Frame assembly for vehicle and vehicle with the frame assembly

A frame and vehicle technology, which is applied to motor vehicles, bicycles, motorcycles, etc., can solve the problems of increasing vehicle weight and vehicle width, and achieve the effect of light weight and strength improvement, and realize the effect of light weight and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

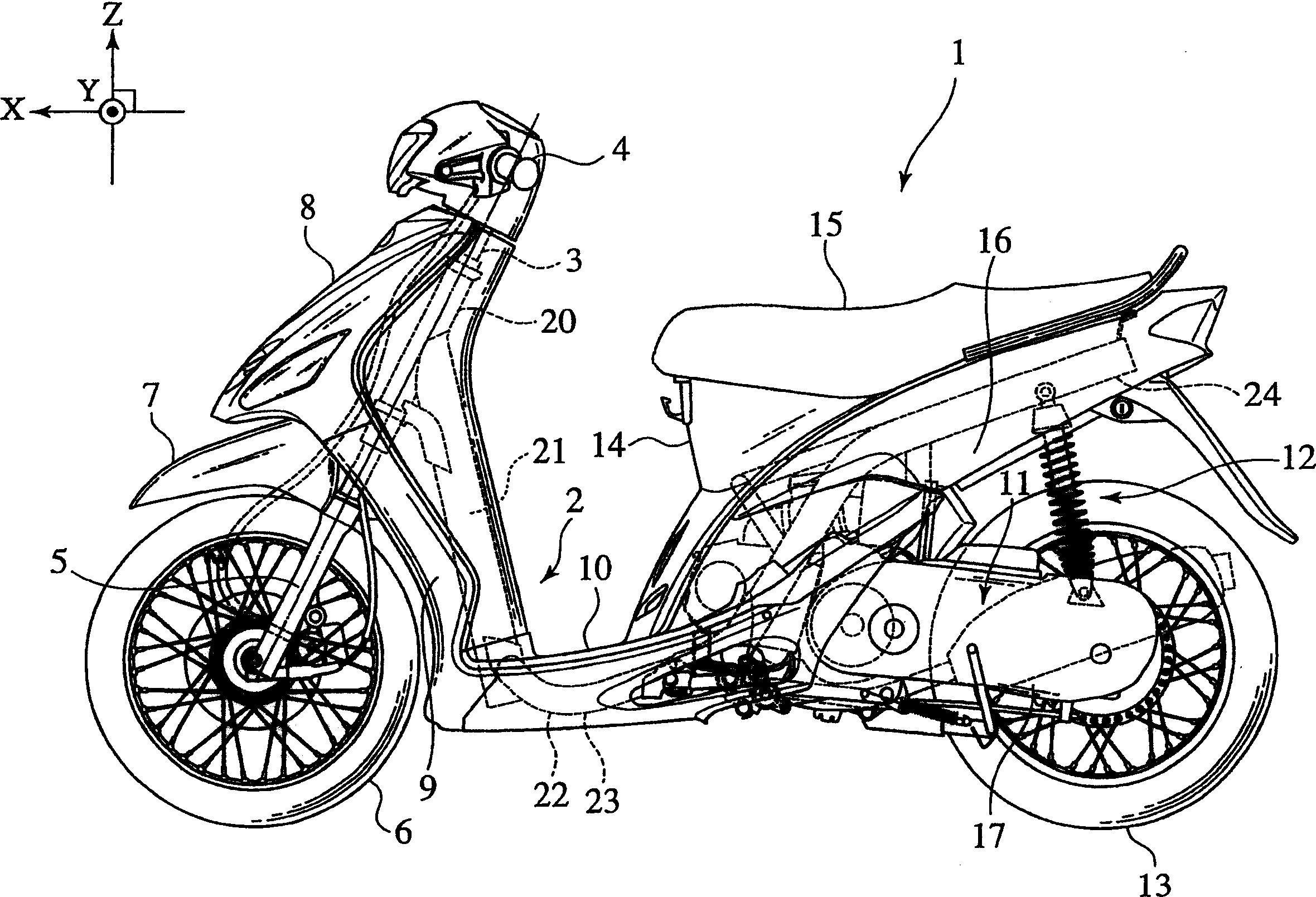

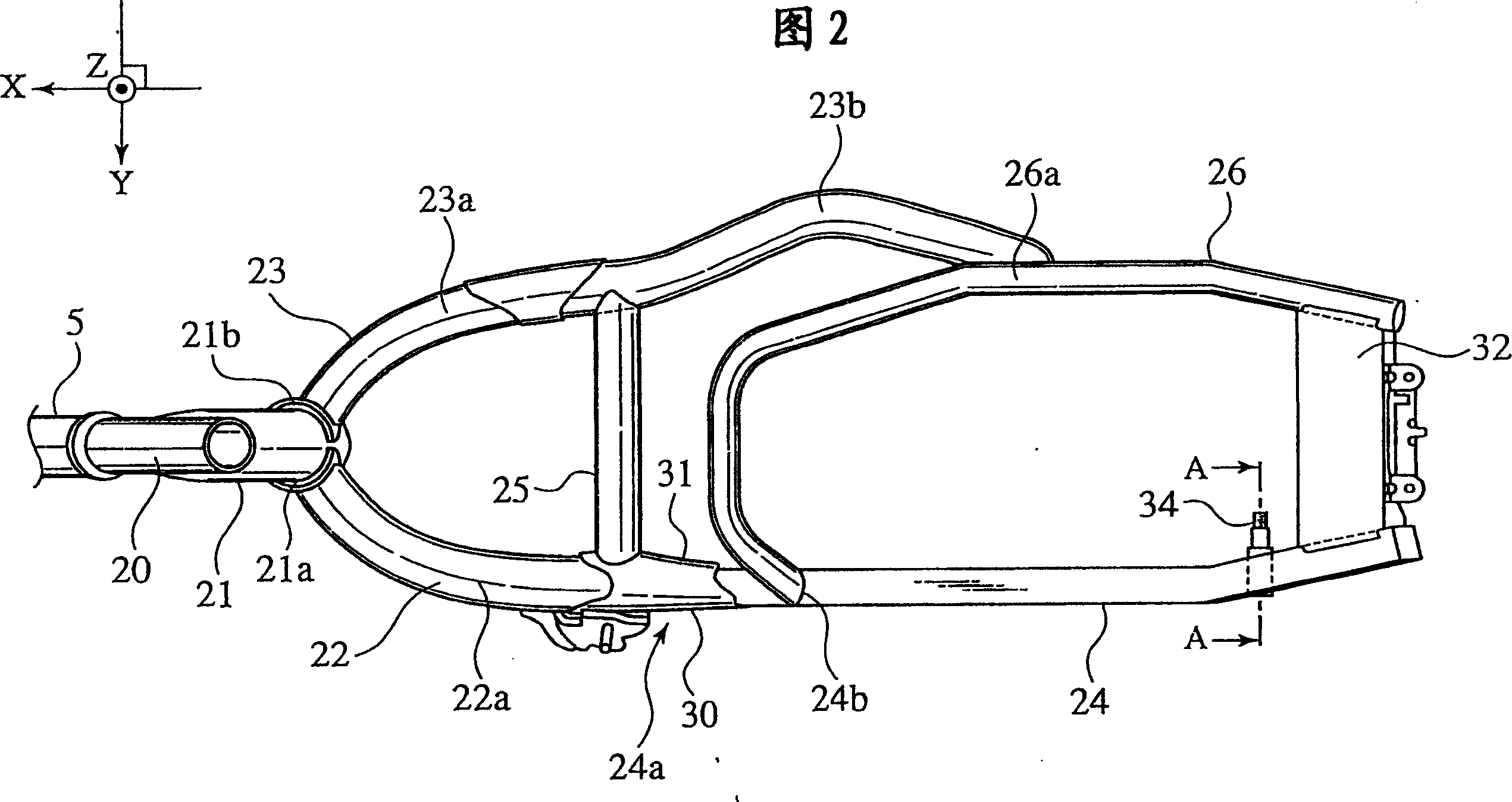

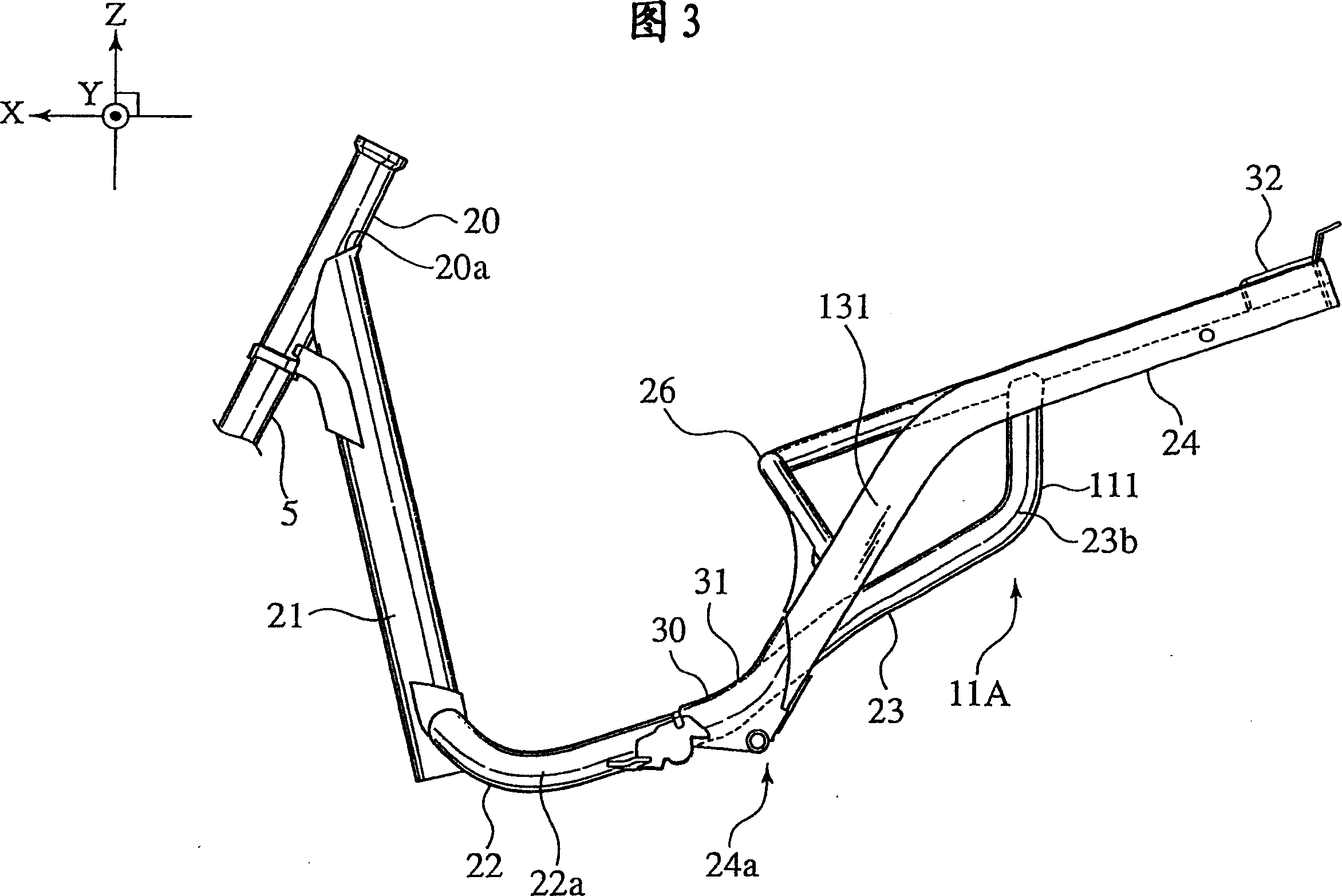

[0022] Below, refer to Figure 1 to Figure 6 , to illustrate an embodiment of the present invention. In these views, an X axis, a Y axis, and a Z axis are respectively set as the length direction, the width direction, and the height direction of the vehicle. The X axis, the Y axis and the Z axis are perpendicular to each other. In addition, in the present embodiment, terms such as pipes and tubes are used, but since these general concepts correspond to the vehicle frame, the above-mentioned terms and the vehicle frame can also be substituted.

[0023] Two-wheeled motorcycle 1 such as figure 1 As shown, it has: frame assembly 2, steering shaft 3, handle 4, front suspension 5, front wheel 6, front fender 7, front cover 8, front cover 9, pedals 10, engine 11, rear suspension Frame 12, rear wheel 13, storage box 14, seat 15, side cover 16 and transmission box 17.

[0024] The steering shaft 3 is rotatably penetrated through the head pipe 20 (one of the components of the frame ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com