Helical groove water lubricating rubber alloy bearing

A rubber alloy and water-lubricated technology, which is applied in the direction of sliding contact bearings, rotating bearings, bearings, etc., can solve the problems of small load capacity, short service life, weak ability to discharge sediment and impurities, etc., and achieve reduction Friction and wear, low cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

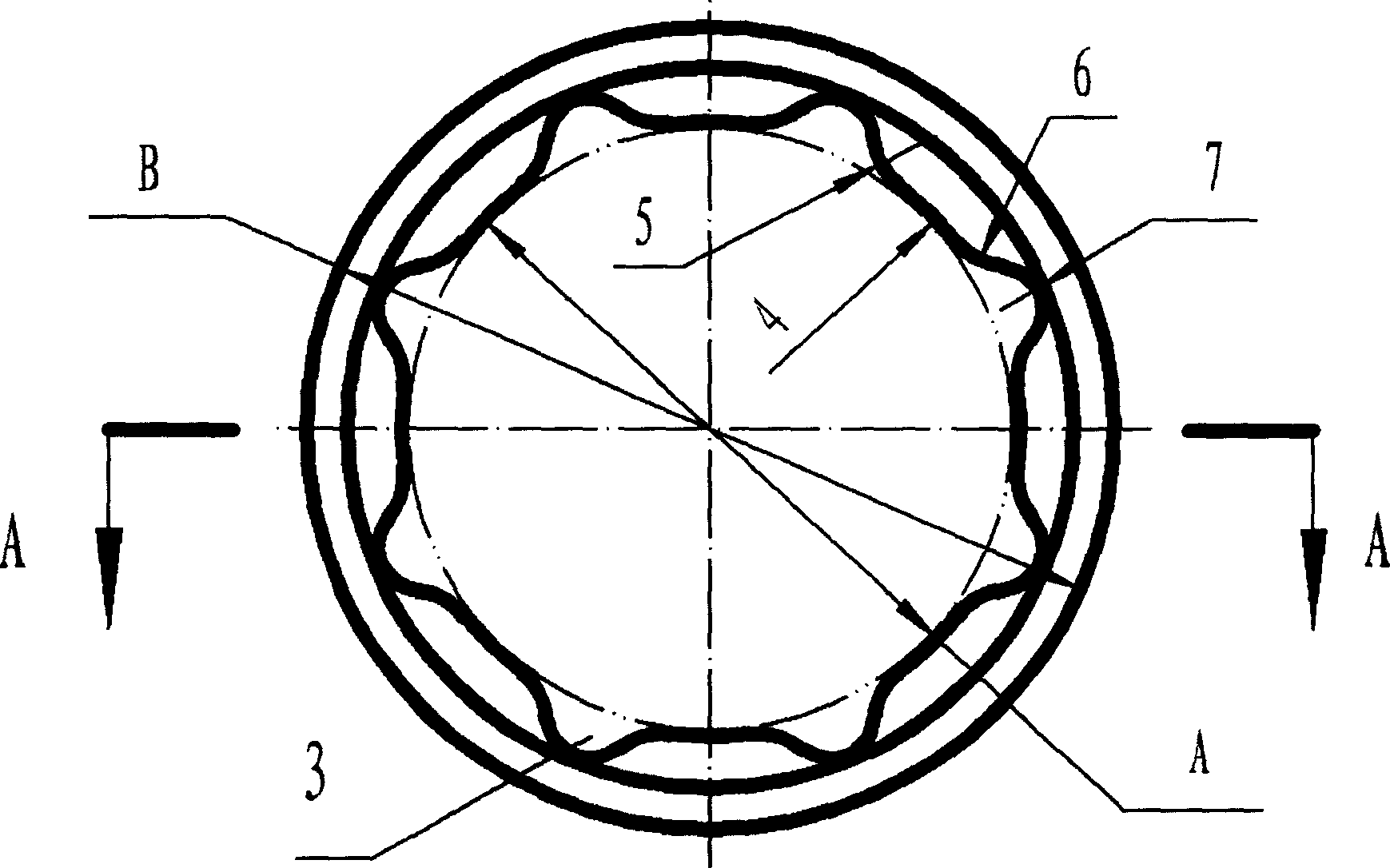

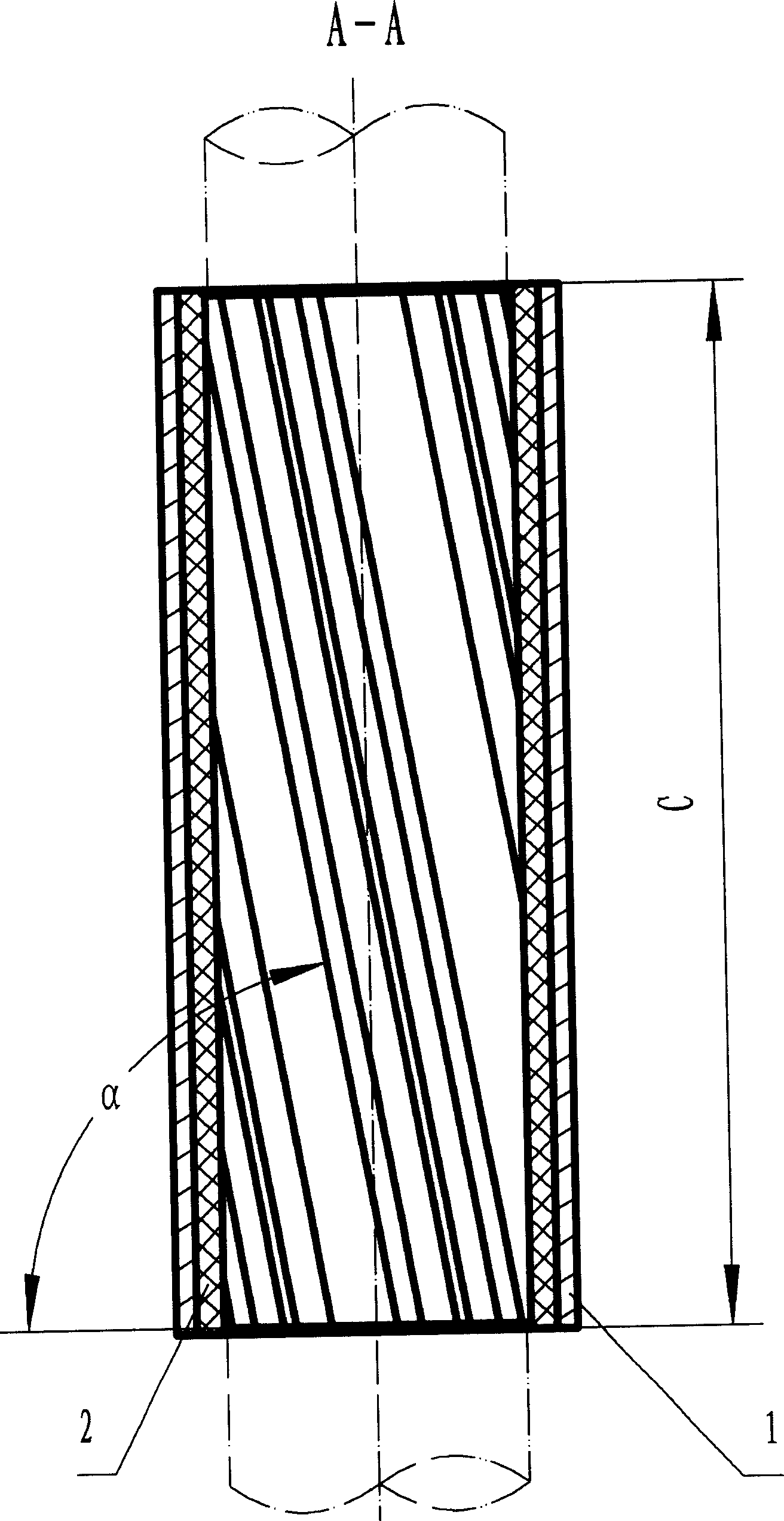

[0013] The spiral groove water lubricated rubber alloy bearing involved in the present invention, such as figure 2 Shown consists of a metal or non-metal shell 1 and a special rubber alloy inner bushing 2. Such as figure 1 As shown in the lubricating structure of the special rubber alloy inner bush 2, the spiral arc grooves 3 are designed to be evenly distributed in the circumferential direction and spirally distributed in the axial direction. The number of spiral arc grooves 3 can be multiple, and the spiral arc grooves The arc radius of groove 3 is R 4 , the working surface of the adjacent spiral arc groove 3 is composed of the arc surface 6, the arc surface 5 and the arc surface 4, and the working surface is evenly distributed in the circumferential direction.

[0014] The working principle of the spiral groove water-lubricated rubber alloy bearing inn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap