Method for adjusting height and position of magnetic head

An adjustment method and magnetic head technology, which are applied in the arrangement of recording heads, configuration/installation of recording heads, driving/moving of recording heads, etc., can solve the problem of inconsistent adjustment accuracy of the height position of the magnetic head, uneven recovery of the substrate 112, and difficulty in predicting the substrate 112. Problems such as bending direction and bending amount, to achieve the effect of reducing the adjustment accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

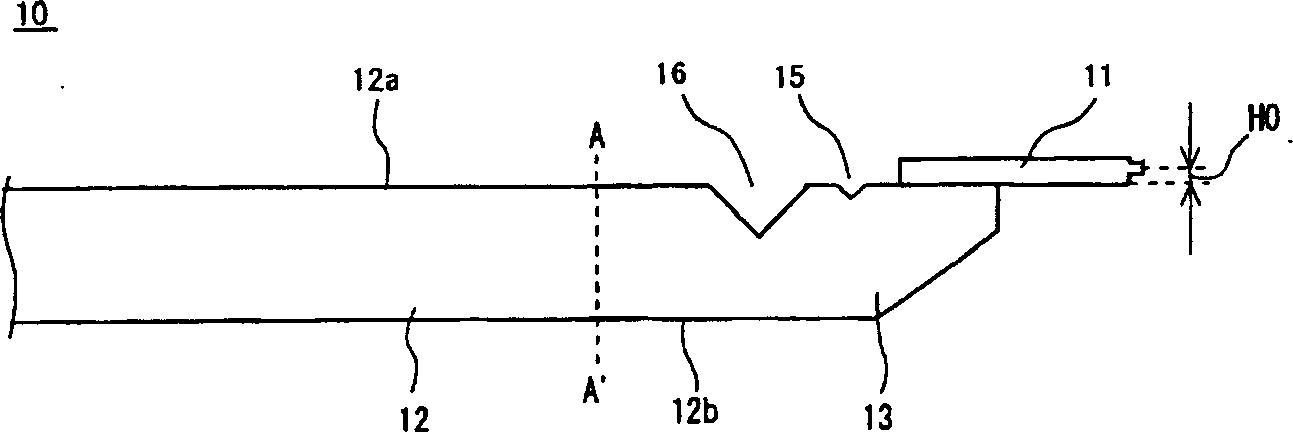

[0039] figure 1 It shows the magnetic head 10 before it is mounted on the rotary drum as the object of adjustment by the method of this invention. The magnetic head 10 has a magnetic head element 11 that performs recording and reproducing operations, and a substrate 12 that holds the magnetic head element 11 protruding from the tip of the magnetic head supporting surface 12 a.

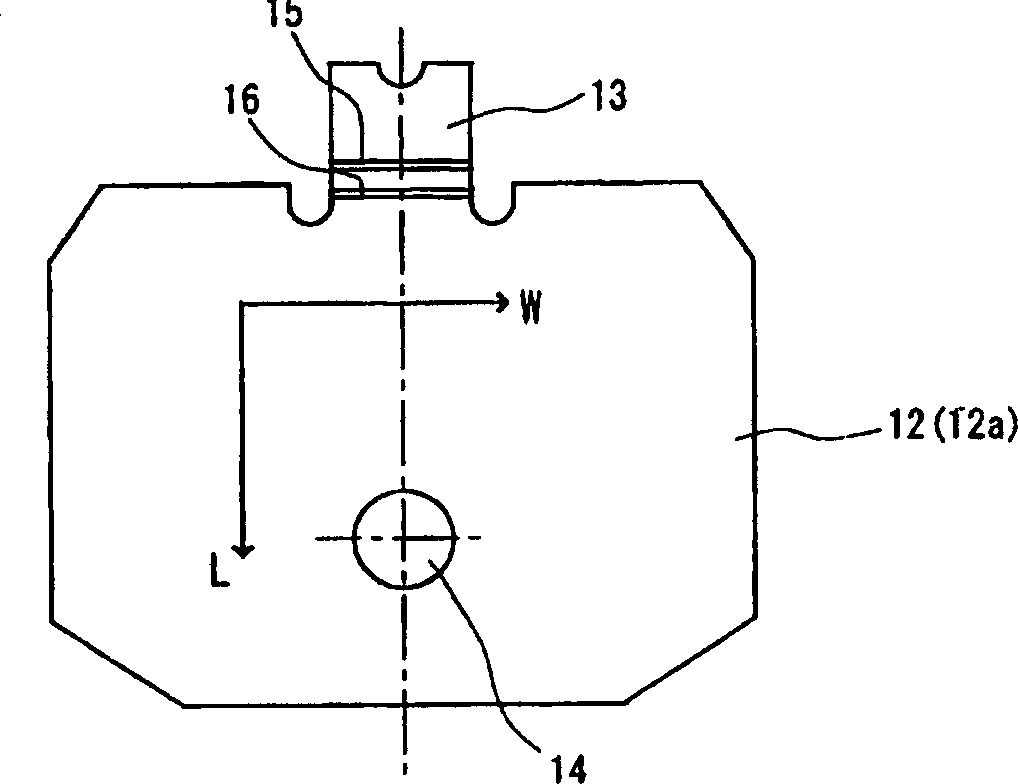

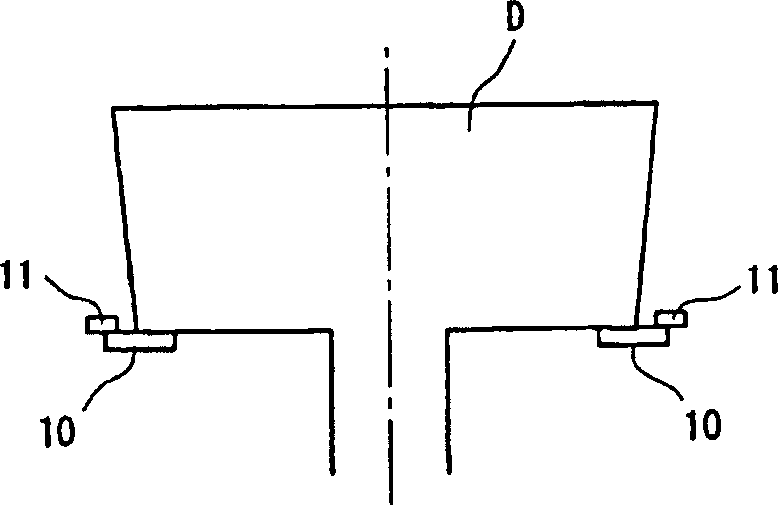

[0040] Such as figure 2 As shown, the substrate 12 is formed by a flat metal plate, and the metal plate has an elastic tongue part 13 at the top position to which the magnetic head element 11 is bonded and fixed, and a tongue part 13 at the center which is rotationally driven by a driving mechanism not shown. Rotating Drum D( image 3 ) Mounting holes 14 with free loading and unloading. figure 1 and Figure 4 The A-A' line shown by the middle dotted line is the bottom position of the semicircular space formed on the left and right sides of the elastic tongue part 13 in the figure. In this manua...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com