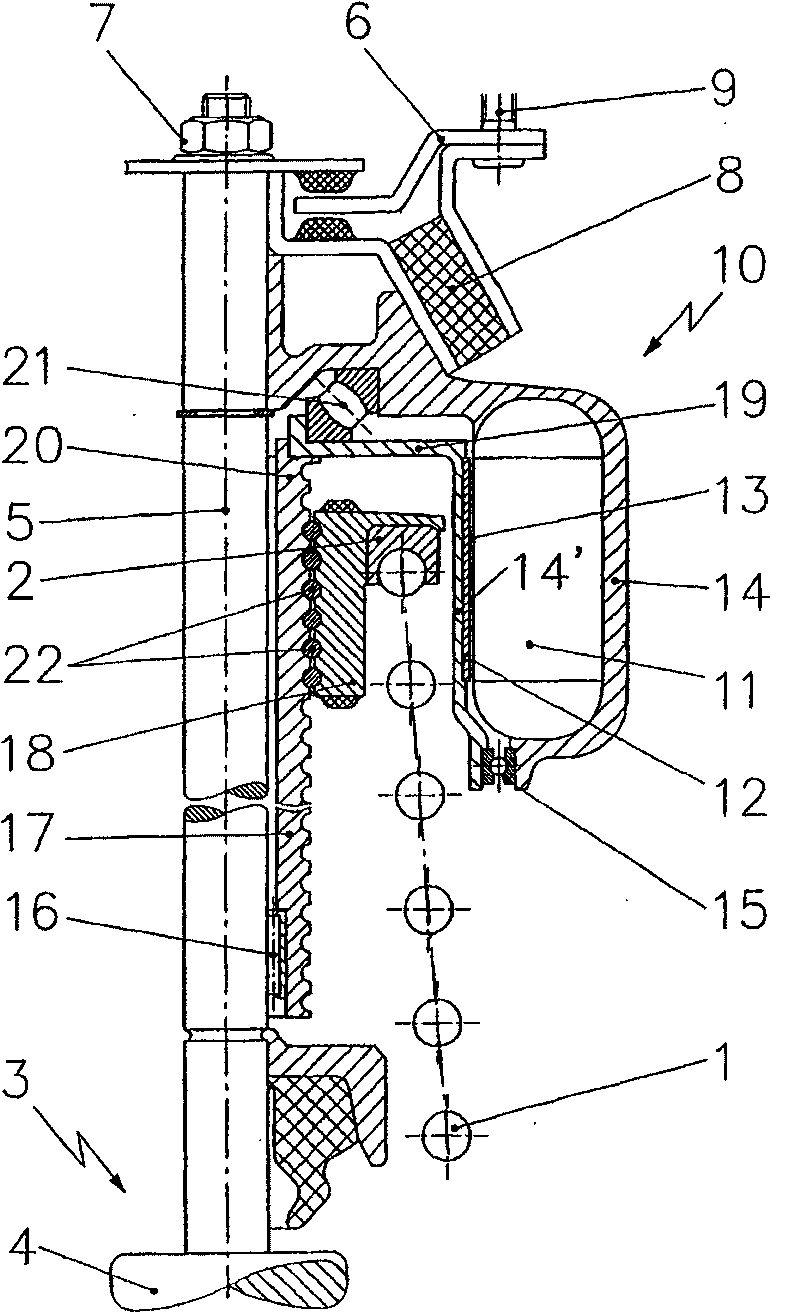

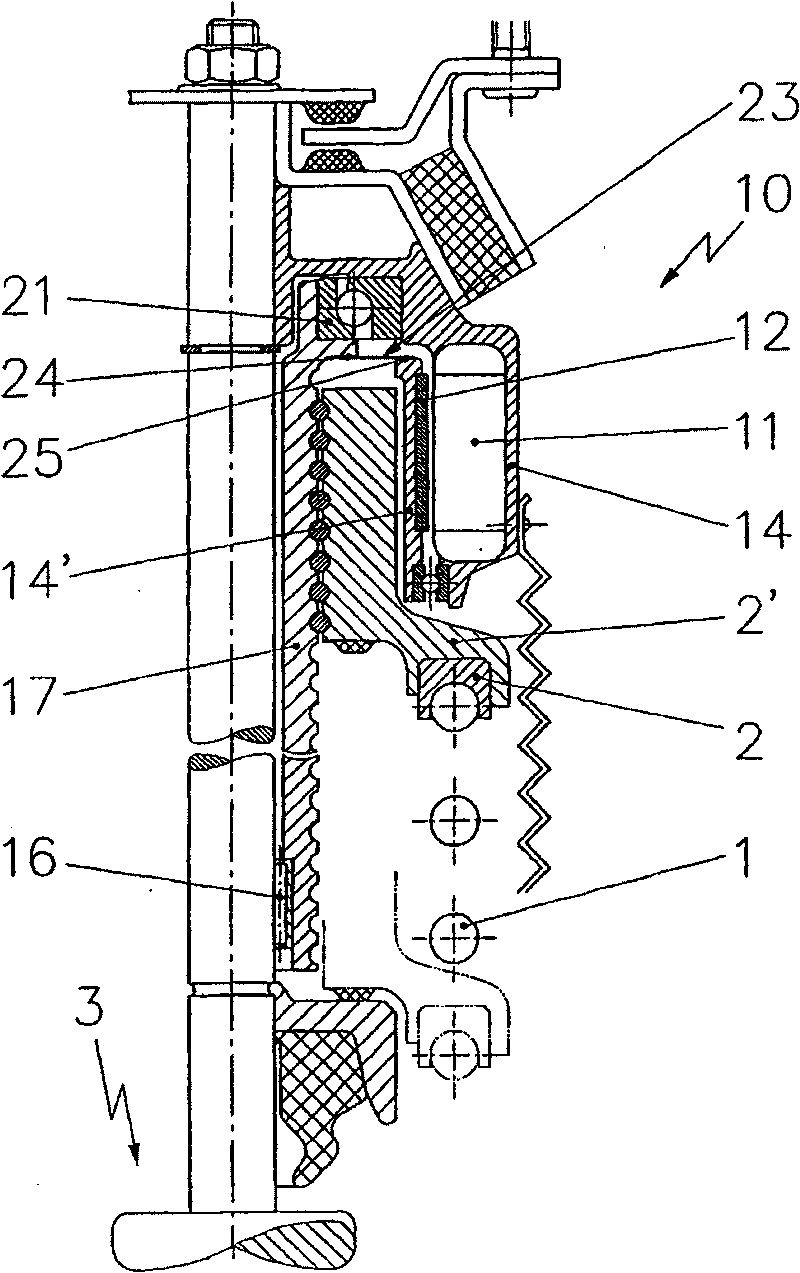

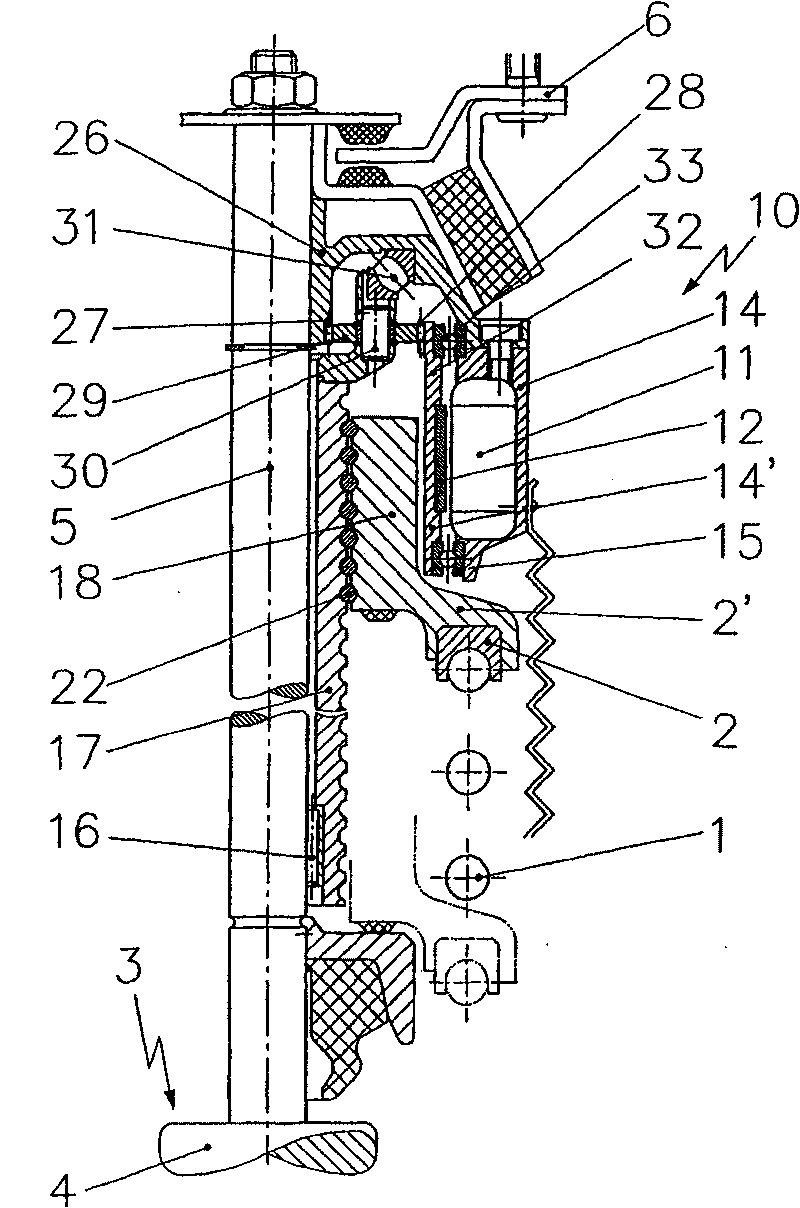

[0011] figure 1 The shown spring frame is used to support the coil spring 1, wherein in this embodiment, as shown in the figure, one end of the coil spring 1 is supported on the spring seat 2. At the inner center of the coil spring 1, there is a A damper 3 of a piston rod 5 which is inserted axially pivotably into the damper sleeve 4. This damper can form a structurally predetermined damping. Of course, dampers with variable damping forces can also be used. The connection of the wheel suspension is realized via a flange not further shown in the bottom area. The connection of the piston rod 5 is realized in a known manner via a component 6 of the body structure. For this purpose, the piston rod 5 is connected by means of a nut 7 is screwed onto an angle-elastic (winkelastish) and shock-elastic connecting piece 8. This is in turn operatively connected to the body structure component 6 by means of bolts 9. The spring carrier works together with an adjustment device 10, which is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com